In the rapidly evolving landscape of the supplier water pump industry, selecting the right equipment is crucial. According to the latest market analysis by Global Industry Analysts, the water pump market is projected to reach $75 billion by 2025. This growth underscores the vital role supplier water pumps play in various sectors, including agriculture, construction, and municipal services. These pumps are necessary for efficiently moving water and managing resources.

Experts like Dr. Emily T. Carson, a leading figure in hydraulic engineering, emphasize the importance of proper selection. She states, "The right supplier water pump can significantly impact both operational efficiency and cost-effectiveness." However, many suppliers struggle to meet diverse needs. They often focus more on cost than quality or efficiency, which can lead to performance shortcomings.

Even seasoned professionals face challenges in navigating features and specifications. Many suppliers offer options that may not suit all applications. As the dynamics of this industry change, users must stay informed on technological advancements. Finding the best supplier water pump requires due diligence and an understanding of specific requirements.

When exploring water pumps, understanding the various types available is crucial. Centrifugal pumps are commonly used in agriculture and industrial applications. They employ rotational energy to move water. In fact, market analysis indicates that centrifugal pumps account for over 40% of the global pump market.

Submersible pumps are another popular choice. These devices are designed to operate underwater, making them ideal for wells and sewage applications. They are efficient but can be tricky to maintain. Many users overlook maintenance, leading to premature failure.

Tip: Regularly inspect pump components. Look for signs of wear, and replace parts before they fail. This proactive approach can save time and money.

Positive displacement pumps offer a different mechanism. They push fluid through a system rather than relying on centrifugal force. This type is beneficial in applications requiring precise flow measurements. However, their installation and operating costs can be higher.

Tip: Analyze your specific needs before choosing a pump type. Understanding your requirements ensures better efficiency. It’s essential to balance cost and performance to avoid future regrets. Embrace the learning process, as each pump type has its strengths and weaknesses.

| Pump Type | Max Flow Rate (GPM) | Head (Feet) | Power Source | Efficiency Rating |

|---|---|---|---|---|

| Submersible Pump | 50 | 30 | Electric | 4.5/5 |

| Centrifugal Pump | 40 | 25 | Gasoline | 4.0/5 |

| Diaphragm Pump | 30 | 20 | Manual | 3.5/5 |

| Positive Displacement Pump | 45 | 40 | Electric | 4.6/5 |

| Solar Pump | 35 | 15 | Solar | 4.3/5 |

| Well Pump | 20 | 50 | Electric | 4.7/5 |

| Jet Pump | 25 | 30 | Gasoline | 3.8/5 |

| Sump Pump | 60 | 15 | Electric | 4.4/5 |

| Transfer Pump | 55 | 20 | Electric | 4.2/5 |

| Reef Pump | 30 | 10 | Electric | 4.1/5 |

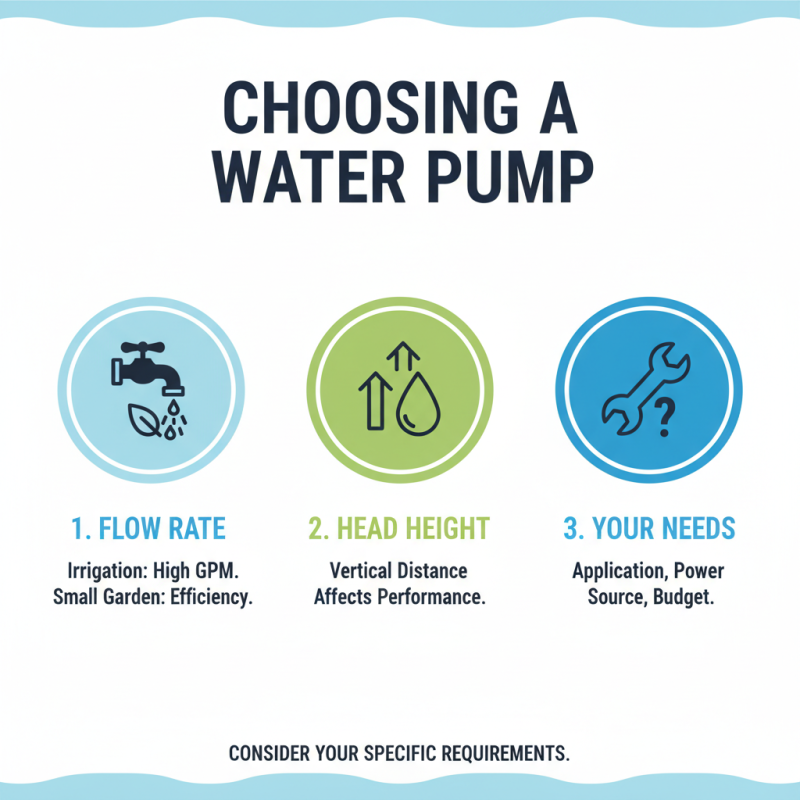

When choosing the right water pump, consider your specific needs. Think about the flow rate. How much water do you need to move? A high flow rate is crucial for irrigation, while efficiency may be better for smaller gardens. Assess the height the pump must lift water. This vertical distance affects performance.

Tips: Always measure the distance before buying. A simple calculation can save you time and money.

Next, consider the type of water source. Is it clean or dirty water? Submersible pumps are great for deep wells. Centrifugal pumps work well for clean sources. Each type serves different purposes.

Tips: If your water is murky, look for a pump with a filter to avoid clogs.

Lastly, think about maintenance. Some pumps require more upkeep than others. A lesser-known pump may save money but could become a hassle. It’s good to weigh reliability against cost. Don’t overlook warranty and support. A product that fails may leave you in a bind.

Tips: Check online reviews. They can reveal hidden problems before you commit.

Choosing the right water pump supplier can significantly affect your operations. Many factors influence this choice. Understanding key features is essential. Here are top features to consider when evaluating suppliers.

Pump efficiency is crucial. According to industry reports, a high-efficiency pump can save up to 20% on energy costs. Look for models with optimal performance curves. The material used in the pump is also important. Corrosion-resistant materials last longer in harsh conditions. This can reduce maintenance costs over time.

Tip: Always consider the warranty offered. A good warranty reflects confidence in the product.

Another vital feature is service support. Suppliers with responsive customer service can resolve issues quickly. Poor support can lead to operational downtime. Additionally, ensure the supplier has a good reputation in the market. Reviews and feedback from current users provide valuable insights.

Tip: Ask for references before finalizing any supplier. Having real-world feedback can help you make an informed choice.

A final consideration is the availability of spare parts. Having quick access to components is beneficial for maintenance. Not every supplier provides prompt parts service. This can pose challenges in urgent situations. Overall, think critically about these features to find the best supplier for your water pump needs.

When selecting a water pump, performance, efficiency, and cost are crucial factors. A recent industry report from Global Market Insights noted that efficiency in water pumps can affect operational costs significantly. For instance, high-efficiency pumps can save up to 30% in energy consumption compared to standard models. This translates directly to lower electricity bills for users.

The performance of a water pump often varies widely based on its design and application. Centrifugal pumps tend to deliver high flow rates and are ideal for large-scale tasks, while submersible pumps work best in confined spaces. Data shows that submersible pumps can operate at depths of up to 300 feet, making them versatile for both residential and industrial use. However, the upfront cost for these models can be higher, leading to important budget considerations.

Cost also plays a vital role in decision-making. While a lower-priced pump might seem appealing, hidden expenses can arise from lower efficiency and maintenance needs. Studies indicate that a higher initial investment in a quality pump can lead to savings over time. It's essential to analyze the total cost of ownership. This includes energy consumption, maintenance frequency, and lifespan. Making the right choice requires careful evaluation, and it's not always straightforward.

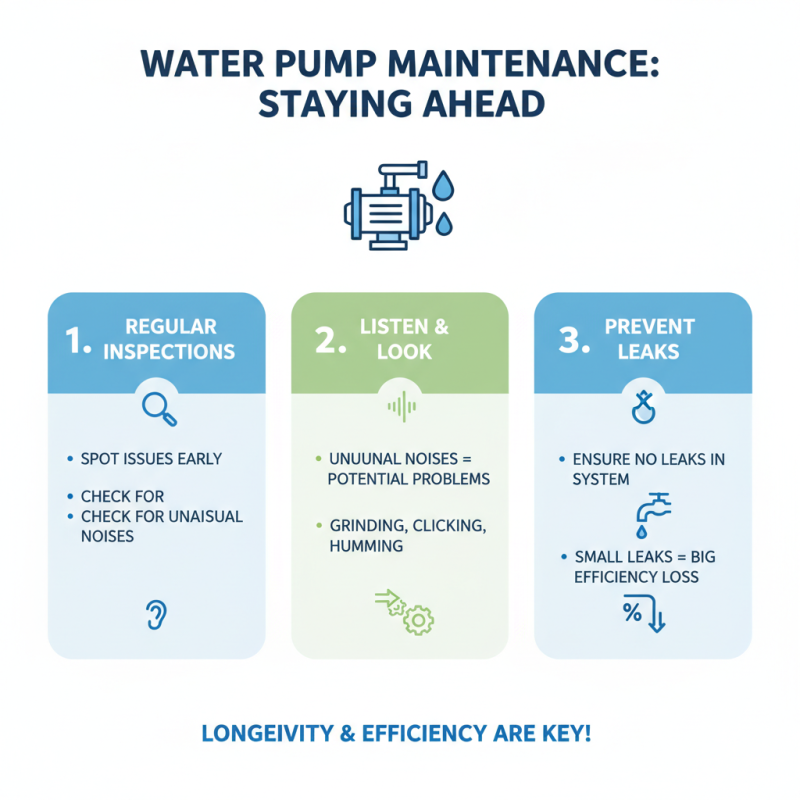

Maintaining your water pump system is crucial for its longevity. Regular inspections help spot issues early. Check for unusual noises. These can indicate potential problems. Additionally, ensure there are no leaks in the system. Even small leaks can lead to significant efficiency loss.

Another vital step is cleaning the filters. Clogged filters can strain the pump, leading to failure. Regularly replacing or cleaning them extends the pump's life. Also, monitor the pump's pressure. Abrupt changes can signal underlying issues. Address them before they escalate.

Ensure proper lubrication for moving parts. Lack of lubrication can cause wear and tear. Lastly, document maintenance activities. Keeping a log helps track when services were performed. It can also remind you of upcoming checks. Every action counts towards a better performing water pump system.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.