In the quest for efficient oil extraction, selecting the right crude pump is crucial. Crude pumps play a vital role in transporting oil from the ground to processing facilities. As technology advances, new models offer improved performance and efficiency.

The 2026 best crude pump models promise innovative features that can enhance oil production. They are equipped with advanced materials and designs to minimize wear and tear. This leads to longer service life and lower maintenance costs. However, not every model is suitable for every situation. It's essential to consider the type of crude oil and extraction conditions.

Additionally, the market is filled with options, and it can be overwhelming. Some models promise high efficiency, but don't always deliver. Careful evaluation is required to ensure the investment pays off. Decision-makers must balance cost and performance. Ultimately, the right crude pump can significantly impact extraction efficiency and profitability.

In the world of oil extraction, choosing the right crude pump model is crucial. Different models offer varying levels of efficiency and performance. Some pumps excel in high-pressure environments, while others are designed for durability over long periods. Each model has unique features that cater to specific extraction needs. Understanding these features helps operators make informed decisions.

Efficiency is not only about the pump's mechanics. It also involves considering the entire oil extraction process. Factors like installation, maintenance, and operational conditions can significantly impact performance. Operators may notice that a pump performs well initially but faces challenges over time. Regular assessments and adjustments might be necessary to optimize function.

Many operators find that their initial choices do not meet expectations. This gap often requires revisiting equipment specifications and learning more about operational needs. Trials and feedback play a vital role in improving selection criteria. Engaging with experts can also provide valuable insights into the evolving nature of crude pump technology. The journey to finding the right model is continuous and requires dedication.

In 2026, crude pumps are vital for oil extraction efficiency. Top models showcase essential features that stand out in the industry. First, they offer enhanced durability. High-quality materials withstand harsh conditions. This reduces the need for frequent replacements. A reliable pump minimizes downtime and boosts productivity.

Another key aspect is energy efficiency. Modern pumps are designed to lower power consumption. This not only cuts costs but also aligns with environmental goals. Some pumps include smart technology that optimizes performance. Sensors monitor oil flow, allowing for real-time adjustments. This is crucial for maintaining extraction rates.

Yet, challenges remain. Not all pumps perform well in every environment. Operators must evaluate specific site conditions before selection. Additionally, user training is often overlooked. Proper knowledge can significantly impact the pump's effectiveness. Balancing technology with human operation is a continuous journey for improvement.

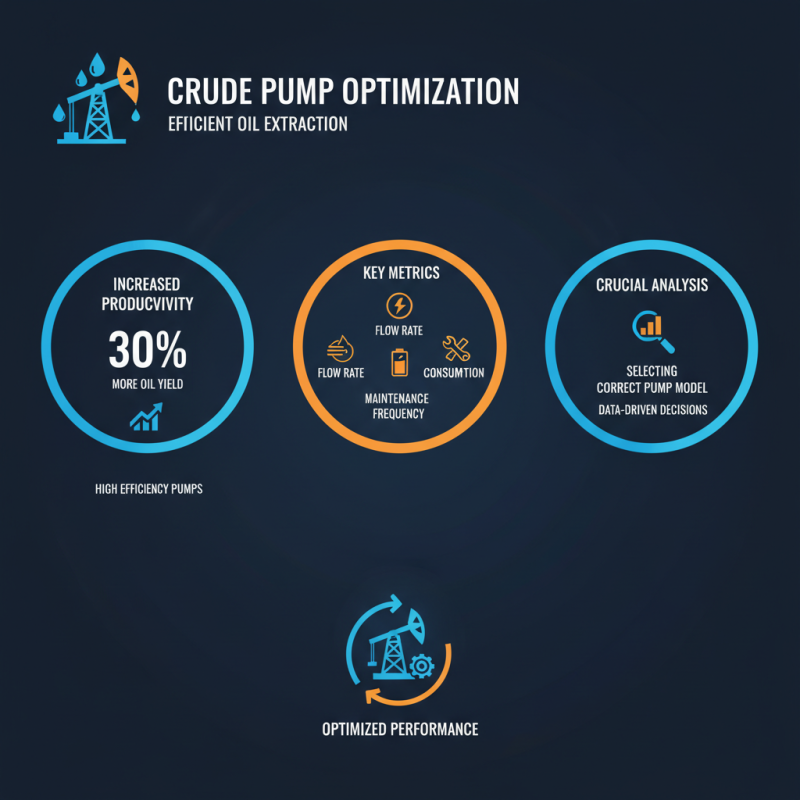

This chart displays the efficiency ratings of the top crude pump models based on their maximum flow rates (in liters per minute) and operational efficiency percentages measured in 2026.

In the quest for efficient oil extraction, analyzing performance metrics is crucial. The right crude pump model can significantly enhance productivity. Research shows that pumps with a high efficiency rating can yield up to 30% more oil. However, selecting the correct metrics is essential. Parameters like flow rate, energy consumption, and maintenance frequency play a vital role.

Flow rate, measured in gallons per minute, is a fundamental metric. Pumps exceeding 500 GPM usually optimize extraction. Energy consumption, measured in kilowatt-hours, influences operational costs. A study indicates that reducing energy use by 15% can lower expenses greatly over time. Maintenance frequency, too, cannot be overlooked. Many operators face unexpected downtime due to maintenance issues. Reports suggest that pumps requiring frequent repairs can lead to significant production losses.

While manufacturers promote high-performance pumps, not all models live up to their promises. Some models may show high initial efficiency but decline swiftly. Regular monitoring of performance metrics can help operators identify issues early. Understanding the imperfections of various models is necessary for improvement. It is often a challenge to find a balance between performance and reliability. Continuous evaluation is key in this evolving industry.

When selecting crude pump models, efficiency and reliability are key. A recent industry report highlights that inefficient pumps can lead to increased downtime and higher operational costs. On average, companies may lose up to 15% of their productivity due to suboptimal pumping solutions. It’s essential to compare pump specifications carefully before making a choice.

Leading crude pump brands offer a range of options, with varying performance metrics. Some models boast flow rates exceeding 10,000 barrels per day, while others focus on lower capacities but promise increased energy efficiency. However, these high-performance pumps often come with complex maintenance requirements, which can challenge operators. A survey indicates that 30% of users reported issues with maintenance frequency, underscoring the importance of durability in design.

Moreover, different materials used in pump construction can also impact longevity. For example, pumps made of advanced alloys may resist corrosion better. Yet, these benefits may come at a higher initial cost. Almost 25% of purchasers rethink their decision after experiencing unexpected wear and tear. Understanding the trade-offs in pump selection begins with in-depth market analysis and peer reviews.

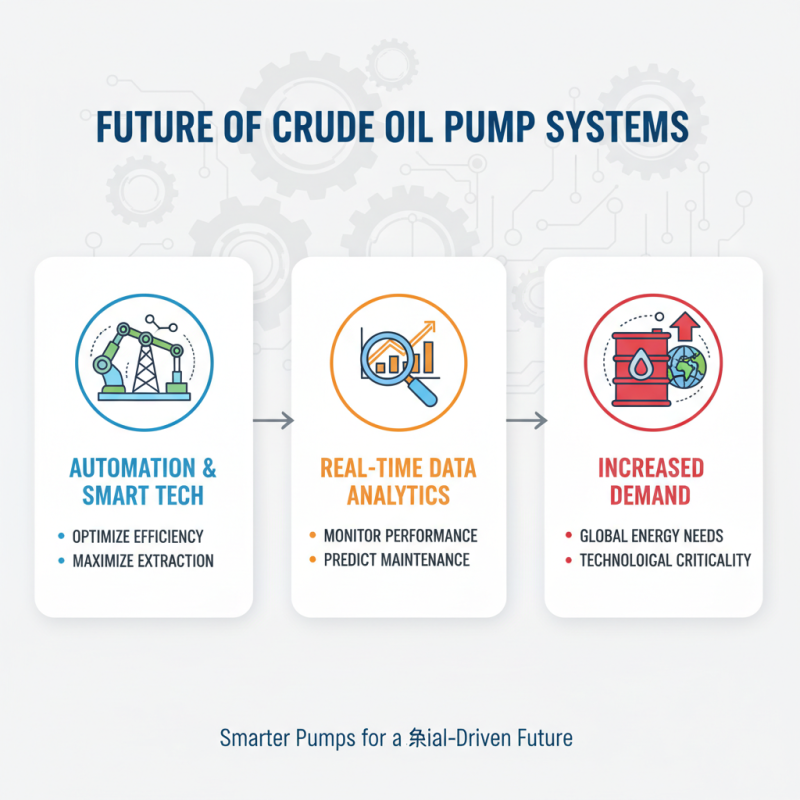

As the demand for oil continues to rise, the technological advancements in crude pump systems become critical. Future trends emphasize automation and smart technology integration. These systems will not only optimize efficiency but also maximize extraction rates. Implementing real-time data analytics can help monitor pump performance, predicting maintenance needs before issues arise.

Additionally, eco-friendly innovations are on the horizon. The emphasis on reducing carbon footprints has prompted new designs that enhance energy efficiency. Such pumps could use alternative power sources, minimizing environmental impact. However, the transition won’t be seamless. Many older models will face compatibility issues, making upgrades a daunting challenge for some operators.

Moreover, the industry's reliance on skilled labor needs reflection. As automation takes the spotlight, there is a risk of reducing jobs. Finding the right balance between technology and workforce needs is essential. Training programs must advance alongside the tech to ensure workers remain integral to the oil extraction process. The future is promising, but careful considerations are necessary.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.