Pumping water efficiently and effectively is essential in various applications. Whether for agriculture, irrigation, or household use, the method of pump to pump water plays a crucial role. Choosing the right pump can impact both energy consumption and water output.

Understanding how to pump to pump water efficiently involves several factors. The size and type of pumps, as well as their placement, significantly influence performance. Proper maintenance is often overlooked but vital for longevity and efficiency. Many users fail to regularly check their systems, leading to decreased output.

Improper setups can lead to wasted energy and water. It’s essential to evaluate existing equipment and explore enhancements. Mistakes can teach valuable lessons about efficiency. The goal should always be not just to pump to pump water but to do so in a way that maximizes resources.

Understanding water pumping systems is vital for efficiency. A good pump system can save energy and time. However, even the best systems can have flaws. For instance, incorrect sizing can lead to inefficiency. An oversized pump may waste energy. Conversely, an undersized pump may struggle.

Regular maintenance is crucial. Check for clogs and leaks. Dirty filters can impede flow, decreasing overall performance. Additionally, ensure that the pump is properly aligned. Misalignment can cause damage over time.

Tips for operating pumps effectively include monitoring pressure levels. Too much pressure can lead to failures. Use a timer for automatic operations. This prevents overuse. Lastly, consider the energy source. Alternative energy can be more cost-effective in the long run.

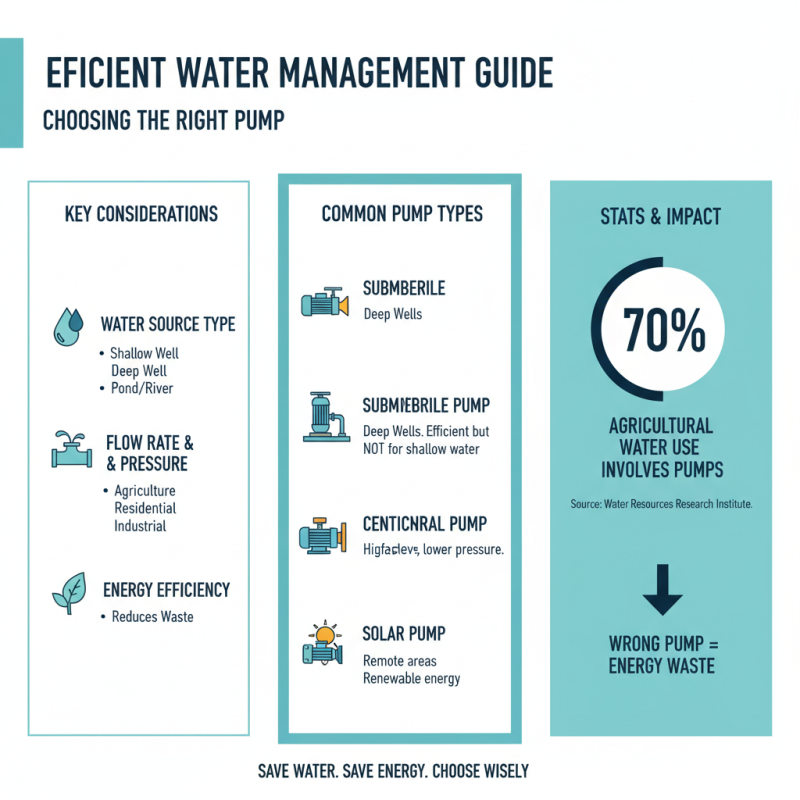

Choosing the right type of pump is crucial for efficient water management. Various pumps serve different needs. According to the Water Resources Research Institute, around 70% of agricultural water use involves pumps. Selecting the wrong pump can lead to energy wastage. For instance, submersible pumps are effective but may not be ideal for shallow water sources. Understanding your specific requirements is essential.

Consider flow rate and pressure. The Hydraulic Institute recommends calculating the necessary flow rate to match your usage. If the pump does not meet these specifications, you may face inefficiencies. Centrifugal pumps are popular for their energy efficiency. However, if misapplied, they can result in over-pumping or under-pumping situations.

Pay attention to the pump's material and design. Some pumps are not suited for certain fluids. Incompatible materials can wear out quickly. It's advisable to consult industry data before making a choice. In many cases, users overlook maintenance needs, which can affect performance. Proper selection and care are keys to maximizing efficiency.

When considering pump efficiency and effectiveness, several key factors come into play. The design of the pump significantly impacts its performance. For instance, a well-designed impeller can optimize water flow. A poorly designed pump may cause cavitation, leading to damage. Regular maintenance is crucial. Clogged filters can reduce efficiency. Cleaning and checking these parts helps maintain optimal function.

Next, the operating conditions are vital. The temperature and viscosity of the fluid influence how easily water moves through the system. In cold weather, viscosity increases. This can hinder efficiency. Adjusting the speed and power of the pump may be necessary. Additionally, understanding the pump's duty cycle is important. Overworking a pump can lead to overheating and failure.

Lastly, the layout of the piping system matters too. Long or twisted pipes can create additional friction. This can reduce overall performance. It’s essential to assess the entire system. Human errors in installation may also occur. Take time to evaluate these details. Being mindful of these factors is crucial for maximizing pump effectiveness.

| Factor | Description | Impact on Efficiency (%) | Recommended Range |

|---|---|---|---|

| Pump Type | Different pump types (centrifugal, positive displacement) have varying efficiencies. | 10-20% | Depends on application |

| Fluid Characteristics | Viscosity, density, and temperature of the fluid can affect pump performance. | 5-15% | Target specifications |

| Pipe Diameter | Larger diameters reduce friction and improve flow rates. | 5-12% | Optimize size for system |

| System Design | Effective layout minimizes bends and friction losses. | 10-25% | Simplified pathways |

| Maintenance | Regular upkeep ensures optimal pump performance and longevity. | 10-30% | Scheduled intervals |

Installing and maintaining water pumps requires attention to detail. Proper installation sets the foundation for efficiency. A study by the Water Research Foundation indicates that up to 30% of energy is wasted due to incorrect pump sizing. Use the right pump for your needs. Oversizing pumps can lead to excessive wear and higher energy costs. Ensure your system matches the specifications.

Regular maintenance is crucial. A survey shows that 40% of pump failures are due to lack of preventative care. Check seals, bearings, and impellers routinely. Small leaks can lead to significant losses over time. Keeping the pump clean helps it operate efficiently. Vibration monitoring is also essential. It can indicate potential issues before they become serious, allowing for timely interventions.

Be mindful of the environment around your pumps. Poor atmospheric conditions can impact performance. Water quality matters too; sediments can cause blockages or damage. Implementing a filtration system could enhance durability. Reflect on the system's overall design. Sometimes, adjustments can lead to improved efficiency and cost savings. Regular evaluations lead to better practices.

This chart illustrates the efficiency of various types of water pumps, showcasing the difference in performance. The Submersible Pump leads with the highest efficiency at 85%, followed by the Screw Pump at 80%. Understanding these differences can aid in selecting the right pump for your needs.

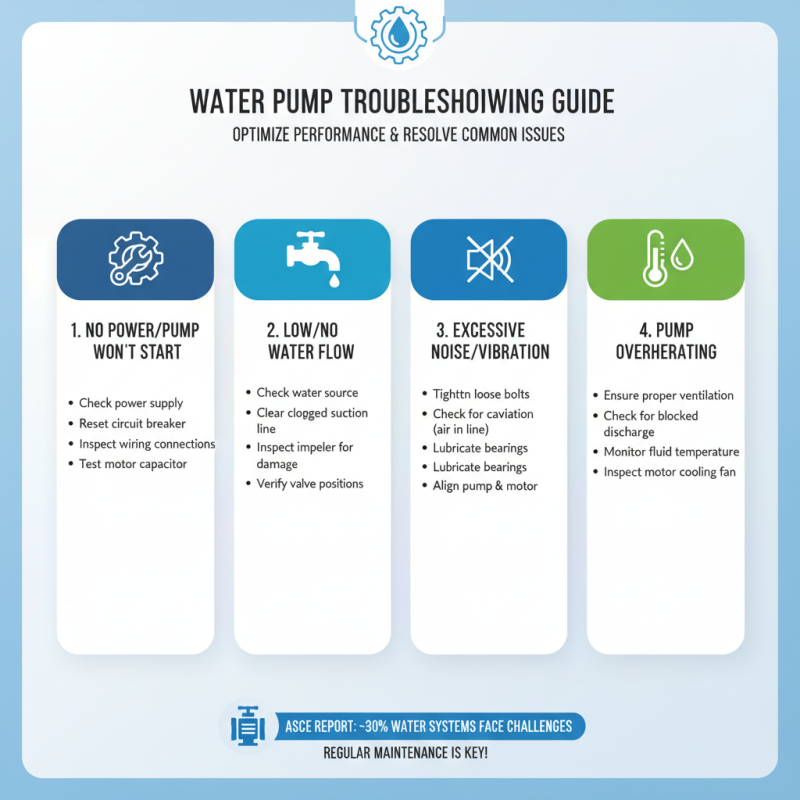

Water pumps are essential in various applications. However, issues can arise that affect their performance. According to a report by the American Society of Civil Engineers, nearly 30% of water systems face operational challenges. Understanding troubleshooting techniques can help ensure optimal performance of your water pump.

Common issues include air locks, clogs, and unusual noises. An air lock may occur when air enters the pump system, leading to reduced efficiency. Clearing the air using the venting procedures can resolve the issue. Clogs often happen in filters and pipes. Regular maintenance is crucial. It is recommended to check filters every three months for blockages. Noise issues can indicate mechanical problems, such as worn bearings or misaligned parts. Ignoring these sounds may lead to costly repairs.

Data from the National Water Well Association shows that improper maintenance can reduce pump efficiency by up to 50%. Regular inspections and timely repairs can prevent these significant losses. Inadequate attention to operational signs may result in equipment failures. Investing in a monitoring system can help detect anomalies early. This approach minimizes downtime and extends the life of your pumps. Efficient water pumping is not just about installation but also about consistent care.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.