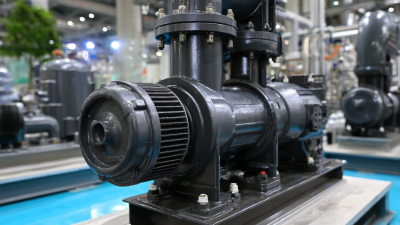

Choosing the right gear pumps for your industrial needs is a crucial decision that can significantly impact operational efficiency and productivity. According to a recent market research report from Research and Markets, the global gear pump market is expected to reach $5.2 billion by 2027, growing at a CAGR of 4.5% from 2020 to 2027. This growth is driven by the increasing demand for gear pumps in various sectors, including oil and gas, chemicals, and food processing, where reliability and precision are paramount.

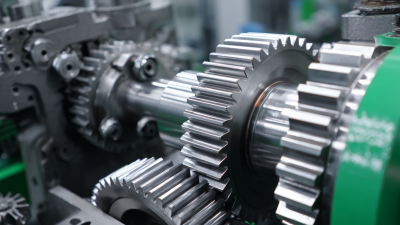

Gear pumps are widely recognized for their ability to handle high-viscosity fluids and provide consistent flow rates, making them an essential component in many industrial applications. However, with a diverse range of gear pumps available, selecting the right type for specific operational requirements involves a careful evaluation of various factors such as fluid characteristics, pressure ratings, and installation constraints. Understanding these criteria is key to making an informed choice that aligns with both current and future industrial needs.

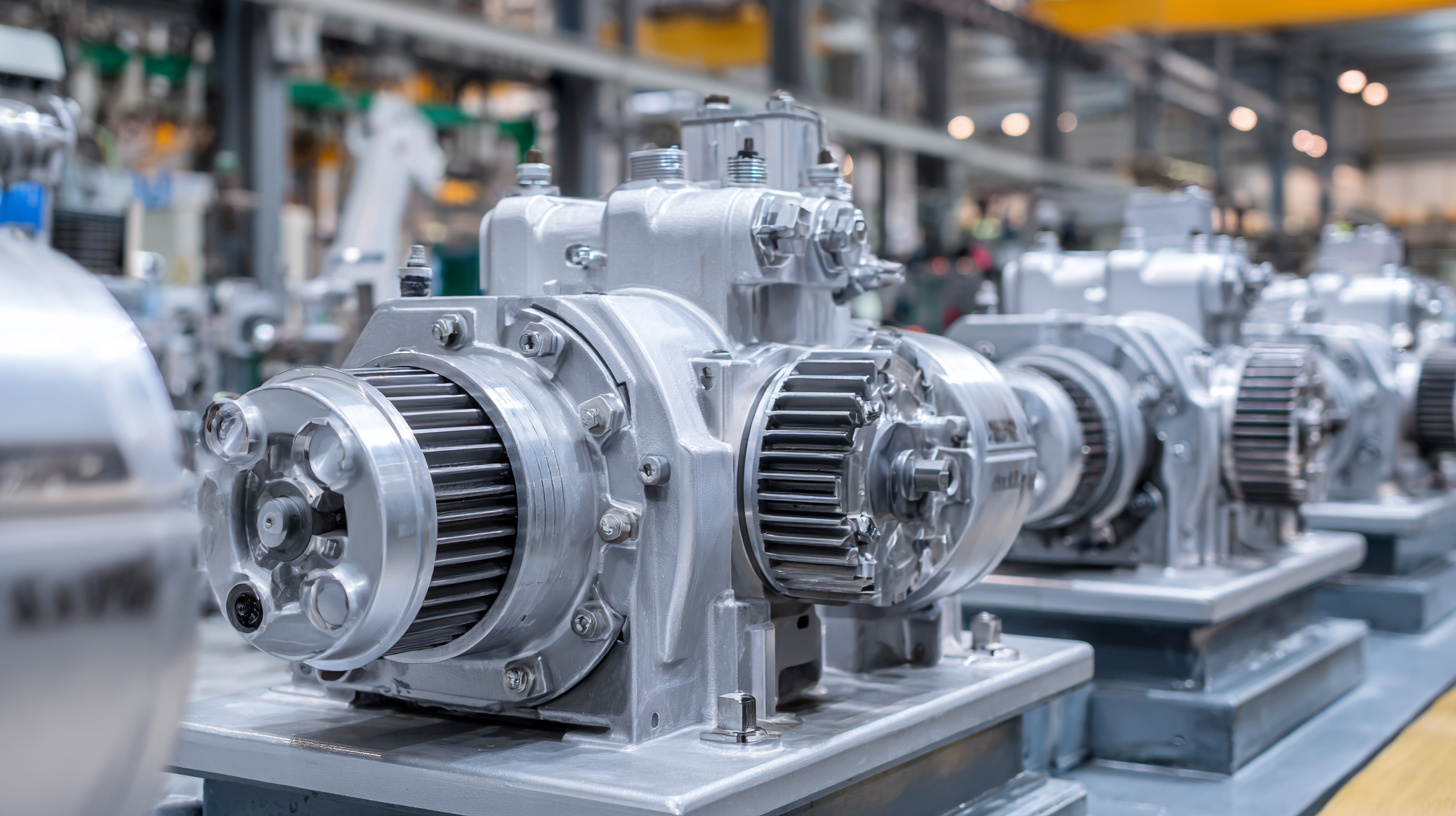

When selecting gear pumps for industrial applications, it is essential to understand the different types available and their specific benefits. Gear pumps are primarily categorized into two types: external gear pumps and internal gear pumps. External gear pumps consist of two gears that mesh together to move fluid, making them ideal for applications involving low to medium viscosity fluids. Their simple design allows for easy maintenance and reliable operation, which is crucial in industrial settings where downtime can be costly.

On the other hand, internal gear pumps, featuring an internal and an external gear, are better suited for handling higher viscosity fluids and providing consistent flow rates. They are particularly effective for applications requiring precise metering and are widely used in industries such as food processing and chemical manufacturing. Understanding the differences between these gear pump types will aid in selecting the right pump that aligns with specific operational needs, ensuring efficiency and productivity in industrial processes.

| Type of Gear Pump | Applications | Viscosity Range (cP) | Flow Rate (L/min) | Operating Pressure (bar) |

|---|---|---|---|---|

| External Gear Pump | Fuel transfer, hydraulic fluids | 10 - 1000 cP | 5 - 300 L/min | 5 - 20 bar |

| Internal Gear Pump | Chemical processing, oil and grease | 50 - 10000 cP | 3 - 150 L/min | 3 - 25 bar |

| Gear Pump with Magnetic Drive | Pharmaceuticals, food processing | 1 - 500 cP | 10 - 200 L/min | 1 - 10 bar |

| Helical Gear Pump | High viscosity fluids, asphalt | 100 - 100000 cP | 10 - 500 L/min | 10 - 30 bar |

When selecting the right gear pump for your industrial needs, it's essential to evaluate key performance metrics that will influence its effectiveness in your specific application. Flow rate is one of the most critical factors to consider, as it determines the volume of fluid the pump can move within a set timeframe. Understanding the required flow rate for your processes will help ensure that you choose a pump that can maintain operational efficiency without overloading or damaging the system.

When selecting the right gear pump for your industrial needs, it's essential to evaluate key performance metrics that will influence its effectiveness in your specific application. Flow rate is one of the most critical factors to consider, as it determines the volume of fluid the pump can move within a set timeframe. Understanding the required flow rate for your processes will help ensure that you choose a pump that can maintain operational efficiency without overloading or damaging the system.

Another vital aspect is pressure. Gear pumps are often utilized in applications requiring high pressure; thus, assessing the maximum pressure output of the pump is crucial to meeting operational demands. Additionally, efficiency plays a pivotal role in the selection process. A pump that operates efficiently will not only reduce energy consumption but also extend the lifespan of the equipment. By thoroughly analyzing these performance metrics — flow rate, pressure, and efficiency — you can make an informed decision that aligns with your industrial requirements and maximizes productivity.

When selecting gear pumps for industrial applications, one of the critical factors to consider is the compatibility of materials with the fluids they will be handling. According to a report by the Hydraulic Institute, nearly 60% of pump failures are attributed to material incompatibility. This underscores the importance of choosing materials that can withstand corrosive or viscous fluids without degrading over time.

For instance, when dealing with aggressive chemicals such as acids or solvents, pumps made from fluoropolymer or stainless steel are typically recommended. These materials offer excellent resistance to a wide range of chemicals. In contrast, for less aggressive environments where the fluid is primarily oil-based, standard aluminum or cast iron might suffice. A study from the American Society of Mechanical Engineers found that using the appropriate material can enhance pump longevity by up to 30%, thereby reducing maintenance costs and downtime.

Additionally, environmental conditions play a crucial role in material selection. For operating environments that experience extreme temperatures or potential exposure to environmental stressors, using materials with high thermal and structural stability, such as polyamide or reinforced composites, can significantly prolong the functional life of gear pumps. This careful alignment of material properties with both fluid characteristics and environmental conditions can greatly enhance operational efficiency in industrial settings.

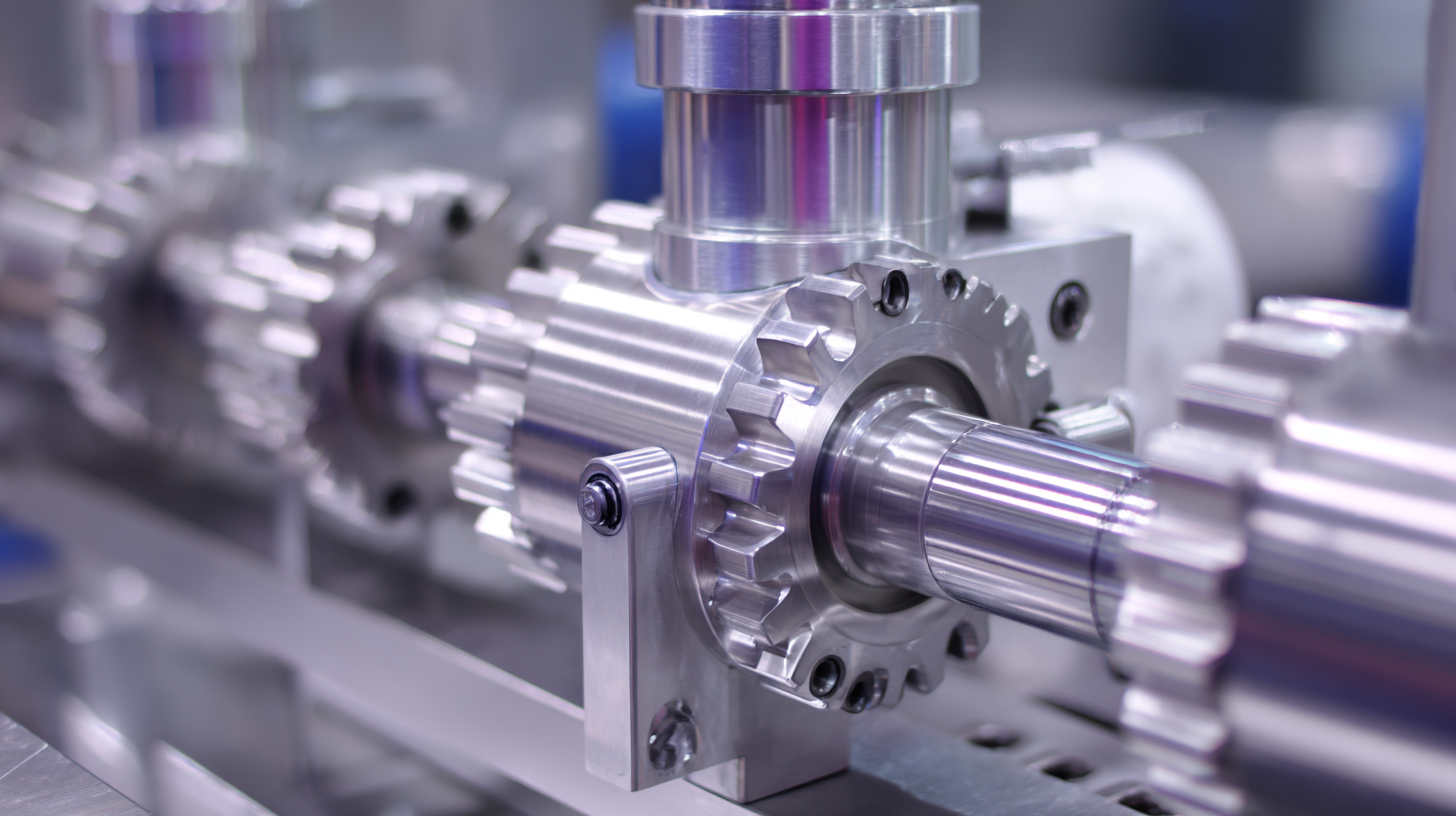

When selecting gear pumps for your industrial applications, sizing and installation are critical factors that can significantly impact performance. First, determine the flow rate requirements of your system. Gear pumps are designed for specific flow capacities, so it’s essential to match the pump’s output with the system's demands. Consider the system's viscosity as well, as thicker fluids may require a pump with a higher torque rating. Additionally, check for pressure requirements to ensure the chosen pump can handle the maximum operating pressure without failure.

Installation is equally important to ensure optimal operation of gear pumps. Begin by analyzing the layout of your system, taking care to position the pump appropriately to minimize energy losses from bends and elevation changes in the piping. Proper alignment is crucial to prevent premature wear and ensure sufficient clearance between gears. Furthermore, consider the accessibility for maintenance and monitoring; pumps that are easier to access can lead to reduced downtime and more efficient servicing. Following these key considerations will help you select and install gear pumps that enhance the efficiency and reliability of your industrial processes.

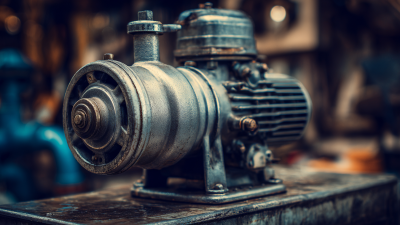

When it comes to the maintenance of industrial gear pumps, consistency is key to extending their lifespan and ensuring optimal performance. Regular inspections should be part of your routine maintenance practices. Check for signs of wear, leakage, or unusual noises, as these can indicate underlying issues that need to be addressed before they escalate. Additionally, maintaining correct lubrication is vital; ensuring the gear pumps are adequately lubricated helps reduce friction and prevents overheating.

**Tips:** Implement a scheduled maintenance program, which includes daily checks and monthly comprehensive reviews. Keep detailed records of the maintenance activities to track any patterns that may emerge over time.

Another essential maintenance practice involves the monitoring of the operating environment. Ensure that the pump is operated within its specified temperature and pressure ranges, as deviations can lead to premature wear and failure. Also, consider using filters to keep the pump’s fluid clean, which helps protect the internal components.

**Tips:** Train your staff on the importance of maintaining the operating conditions and provide them with the necessary tools and techniques to monitor these parameters effectively.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.