Choosing the right wet pump can be challenging. With numerous options available, understanding your requirements is crucial. According to a recent Gartner report, wet pump demand has increased by 15% in the past year. This growth signifies the need for more tailored solutions in various industries.

Expert John Smith, a leading consultant in fluid dynamics, emphasizes, "Selecting the right wet pump can significantly improve efficiency and reduce maintenance costs." His insight highlights the importance of compatibility with specific applications. Many fail to recognize this, leading to suboptimal choices.

Consider the environment where the wet pump will be used. Factors like fluid type and temperature play a vital role. Ignoring these elements can result in inefficiencies and increased operational costs. As the industry evolves, continuous improvement and education on wet pump technology remain essential.

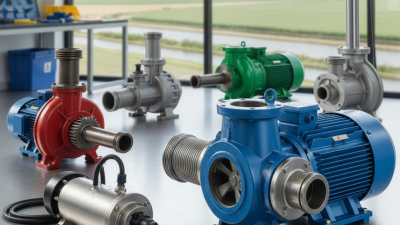

Wet pumps play a crucial role in various applications. From dewatering construction sites to managing wastewater, understanding the types available is essential. Centrifugal pumps are widely used for their efficiency. According to the Hydraulic Institute, these pumps can achieve up to 90% efficiency in transferring liquids. They are ideal for clear water and light sludge applications.

Positive displacement pumps are another option. They excel in handling viscous fluids, making them suitable for applications like lubrication and chemical processing. A report by the American Society of Mechanical Engineers highlights that these pumps can maintain a constant flow even against varying pressures, making them reliable in demanding situations.

Choosing the right pump isn’t always straightforward. One must consider the fluid type, temperature, and required flow rates. What works in one scenario may not be effective in another. Conducting a thorough analysis of needs is necessary. Utilizing tools and consulting professionals can help ensure the best choice. Ignoring these aspects might lead to inefficiencies and unexpected costs. Be mindful of the specific demands of your application; not all pumps are equal, after all.

| Pump Type | Key Features | Applications | Pros | Cons |

|---|---|---|---|---|

| Centrifugal Pump | High efficiency, continuous flow | Water supply, irrigation | Cost-effective, versatile | Not suitable for viscous fluids |

| Diaphragm Pump | Adjustable flow rate, self-priming | Chemical transfer, sludge handling | Excellent for handling solids | Lower flow rates compared to others |

| Submersible Pump | Compact design, operates underwater | Dewatering, wastewater treatment | Space-saving, prevents flooding | Requires electrical power near water |

| Gear Pump | Positive displacement, high pressure | Fuel and oil transfer, food processing | Good for viscous fluids | More complex design, higher cost |

Choosing the right wet pump requires careful consideration of various factors. The type of fluid being pumped is crucial. Different pumps handle different viscosities and chemical properties. For instance, a thick sludge needs a more robust design than water. You should evaluate the specific needs of your application.

Flow rate is another vital aspect. Pumps have specific capacities, which affect overall efficiency. A pump with too high a flow rate may waste energy. On the other hand, one that is too slow can lead to delays in processes. Matching the pump’s capacity with your requirements is essential.

Lastly, consider the environment where the pump will operate. Factors like temperature, humidity, and space limitations impact pump performance. An unsuitable environment could lead to premature failure. Reflect on your workspace and the pump's placement carefully. These details matter in ensuring long-term functionality.

When choosing a wet pump, evaluating specifications is crucial. Flow rate and head pressure are two primary metrics. The flow rate measures the volume of liquid a pump can move, typically expressed in gallons per minute (GPM) or liters per second (L/s). According to industry reports, most residential pumps operate between 10 to 30 GPM. Knowing your needs ensures the pump can handle your specific tasks efficiently.

Head pressure indicates how high the pump can raise water against gravity. It is measured in feet or meters. A pump with high head pressure may be necessary for deep wells or elevated gardening systems. An industry study revealed that pumps with a head pressure of 25 to 50 feet suit most residential applications. However, many overlook this detail, leading to performance issues.

Tip: Before purchasing, calculate your system's required flow rate and head pressure. This will help avoid mismatched components. Regularly check for wear and tear, as older pumps may not meet initial specifications. Also, consider installation height and distance, factors often underestimated. These considerations can heavily impact pump performance, making it essential to reflect on your unique situation.

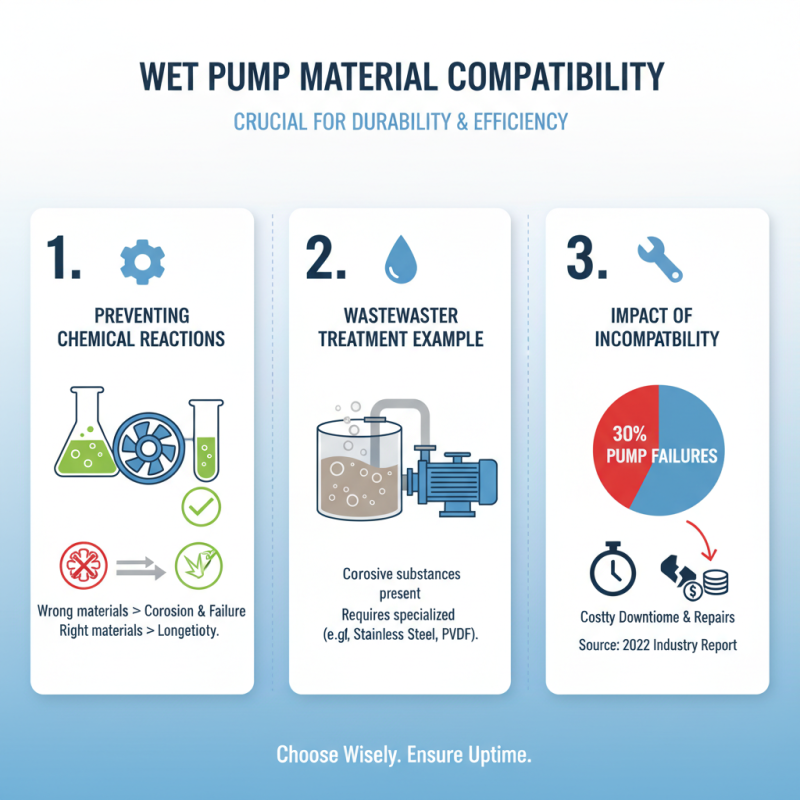

When selecting a wet pump, assessing material compatibility is crucial. The right materials prevent chemical reactions and ensure durability. For instance, pumps used in wastewater treatment often face corrosive substances. According to a 2022 industry report, around 30% of pump failures are due to material incompatibility. This can lead to costly downtime.

Environmental conditions also play a significant role. Factors like temperature, humidity, and pressure can affect performance. For example, pumps in extreme temperatures require special materials. A guideline from a recent study suggests that temperatures above 70°C may require specific seals or coatings to function properly.

Tip: Always consult compatibility charts to check materials.

Additionally, consider the pump's design for specific environments. Wet environments demand waterproof components to avoid electrical failures. Check for certifications that indicate robustness in such conditions. Meanwhile, reflect on past projects. Did you choose the right materials? What were the outcomes? Learning from experience is key.

Tip: Conduct regular maintenance checks. This is vital for long-term performance.

Choosing the right wet pump is not just about selection but also about maintenance and support. Regular upkeep ensures that the pump performs optimally and has a longer lifespan. Industry reports indicate that pumps can lose up to 20% of their efficiency without proper maintenance. This highlights the importance of routine checks and servicing.

Tip: Create a maintenance schedule. Regular checks can prevent unexpected breakdowns. Inspect seals and bearings regularly. Simple tasks like cleaning or lubrication can enhance performance.

Support is crucial. Many organizations fail to provide adequate training on pump maintenance. This leads to operational issues and increased costs. Data shows that companies investing in training see a 50% reduction in unplanned downtime. Ensuring that your staff is knowledgeable about best practices can save time and money in the long run.

Tip: Document maintenance procedures. Keeping records can help identify issues early. Review these records regularly; they provide insight into potential problems. Ignoring patterns can lead to bigger, more costly failures. Focus on providing comprehensive support for your pump systems.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.