Choosing the right quality pumps for your needs in 2026 requires careful consideration. According to industry expert Dr. Emily Carter, “The key to selecting quality pumps lies in understanding your specific requirements.” Her insight emphasizes a thoughtful approach.

Quality pumps are essential in various applications, from agriculture to manufacturing. Different sectors demand different specifications. Understanding the performance metrics and durability is crucial. In addition, the pump's efficiency can significantly impact operational costs. Often, buyers overlook crucial aspects, leading to poor decisions.

Investing in quality pumps can save headaches later on. Various brands claim to offer the best quality. However, true quality is measured by reliability and customer support. Consulting experts or reviews can provide valuable insights. Emphasizing the right features will lead to better long-term outcomes. Make informed choices, and your operations will benefit significantly.

In 2026, understanding the various types of pumps is crucial for effective selection. Centrifugal pumps are among the most common. They work by converting rotational energy into hydraulic energy. These pumps are efficient for moving fluids with low viscosity. Reports indicate that over 50% of industries prefer centrifugal pumps for their reliability.

Another critical category is positive displacement pumps. These pumps move fluid by trapping a fixed amount and forcing it into the discharge. They excel in applications requiring high pressure. Notably, the global market for positive displacement pumps is projected to grow by 6% annually, reflecting their increasing importance.

When choosing a pump, consider the fluid's properties and desired flow rate. It's also essential to evaluate maintenance needs. Many users overlook this aspect, leading to efficiency losses. Being aware of industry standards helps avoid costly errors. Selecting the right pump type should align with operational requirements. Ignoring these factors can result in inadequate performance and increased expenses.

Choosing the right pump for your needs in 2026 involves understanding key performance metrics like efficiency and flow rate. Efficiency indicates how well the pump converts input energy into hydraulic energy. A more efficient pump saves you energy costs in the long run. On the other hand, flow rate refers to the volume of fluid a pump can move within a specific time. A higher flow rate might seem appealing, but it should match your system’s requirements.

Tips: Always assess your specific needs before selecting a pump. Consider the application environment. Is it a clean or contaminated fluid? Are there variations in viscosity? Understanding these factors is critical.

Performance metrics are not the only indicators of a pump’s quality. Installation conditions and maintenance practices also play a vital role. A high-efficiency pump might underperform if not installed correctly. Regular maintenance ensures consistency in flow rates and efficiency. You may need to adjust parameters as conditions change. Reflecting on these aspects will prevent future issues.

Choosing the right material for pumps is crucial. The pump's application determines the best material. For instance, corrosive liquids require materials like stainless steel or special alloys. These can withstand aggressive environments. According to industry reports, nearly 70% of pump failures are due to material incompatibility.

Plastic pumps serve well for non-corrosive fluids. They are lightweight and cost-effective. However, they might not handle high pressures. When selecting materials, consider temperature limits and chemical resistance. The wrong choices can lead to leaks or failures. A study by the Pump Industry Association indicates that nearly 40% of companies face unexpected downtime due to poor material decisions.

Reflection is necessary. Many companies often overlook the unique requirements of their applications. This can lead to substandard performance. Testing materials under real operating conditions is essential. Not all materials perform as expected when faced with actual use. Therefore, understanding the specific needs of your operation is vital.

When selecting the right pump for your needs, size and installation are crucial. Measure your available space accurately. A pump that’s too large can obstruct movement. Conversely, a smaller option might not meet your requirements. Assess the area where the pump will operate. Understand how much water or fluid you'll need to move.

Installation can often be challenging. Consider the location of power sources and plumbing connections. Insufficient electrical outlets or tight spaces can complicate setup. Find an area that allows for easy maintenance access. This can save you time and frustration down the line.

Pumps come in various styles and configurations. Some people overlook these specifics. Not every pump will fit every situation. Testing different options may feel daunting, but it's necessary. Rethink your choices based on actual performance, rather than assumptions. Adjustments may be needed after installation.

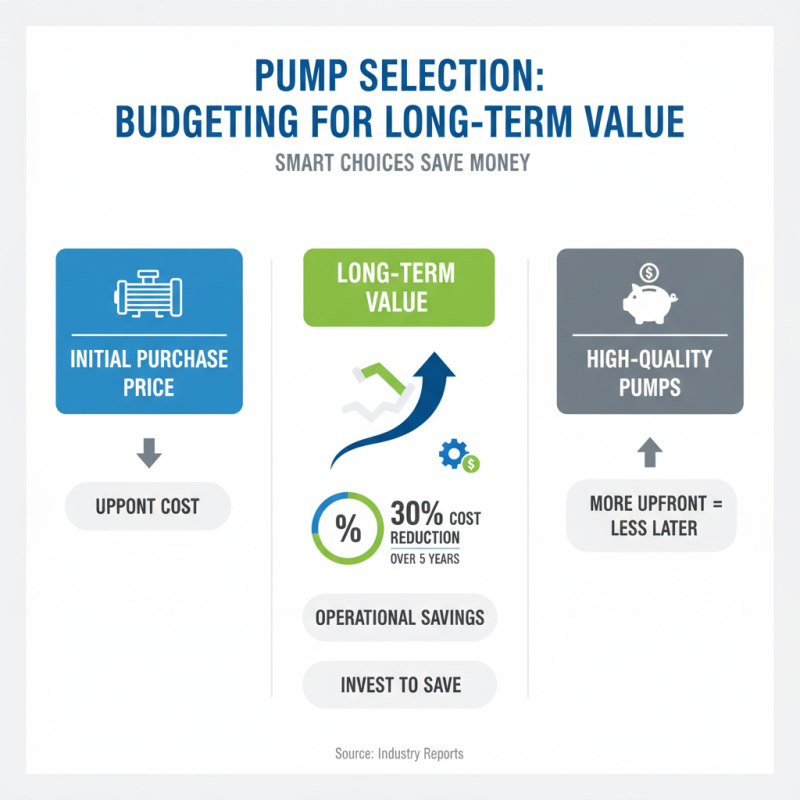

When selecting pumps, budgeting is crucial. It's not just about the initial purchase price. Long-term value plays a significant role. According to industry reports, high-quality pumps can reduce operational costs by 30% over five years. Investing more upfront may save money later.

Tip: Analyze your application needs carefully. A pump that fits today’s requirements might not sustain for future demands. Ensure flexibility for unexpected changes.

Consider maintenance costs too. Quality pumps may require less frequent repairs. Data indicates that a low-cost pump might cost 40% more in repairs over time. Cheaper isn’t always better.

Tip: Consult with experts to gauge your specific needs. Some pumps might seem affordable but could lead to inefficiencies. Reflect on the total cost of ownership. Are you focusing on immediate savings or long-term benefits? This choice defines your ROI.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.