In the rapidly evolving world of oil extraction, selecting the right crude pump is crucial for ensuring operational efficiency and maximizing output. Industry expert John Smith, a veteran in crude pump technology, once stated, "The right crude pump not only boosts productivity but also reduces maintenance costs and downtime." As the demand for oil continues to rise, understanding the factors that contribute to the optimal selection of a crude pump has never been more important.

With numerous options available on the market, making an informed decision can be overwhelming. The right crude pump should align with the specific needs of your extraction process, factoring in characteristics such as viscosity, flow rate, and the nature of the crude oil being pumped. Additionally, considerations regarding durability and the pump's compatibility with your existing infrastructure are critical to ensuring a seamless operation.

This guide aims to simplify the decision-making process, offering insights into the various types of crude pumps and their applications in the field of oil extraction. By equipping yourself with the right knowledge, you can confidently choose a crude pump that will meet your needs and contribute significantly to the success of your oil extraction efforts.

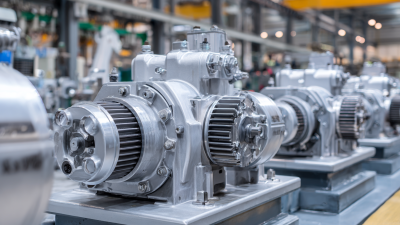

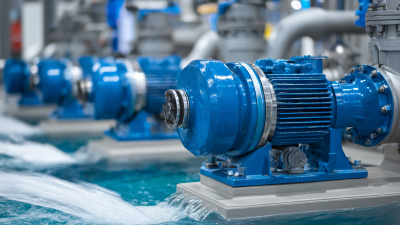

When selecting the right crude pump for oil extraction, it's essential to understand the differences between positive displacement pumps and centrifugal pumps. Positive displacement pumps are designed to move fluids by trapping a fixed amount of fluid and forcing it into the discharge pipe, making them ideal for handling viscous fluids and producing a consistent flow rate. On the other hand, centrifugal pumps utilize rotational energy to move fluids, providing higher flow rates and efficiency under low-viscosity conditions.

The global pumps market is projected to see significant growth, reaching an estimated USD 85.81 billion by 2031, up from USD 63.92 billion in 2024. This growth, with a compound annual growth rate (CAGR) of 4.30% from 2024 to 2031, indicates a rising demand for efficient pumping solutions in various sectors, including oil extraction. Understanding the specific requirements of each pump type can help companies optimize their operations and reduce costs, ultimately contributing to their competitive edge in the rapidly evolving oil market.

Choosing the right type of pump not only enhances productivity but also affects energy consumption and operational reliability. With the increasing focus on sustainability and efficiency in the oil industry, the decision between positive displacement and centrifugal pumps becomes even more crucial for maximizing resource extraction while minimizing environmental impact.

| Pump Type | Key Features | Best Use Cases | Pros | Cons |

|---|---|---|---|---|

| Positive Displacement | Handles viscous fluids, self-priming | Heavy crude oil, sludges | Efficient at high pressures, consistent flow rates | Can be harder to maintain, more wear and tear |

| Centrifugal Pumps | High flow rates, suitable for low viscosity | Light crude oil, refined products | Simple design, easy to maintain | Not effective with viscous fluids, less efficient at high pressures |

| Gear Pumps | Positive displacement, low shear | Lubricants, chemicals | Reliable operation, suitable for various viscosities | Can be expensive, requires precise alignment |

| Progressing Cavity Pumps | Handles solids and abrasives, continuous flow | Wastewater, food processing | Versatile with various media, low pulsation | Higher initial cost, requires regular maintenance |

When selecting a crude pump for oil extraction, key performance indicators (KPIs) such as flow rate and efficiency play a crucial role in determining the right fit for your needs. The flow rate, measured in gallons per minute or liters per second, indicates how much oil the pump can move within a specific time frame. A higher flow rate generally equates to greater productivity, but it is essential to match this with the operational capacity of the extraction system to avoid overburdening equipment and reducing overall efficiency.

Efficiency metrics, on the other hand, gauge how effectively a pump converts input energy into fluid movement. A highly efficient pump minimizes energy consumption while maximizing output, which can significantly reduce operational costs over time. When evaluating potential pumps, consider not only the initial cost but also the long-term energy savings and maintenance implications. Selecting a pump with the right balance of flow rate and efficiency ensures optimal performance, enhancing the overall productivity of your oil extraction operations while keeping costs manageable.

When selecting the appropriate crude pump for oil extraction, a critical aspect to consider is the

materials used in pump construction, particularly their

corrosion resistance and durability. In the oil production

industry, pumps are frequently exposed to harsh environments and corrosive substances, making the

choice of materials paramount for ensuring reliability and longevity.

Recent assessments indicate that materials such as high-grade stainless steel and specialized alloys can

significantly mitigate corrosion risks, enhancing the pump’s performance in extreme conditions often

encountered in Enhanced Oil Recovery (EOR) applications.

When selecting the appropriate crude pump for oil extraction, a critical aspect to consider is the

materials used in pump construction, particularly their

corrosion resistance and durability. In the oil production

industry, pumps are frequently exposed to harsh environments and corrosive substances, making the

choice of materials paramount for ensuring reliability and longevity.

Recent assessments indicate that materials such as high-grade stainless steel and specialized alloys can

significantly mitigate corrosion risks, enhancing the pump’s performance in extreme conditions often

encountered in Enhanced Oil Recovery (EOR) applications.

Moreover, technological advancements have led to the development of

composite materials that boast superior strength-to-weight

ratios and resistance to aggressive chemical processes. Reports project that the global market for such

innovative materials is anticipated to grow substantially over the next decade, driven by increasing

demands for efficiency and sustainability in oil extraction processes. As industry statistics show, the right

material choice can extend pump life by up to 30%,

ultimately contributing to reduced operational costs and improved profitability for oil extraction operations.

Thus, evaluating the materials used not only optimizes performance but is essential in meeting the

evolving challenges within the crude oil sector.

When selecting a crude pump for oil extraction, assessing the power requirements is crucial to ensure efficient operation. The energy consumption of a pump significantly affects the overall operational costs and should be a primary consideration. Each pump type has a distinct energy profile, influenced by its design, size, and the specific conditions of the extraction site. Therefore, conducting a detailed analysis of the energy requirements, including flow rate and pressure, is essential to match the pump's capabilities with the energy supply available.

Understanding the relationship between energy consumption and pump performance can lead to significant savings and improved efficiency. For instance, centrifugal pumps typically consume more energy than positive displacement pumps at a given flow rate, but they are often preferred for higher volume applications due to their efficiency at scale. By analyzing the energy consumption patterns during operation, operators can identify peak usage times and potential system optimizations, thus ensuring that chosen pumps do not excessively drain resources while maximizing output.

When selecting a crude pump for oil extraction, maintenance considerations play a pivotal role in ensuring the longevity and efficiency of the equipment. Regular inspections and routine maintenance are crucial to identify potential issues before they escalate. This includes checking for wear and tear on seals and bearings, as well as monitoring the pump's performance metrics to detect any irregularities in flow rates or pressure levels. Creating a structured maintenance schedule can help in prolonging the pump's life and minimizing unexpected downtimes.

Moreover, the operational environment of the crude pump significantly impacts its upkeep. Factors such as temperature fluctuations, exposure to corrosive substances, and the presence of particulates in the oil can all affect pump functionality. Using high-quality materials and protective coatings can mitigate some of these risks. Additionally, training personnel on proper operational protocols and emergency procedures can further enhance the pump's reliability in the field. Ensuring that maintenance practices are adhered to not only maximizes performance but also fosters a safer and more efficient extraction process.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.