Choosing the right oil pump for gear oil is crucial for optimal performance. In 2026, various options abound, yet not all pumps meet the required standards. Understanding what to look for can help navigate this complex market.

When selecting an oil pump for gear oil, consider the flow rate and the pump's compatibility with your vehicle. Some pumps are designed for high viscosity, while others may falter under pressure. Look for durable materials that can withstand harsh conditions. Reliability is a key factor.

Also, consider installation and maintenance needs. A pump that is hard to install might lead to overlooked problems later on. Sometimes, users may overlook essential specifications, leading to potential issues down the line. Reflecting on past choices can guide better decisions in selecting the right oil pump for gear oil.

When choosing the best oil pump for gear oil in 2026, several factors play a critical role. Performance is key. An efficient oil pump can enhance the lifespan of machinery. According to a recent report by the International Journal of Mechanical Engineering, the right oil pump can increase operational efficiency by up to 15%. This makes understanding pump characteristics essential for informed choices.

Durability is another defining factor. Well-constructed oil pumps can withstand high pressure and temperature. Data indicates that pumps made from specific materials tend to last significantly longer. They can endure harsh environments without failure. However, balancing cost and quality poses challenges. Not all expensive pumps guarantee reliability. Some inexpensive options perform surprisingly well.

Installation and maintenance also deserve attention. Many users overlook these aspects, leading to costly errors. A complex installation process may cause long-term issues. Moreover, regular maintenance is vital to ensure ongoing performance. Industry studies suggest nearly 30% of pump failures arise from inadequate maintenance. Emphasizing proper upkeep can mitigate many common pitfalls.

When choosing a gear oil pump, several key features matter. The pump's flow rate plays a crucial role in performance. A higher flow rate means quicker lubrication. This can help reduce wear in mechanical systems. It's essential to select a pump that can meet your specific needs.

Another important aspect is the pump's durability. Look for materials that withstand wear and harsh conditions. Pumps made from high-quality metals or composites often provide better longevity. However, some pumps may falter under extreme temperatures. It's smart to consider the environment where the pump will operate.

Compatibility with your gear oil is also vital. Some oils have unique properties that require specialized pumps. Not all pumps handle all oil types well. Be cautious and review specs carefully. An ill-suited pump can lead to inefficiency or even damage. Ultimately, it's about balancing performance and reliability.

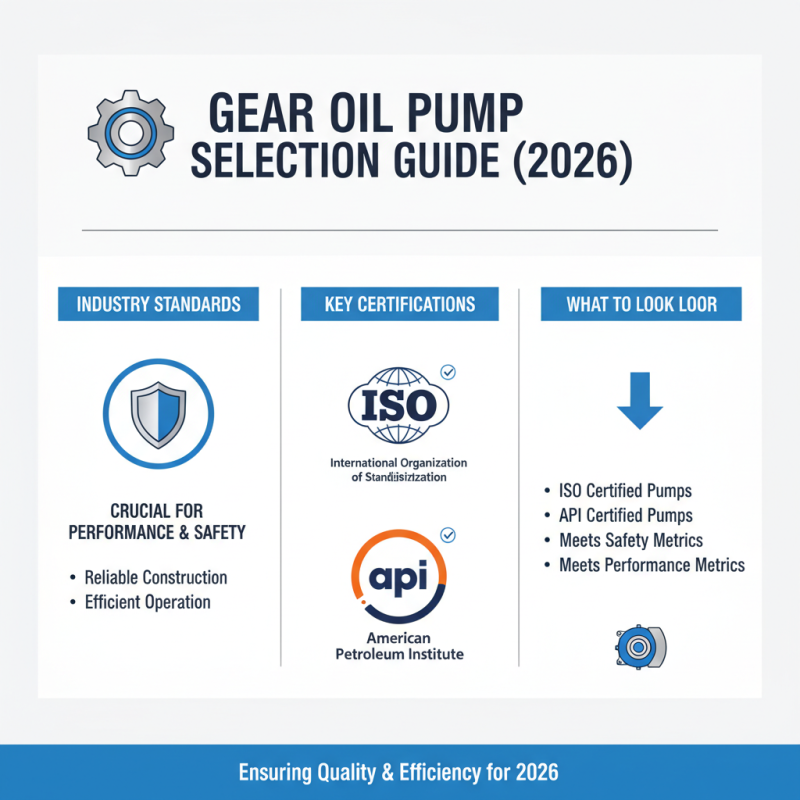

When selecting the best oil pump for gear oil in 2026, industry standards play a crucial role. Various certifications ensure that pumps meet specific performance and safety metrics. Look for pumps that comply with ISO and API standards. These certifications often indicate reliable construction and efficient operation.

Safety is another critical factor to consider. Many pumps are designed with features to minimize risks. However, not all may function optimally over time, leading to potential hazards. Regular maintenance and adherence to guidelines can help mitigate these issues.

Efficiency ratings are essential as well. A pump that consumes more energy than necessary can increase operational costs. Check specifications to ensure energy efficiency aligns with broader sustainability goals. Remember, even with certifications, real-world performance can vary. It's important to gather real user feedback before making a purchase decision.

Choosing the right oil pump for gear oil involves several factors. Efficiency is key. You want a pump that minimizes oil wastage. Consider the flow rate, as it directly impacts performance. A slow flow can lead to inadequate lubrication. On the other hand, excessive flow can cause overheating. Look for models that balance these aspects.

Durability matters too. Pumps made from high-quality materials often last longer. A sturdy design can handle pressure without failure. Not all pumps are equal, and some may not perform well in challenging conditions. It's essential to check user reviews and feedback. This gives insight into real-world performance and reliability.

Noise levels can be an overlooked detail. A quieter pump may be more desirable, especially in residential areas. Some models claim to reduce noise but may fall short in performance. It's important to prioritize both effectiveness and quiet operation. Balancing all these factors can be complex. A clear understanding of your needs will guide you to the right choice.

Oil pumps play a crucial role in maintaining the efficiency of gear oil systems. Regular maintenance is essential for extending their lifespan. One important aspect is keeping the pump clean. Dirt and debris can cause wear and tear. Regularly inspect the pump and remove any accumulated grime.

Another key factor is ensuring proper lubrication. Using the right oil viscosity is vital. Over time, oil degrades and loses its protective properties. This can lead to increased friction and potential failure. Regularly check the oil levels and replace old oil to ensure smooth operation.

Vibrations may indicate that the pump is not working properly. Monitor for unusual sounds or movement. Addressing small issues early can prevent costly repairs. Also, don’t forget to check all connections for tightness. Loose fittings can lead to leaks and decreased performance. The goal is to maintain efficiency and avoid unexpected breakdowns.

| Feature | Description | Maintenance Tip |

|---|---|---|

| Pump Type | Choose between gear, rotary, or diaphragm pumps based on your application. | Regularly check for compatible fluids to avoid pump damage. |

| Flow Rate | Select a pump with an appropriate flow rate for your operation. | Monitor flow rate regularly to detect any decrease due to wear. |

| Material Quality | Pumps made of high-quality materials resist wear and corrosion. | Perform visual inspections for signs of corrosion or wear. |

| Noise Level | Opt for quieter models if noise is a concern in your environment. | Keep pumps clean and properly lubricated to reduce noise. |

| Ease of Maintenance | Pumps designed for easy access and maintenance save time. | Create a maintenance schedule to ensure timely servicing. |

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.