Choosing the right water pump equipment is crucial for ensuring efficiency and reliability in various applications, ranging from agricultural irrigation to industrial operations. According to the Global Water Pump Market report, the demand for water pump equipment is projected to reach $70 billion by 2026, driven by increasing water scarcity issues and the need for sustainable water management solutions. Moreover, a study by Research and Markets indicates that advancements in pump technology are enhancing the efficiency and longevity of these systems, making informed choices more critical than ever. With a myriad of options available, understanding the specific needs based on application, flow rate, and power source becomes essential. This guide presents seven essential tips to help you navigate the complexities of selecting the ideal water pump equipment tailored to your needs.

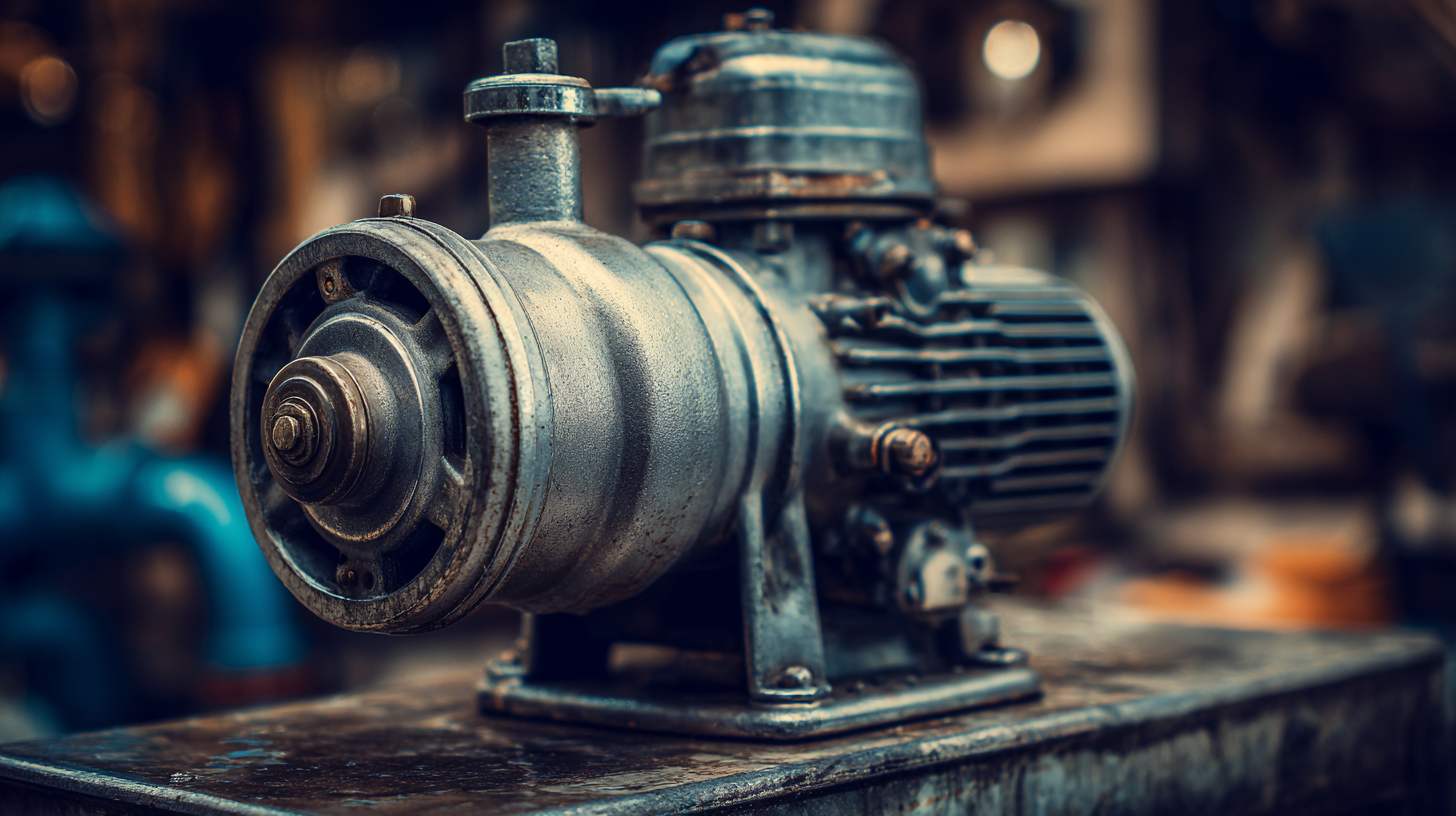

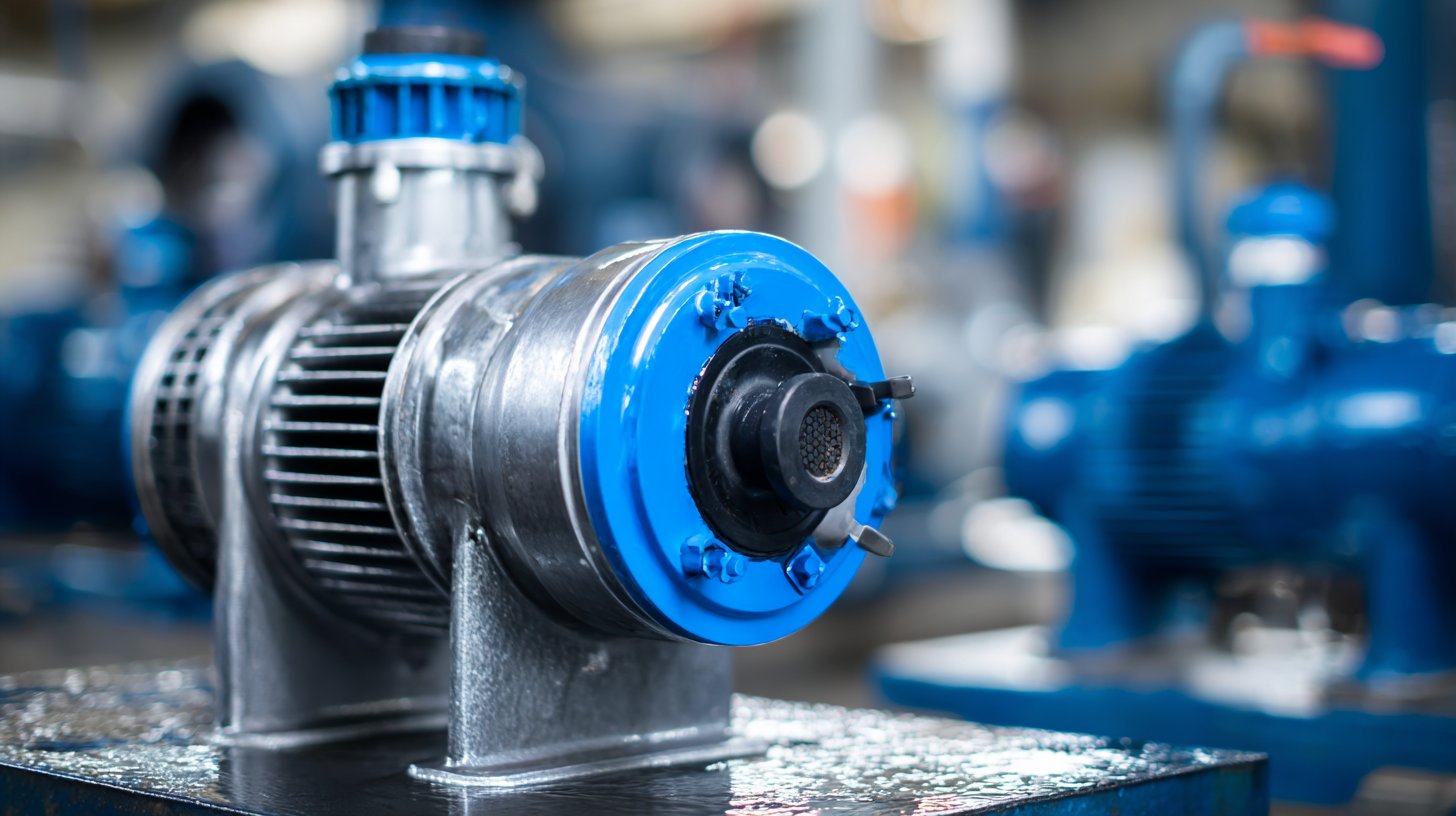

When selecting the right water pump, it's crucial to understand the various types available on the market, each designed for specific applications. Submersible pumps are ideal for draining basements or flooded areas, as they operate underwater and can handle debris-laden water efficiently. On the other hand, centrifugal pumps are predominant in agricultural and irrigation settings, utilizing a rotating impeller to create suction and move large volumes of water.

Another type worth considering is the diaphragm pump, which is excellent for transferring viscous fluids or chemicals due to its ability to manage varying flow rates without changing the pressure. Additionally, solar-powered pumps have gained popularity for their eco-friendliness and independence from electrical sources, making them suitable for remote applications. Understanding these variations will help you better assess your needs and choose the pump that is most efficient for your specific situation.

| Pump Type | Best For | Flow Rate (GPM) | Max Head (ft) | Power Source | Tips |

|---|---|---|---|---|---|

| Submersible Pump | Basements & Wells | 10-100 | 15-30 | Electric | Ensure proper sealing to avoid electrical hazards. |

| Centrifugal Pump | Irrigation & Drainage | 50-400 | 10-50 | Electric, Diesel | Choose a pump size based on your flow requirements. |

| Diaphragm Pump | Chemical Transfer | 5-50 | 20-40 | Electric, Pneumatic | Check compatibility with the fluid being pumped. |

| Gear Pump | Viscous Liquids | 5-100 | 30-60 | Electric | Ideal for transferring oils and other thick fluids. |

| Trash Pump | Construction & Flood Cleanup | 10-300 | 25-45 | Gas, Electric | Look for a pump that can handle large solids. |

When selecting the right water pump equipment, understanding key specifications is crucial to ensure optimal performance for your specific needs. One of the primary considerations is the flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s). This indicates how much water the pump can move within a specific timeframe, and it's essential to match this rate with your requirements to prevent under- or over-pumping.

Another important specification is the total dynamic head (TDH), which measures the height the pump can raise water, accounting for friction losses in the system. It’s essential to evaluate the specific height the water needs to be lifted and any potential resistance from pipes or fittings. Additionally, consider the power source compatibility, whether it’s electric, gas, or solar, to ensure the pump will operate efficiently in your intended environment. Finally, don't overlook the material composition of the pump, which impacts durability and resistance to corrosion, especially in harsh or chemically aggressive settings.

When selecting water pump equipment, understanding your water flow requirements is crucial for optimal performance. According to the Hydraulic Institute, a leading authority in pump standards, the efficiency of a pump can decrease significantly if it doesn't match the required flow rates. For instance, operating a pump at flows below 50% of its rated capacity can lead to issues such as cavitation and excessive wear, ultimately reducing its lifespan and operational efficiency.

To accurately assess your water flow needs, consider factors such as the distance water needs to travel, the elevation change, and specific application requirements. A report from the American Society of Civil Engineers indicates that improper evaluation of these factors can result in up to 30% energy inefficiency. Additionally, engaging in flow tests can provide precise data, helping to ensure that the chosen pump will meet both current and future needs without risking performance or increasing operating costs. Tailoring your selection to these requirements not only enhances performance but also optimizes energy consumption, making a more sustainable and cost-effective choice.

When selecting water pump equipment, evaluating energy efficiency and cost-effectiveness is crucial. Energy-efficient pumps can significantly reduce operational costs over time. Look for models with high efficiency ratings, which are designed to minimize energy consumption while delivering optimal performance. Additionally, considering variable frequency drives (VFDs) can enhance efficiency by adjusting the pump's speed based on demand, leading to further energy savings.

Cost-effectiveness goes beyond the initial purchase price. It's essential to assess the long-term operating costs, including maintenance, energy use, and potential downtime. Analyzing lifecycle costs helps in making informed decisions that balance upfront expenses with future savings. Additionally, check for warranties and service agreements that may provide further financial protection and reliability. By prioritizing these elements, you can choose a water pump that not only meets your immediate needs but also supports sustainable and economical operation in the long run.

Proper maintenance is crucial for extending the lifespan of your water pump equipment. Regular inspection is the first step in ensuring that your pump operates efficiently. Check for any signs of wear and tear, such as leaks or unusual noises, which can indicate underlying issues. Additionally, keep the inlet and outlet free from obstructions to maintain optimal flow and pressure.

Another important aspect of maintenance is to routinely change the oil and filters as specified by the manufacturer. Clean fluids are essential for proper lubrication and cooling, preventing overheating and wear on components. Additionally, consider seasonal checks, especially before periods of high usage. Draining and cleaning the pump before winter can prevent freezing and damage, ensuring it’s ready for the next season.

Implementing these practices will help you maximize your water pump's performance and longevity.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.