In the quest for the ideal water pump technology to meet diverse needs, understanding the various options available is crucial. As we approach 2025, advancements in water pump technology have made it essential for consumers to evaluate their specific requirements carefully. Whether for residential use, agricultural applications, or industrial processes, the right pump can enhance efficiency and reduce costs, making informed choices more important than ever.

Choosing the best water pump technology involves not only assessing the flow rates and pressure requirements but also considering factors such as energy consumption, maintenance, and durability. Additionally, as environmental concerns rise, selecting sustainable and eco-friendly options has become a priority. As this guide unfolds, we will delve into the key aspects that influence the decision-making process, ensuring you are well-equipped to select a water pump technology that aligns seamlessly with your unique needs and preferences. Together, we will navigate the complexities of water pump technologies to empower you in making an informed investment for the future.

When selecting the right water pump technology for your specific needs, it is crucial to first understand your requirements and applications. Begin by assessing the purpose of your water pump. Are you using it for residential use, agricultural purposes, or industrial applications? Each sector has unique demands that dictate the type of pump required. For instance, a home irrigation system may require a low-pressure pump, while an industrial facility might need a high-capacity pump capable of handling larger volumes of water over long distances.

In addition to the application, consider the characteristics of the water you will be pumping. Factors such as temperature, viscosity, and the presence of solids can significantly affect performance. Determine whether you will be pumping clean water, wastewater, or even corrosive liquids, as this will influence the materials and technology employed in the water pump. Also, consider the environment where the pump will be used—outdoor pumps need to withstand weather conditions, while indoor pumps may require quieter operation to minimize disruption. By carefully evaluating these requirements, you can select a water pump that not only meets your immediate needs but also provides efficient and reliable service over time.

| Pump Type | Capacity (GPM) | Head (Feet) | Power Source | Typical Applications |

|---|---|---|---|---|

| Centrifugal Pump | 10-1000 | 10-200 | Electric, Diesel | Irrigation, Water Supply, HVAC |

| Submersible Pump | 5-500 | 15-300 | Electric | Well Water, Sump Pumping |

| Diaphragm Pump | 1-200 | 5-100 | Electric, Pneumatic | Chemical Transfer, Wastewater Treatment |

| Gear Pump | 1-100 | 10-50 | Electric | Fuel Transfer, Lubrication |

| Peristaltic Pump | 0.1-80 | 5-30 | Electric | Medical, Food Processing |

When selecting the best water pump technology for your needs, it's crucial to understand the various types available and their corresponding applications.

Positive displacement pumps and centrifugal pumps are two primary categories to consider.

Positive displacement pumps work by trapping a fixed amount of liquid and forcing it out, making them ideal for applications requiring high viscosity fluids or precise dosing.

These pumps are known for their efficiency and ability to generate high pressure, making them suitable for industrial uses and specific agricultural applications.

On the other hand, centrifugal pumps utilize rotational energy to move fluid through the pump.

They are particularly effective for transporting large volumes of water at low pressure and are commonly used in municipal water supply systems and irrigation.

Their design allows for easy maintenance and operational flexibility across a variety of flow rates.

Ultimately, the choice between these types hinges on factors such as the specific fluid characteristics, required flow rate, pressure conditions, and the overall energy efficiency sought for your application.

Understanding these distinctions will help in making an informed decision tailored to your specific water transportation needs.

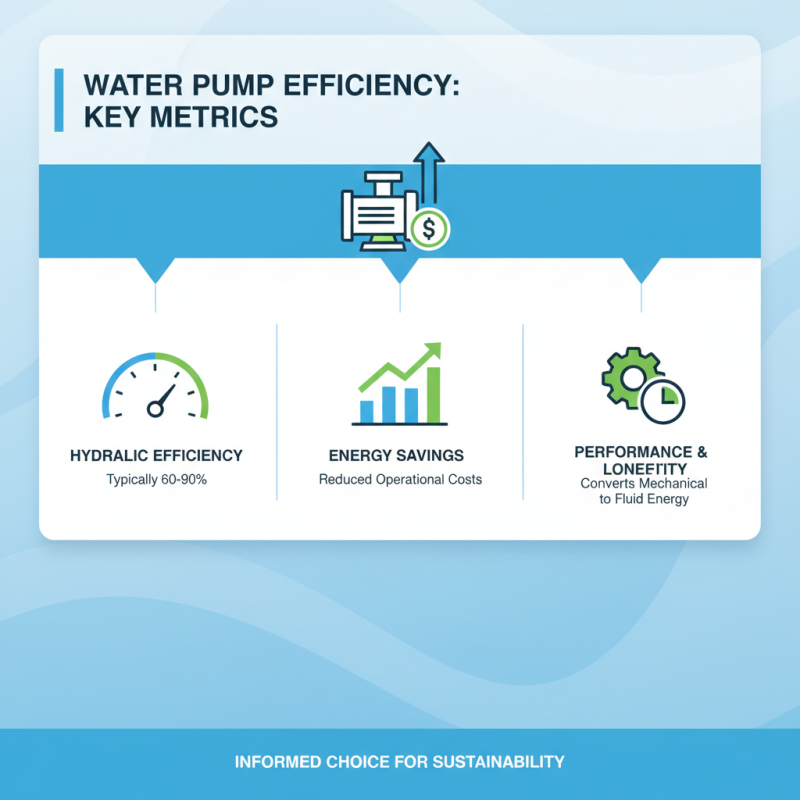

When selecting a water pump, understanding efficiency and performance metrics is crucial to making an informed choice that meets your needs. One of the key metrics to consider is the pump's hydraulic efficiency, which typically ranges from 60% to 90%. According to a report by the Hydraulic Institute, improving hydraulic efficiency can lead to significant energy savings, translating to reduced operational costs over time. This efficiency indicates how well the pump converts mechanical energy into fluid energy and can impact not only performance but also the longevity of the pump.

Another important performance metric is the flow rate, which is often measured in gallons per minute (GPM) or liters per second (L/s). Industry standards suggest assessing the specific requirements of your application, as pumps are often rated for optimal performance at particular flow rates. For instance, the American Society of Mechanical Engineers (ASME) highlights that selecting a pump that operates near its Best Efficiency Point (BEP) can enhance performance and reduce maintenance issues. Furthermore, ongoing developments in pump technology, including variable frequency drives (VFDs), allow for better control over flow rates and energy consumption, making them a vital consideration in the decision-making process.

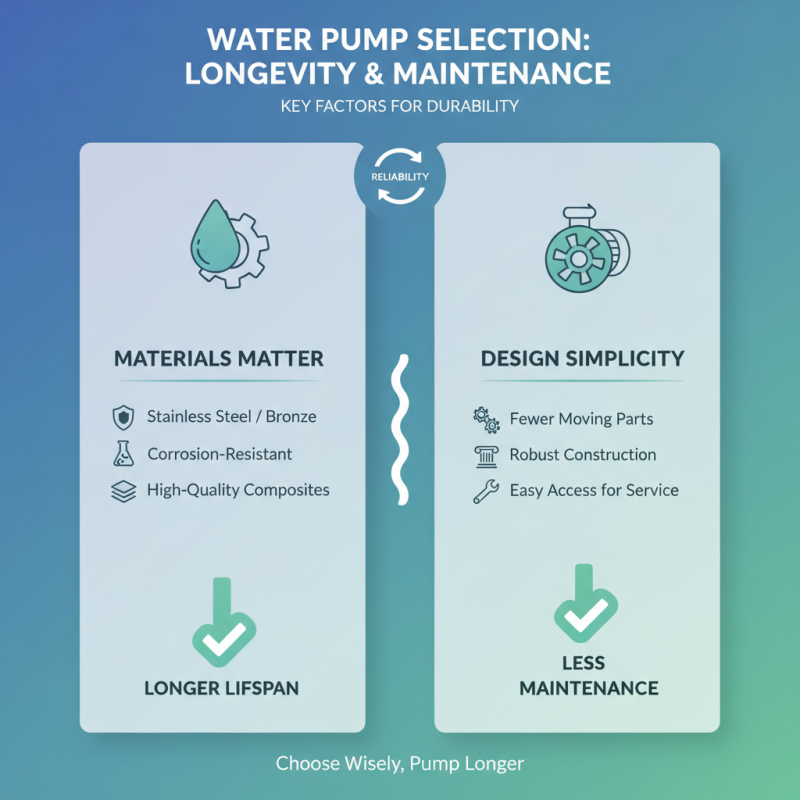

When selecting a water pump technology, the longevity and maintenance requirements of different options play pivotal roles in the decision-making process. One of the first steps in assessing any water pump is to consider the materials used in its construction. Pumps made from high-quality, corrosion-resistant materials tend to last longer and require less frequent maintenance. Additionally, the design of the pump itself can impact its longevity; simpler, more robust designs often have fewer points of failure and can withstand wear and tear better than complex setups.

Maintenance is another crucial factor to weigh during your selection process. Some pumps offer advanced features such as self-cleaning capabilities or low-maintenance designs, which can drastically reduce the time and effort needed for upkeep. Understanding the manufacturer's maintenance recommendations, including the frequency and type of servicing required, can help you anticipate long-term costs and efforts associated with various pump options. Moreover, selecting a pump with accessible parts and clear service protocols can significantly ease the burden of maintenance, ensuring that the pump remains operational for an extended period without unexpected downtimes.

When selecting the right water pump technology for your needs, budgeting and cost considerations play a crucial role. According to a report from the Water Environment Federation, the initial capital costs associated with purchasing a water pump can vary significantly based on the type and specifications of the pump. For instance, centrifugal pumps typically range from $1,000 to $5,000, while submersible pumps can cost anywhere from $1,500 to over $10,000, depending on their capacity and features. Additionally, operational costs, which include electricity consumption and maintenance, can account for up to 70% of the total lifetime cost of the pump, making it essential to factor these into your budgeting.

Moreover, a study by the American Society of Agricultural and Biological Engineers suggests that energy efficiency should be a primary consideration when selecting a water pump. A more energy-efficient model may have a higher upfront cost but can lead to significant savings over time. The report indicates that up to 30% savings in energy costs can be achieved with high-efficiency pumps compared to standard models. Therefore, understanding the total cost of ownership—combining purchase price, installation, energy consumption, and maintenance—is vital for making an informed decision that aligns with your budgetary constraints while ensuring optimal performance.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.