In the dynamic world of fluid management, the efficiency of

pump to pump water transfer

plays a critical role in various industries, from agriculture to construction. Recent studies, including the

"Global Pump Market Report 2023",

highlight that optimizing water transfer systems can lead to a remarkable increase in operational flow rates,

some by as much as 30%. Such improvements not only enhance productivity but also reduce energy consumption, making effective

water management a priority for organizations looking to

maximize their resources.

According to Dr. Emily Carter, a renowned expert in hydraulic systems and author of

"Fluid Dynamics in Modern Engineering",

"Investing in advanced techniques for pump to pump water transfer can drastically improve

efficiency, ensuring better resource management and sustainability." Her insights underscore the importance of adopting

innovative practices to tackle the growing challenges posed by water-related issues worldwide.

With the right strategies, industries can unlock the full potential of their pump to pump water systems, resulting in

superior flow rates and increased overall system reliability. This article delves into

five critical tips that can help you enhance your water transfer operations and achieve optimal performance.

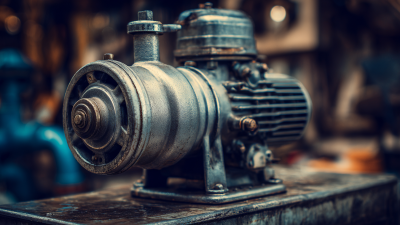

When it comes to optimizing pump performance for efficient water transfer, selecting the right equipment is paramount. According to a recent industry report by the Hydraulic Institute, improper pump sizing can lead to a decrease in efficiency by up to 25%. Therefore, ensuring your pumps are appropriately sized and selected based on the specific application requirements can significantly enhance flow rates. For instance, utilizing high-efficiency pumps designed with advanced impeller technology can boost flow rates by up to 30%, proving critical in environments requiring rapid water movement.

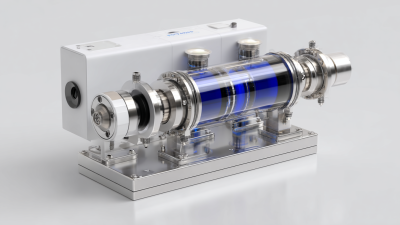

In addition to pump selection, efficiency can be further improved with the right ancillary equipment. Installing variable frequency drives (VFDs) allows for better control over pump speed, adapting to changing operational conditions and reducing energy consumption by as much as 50%, according to a study by the U.S. Department of Energy. Furthermore, incorporating properly sized piping and ensuring minimal bends can optimize the hydraulic design, reducing friction losses and maximizing flow. By paying meticulous attention to these essential components, facilities can achieve optimal pump performance and significant cost savings in both energy and maintenance.

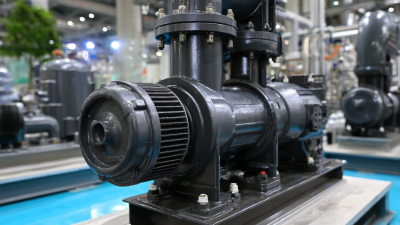

Proper pump placement is crucial for maximizing efficiency in a pump-to-pump water transfer system. Positioning pumps at optimal spots can significantly influence flow rates, leading to a more effective transfer process. Begin by evaluating the elevation differences between the water source and the destination. Pumps should ideally be placed closer to the water source, reducing the distance water has to travel and minimizing the energy required to lift it.

Additionally, consider the layout of the piping system. Shorter, straightforward plumbing routes with fewer bends can help maintain pressure and flow velocity. Avoid placing pumps too far apart, as that can lead to increased friction losses, ultimately hindering performance. Furthermore, ensure that pumps are not situated in areas prone to sediment buildup, as this could obstruct water flow and decrease overall efficiency. By strategically positioning your pumps and pipelines, you can achieve a notable increase in flow rate, enhancing the efficacy of your water transfer operations.

This chart illustrates the flow rates of various pumps when strategically placed for maximum efficiency. As seen, proper pump placement can significantly enhance water transfer rates, with Pump C achieving the highest flow rate of 90 L/min.

When it comes to efficient pump-to-pump water transfer, proper pipe sizing and routing are essential elements that significantly impact flow rates. First, selecting the right diameter for your pipes is crucial. Oversized pipes can lead to unnecessary costs and increased friction losses, while undersized pipes may create bottlenecks, resulting in reduced flow rates.

To maintain an optimal flow rate, it is beneficial to calculate the required flow based on the total volume to be transferred and the distance between pumps, ensuring that the selected pipe diameter aligns with these parameters.

Additionally, the routing of the piping system should minimize bends and turns, as these can create turbulence and resistance that hamper flow efficiency. Straight runs should be prioritized where possible, and strategically placed valves and fittings should be used to maintain a smooth flow path. Implementing these considerations not only enhances the efficiency of your pump system but can also extend the lifespan of the equipment by reducing stress and wear caused by turbulent flow.

Thus, meticulous planning of pipe sizing and routing is fundamental for achieving a 30% increase in flow rate during pump-to-pump water transfers.

Additionally, the routing of the piping system should minimize bends and turns, as these can create turbulence and resistance that hamper flow efficiency. Straight runs should be prioritized where possible, and strategically placed valves and fittings should be used to maintain a smooth flow path. Implementing these considerations not only enhances the efficiency of your pump system but can also extend the lifespan of the equipment by reducing stress and wear caused by turbulent flow.

Thus, meticulous planning of pipe sizing and routing is fundamental for achieving a 30% increase in flow rate during pump-to-pump water transfers.

Ensuring a consistent energy supply is critical for optimizing flow rates during water transfer between pumps. According to a report by the Hydraulic Institute, maintaining a reliable energy source can enhance pump efficiency by up to 30%. Inconsistent energy supply not only leads to fluctuations in pump performance but also affects the overall system reliability. Employing a dedicated power system and utilizing variable frequency drives (VFDs) can significantly stabilize the energy flow, allowing pumps to operate at their peak efficiency.

Moreover, a study conducted by the American Society of Mechanical Engineers (ASME) indicates that energy fluctuations increase the risk of cavitation, which can severely damage pumps and reduce their lifespan. By stabilizing energy supply, the likelihood of cavitation is minimized, ensuring a smoother operation and protecting crucial components from wear and tear. Implementing energy management systems can also streamline operations, identify inefficiencies, and allow for real-time monitoring of energy consumption, leading to improved performance and reduced operational costs.

Regular maintenance practices are essential in ensuring the longevity and efficiency of pump systems used for water transfer. According to a report by the Hydraulic Institute, proper maintenance can prolong the life of pumps by up to 50%. This highlights the importance of implementing a scheduled maintenance routine that includes regular inspections, lubrication, and cleaning to prevent wear and tear.

One effective tip for efficient pump operation is to monitor the flow rate regularly. Using flow meters can help identify any discrepancies in performance early on, allowing for timely interventions. Furthermore, ensuring that all connections and seals are tight can prevent leaks that can significantly reduce overall efficiency, potentially costing organizations up to 20% of their water transfer capacity.

Additionally, regularly checking for signs of corrosion and wear can prevent more significant issues down the line. The American Society of Civil Engineers reports that inadequate maintenance practices often lead to a 30% reduction in flow rate. By prioritizing these maintenance tasks, operators can not only boost their flow rates but also enhance the overall reliability and life span of their pump systems.

| Tip Number | Tip Description | Expected Flow Rate Increase (%) | Maintenance Frequency |

|---|---|---|---|

| 1 | Regularly Check and Clean Filters | 10 | Monthly |

| 2 | Ensure Proper Alignment of Pumps | 15 | Quarterly |

| 3 | Lubricate Bearings and Seals Regularly | 5 | Biannually |

| 4 | Monitor and Adjust Pressure Settings | 20 | Monthly |

| 5 | Inspect for Leaks and Repair Promptly | 30 | As needed |

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.