Choosing the right gear pumps for your applications can significantly impact both performance and efficiency in various industries. Gear pumps are widely recognized for their reliability and ability to handle high viscosity fluids, making them essential components in sectors such as oil and gas, chemicals, and food processing. According to the latest market research report by Grand View Research, the global gear pump market size is expected to reach USD 5.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.6%. This growth is driven by the increasing demand for advanced pumping solutions in manufacturing processes.

In the context of selecting gear pumps, understanding the specific requirements of your application is critical. Factors such as flow rate, pressure requirements, and fluid characteristics must be carefully considered to ensure optimal performance. Additionally, as industries shift towards more sustainable practices, the need for energy-efficient gear pumps that minimize operational costs is becoming increasingly important. A report by MarketsandMarkets indicates that energy-efficient pumps can reduce energy consumption by up to 30%, emphasizing the need for manufacturers and engineers to make informed choices when selecting gear pumps. This article will outline ten essential tips to guide you in choosing the right gear pumps to meet your operational needs effectively.

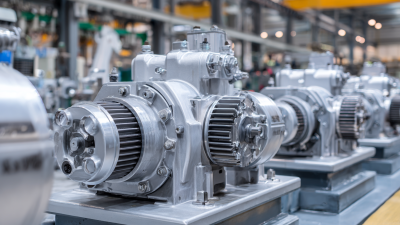

When selecting the right gear pump for your applications, it's crucial to understand the different types of gear pumps available and their specific applications. Gear pumps are essential in various industries, including hydraulics, oil and gas, and chemical processing, where precise flow control and durability are paramount. The two main types of gear pumps—external and internal—offer distinct advantages depending on the application. External gear pumps are ideal for low-viscosity fluids and provide a consistent flow, whereas internal gear pumps handle higher viscosity fluids and are better suited for applications requiring high pressure.

According to a recent market report, the outdoor gear equipment market, which encompasses various gear pumps, is projected to grow significantly, reaching $111.68 billion by 2035, up from a valuation of $61.7 billion in 2025. This growth reflects an increasing demand across sectors, driven by advancements in technology and the need for more efficient fluid handling solutions. As industries evolve, understanding the core functionalities and benefits of various gear pump types will be essential for optimizing operational efficiency and meeting market demands.

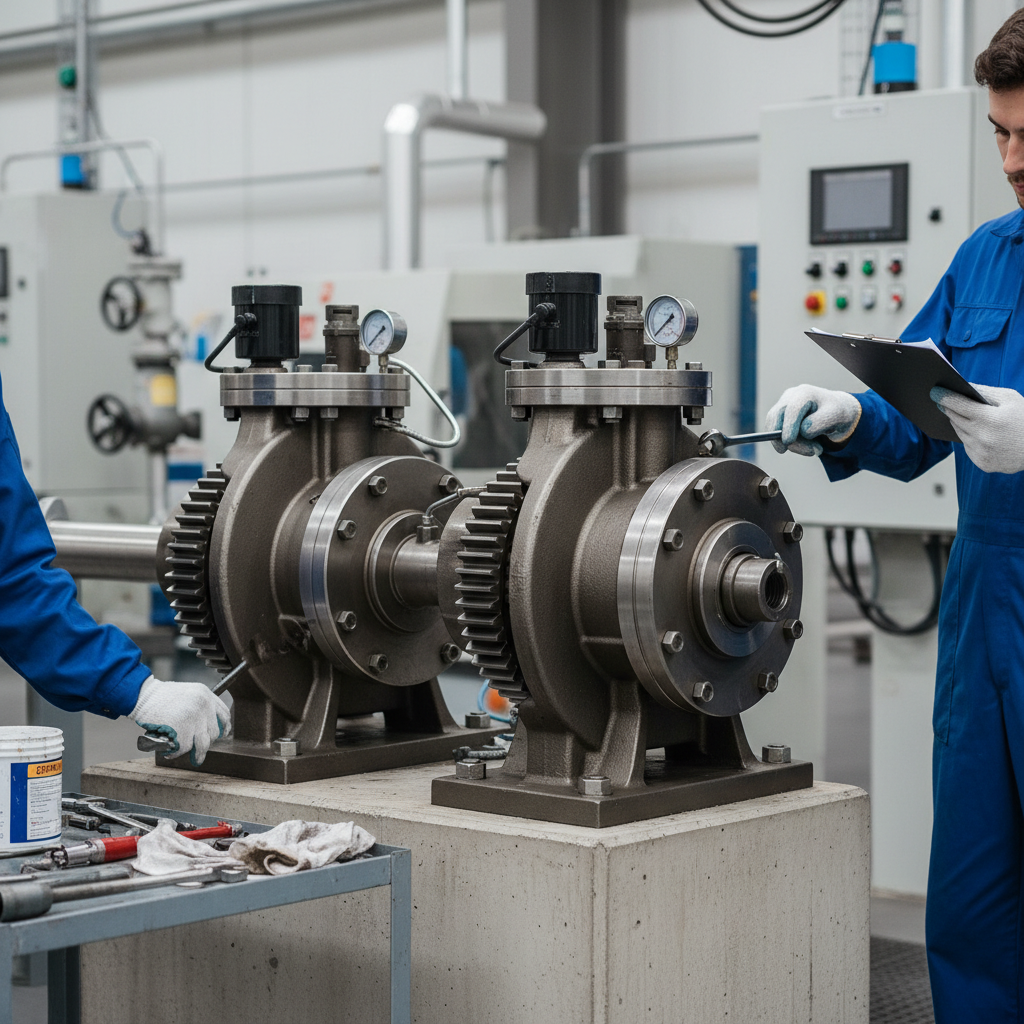

When selecting gear pumps for your applications, it is crucial to consider several key factors that directly influence performance and efficiency. First, the type of fluid being pumped plays a significant role. Different fluids, whether they are viscous, corrosive, or containing solid particles, require specific pump designs to ensure optimal operation. For instance, higher viscosity fluids could necessitate pumps with larger clearances to reduce wear and maintain efficiency.

Another critical factor is the operating conditions, such as pressure and temperature. Understanding the maximum and minimum operational parameters is essential for ensuring that the gear pump can perform effectively without risking damage. Additionally, evaluating the required flow rate and head pressure is vital, as these metrics will inform your choice of pump size and type. Lastly, consider the ease of maintenance and availability of replacement parts, as these factors can greatly affect the total cost of ownership and long-term reliability of the equipment.

This bar chart illustrates the importance of various factors to consider when selecting gear pumps for applications. The effectiveness of gear pumps is heavily influenced by these key attributes, which vary in significance based on the specific requirements of the application.

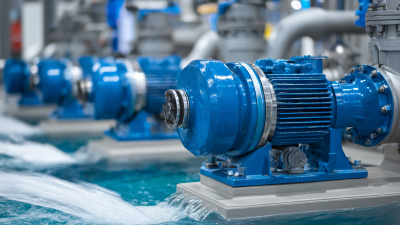

When selecting gear pumps, one of the most critical aspects to evaluate is the flow rate and pressure requirements of your specific application. Gear pumps are favored in various industrial sectors due to their ability to handle a wide range of fluids, including those with high viscosities. For instance, high-viscosity gear pumps play a crucial role in transporting polymer media, where maintaining a steady flow rate is essential to avoid system fluctuations. Research indicates that the performance of these pumps significantly varies with factors such as viscosity and operational speed, necessitating careful analysis during the selection process.

Additionally, the integration of advanced technologies like Computational Fluid Dynamics (CFD) allows for accurate modeling of gear pump performance under varied operational conditions. A recent study highlighting the vibroacoustic field of external gear pumps demonstrates the importance of considering structural dynamics, which can influence pressure stability and flow efficiency. Understanding the interplay between flow rates, operating pressure, and mechanical design is vital, especially in applications like ventricular assist devices, where maintaining optimal fluid dynamics is crucial for device efficacy and longevity. Adopting a detailed evaluation approach will lead to better-suited gear pumps that enhance application performance and reliability.

When selecting gear pumps for specific applications, material compatibility is a crucial factor that significantly influences pump longevity. Gear pumps are often exposed to various fluids, including corrosive chemicals, abrasive materials, and high-temperature substances. Therefore, understanding the chemical resistance of the pump's materials, such as the casing, gears, and seals, is essential to prevent premature wear or failure. For example, using a pump with a stainless steel casing might be ideal for handling acidic solutions, while specialized polymers may be better suited for viscous or abrasive fluids.

Moreover, the interaction between the pump materials and the pumped fluid can lead to various physical and chemical reactions that affect performance. It's important to consider not only the compatibility with the process fluid but also the operating environment, such as temperature fluctuations and exposure to UV light. Choosing the appropriate materials based on these conditions can extend the lifespan of the gear pump and enhance its reliability. Thus, proper material selection should be a foundational step in the decision-making process, ensuring that the gear pump operates efficiently and maintains its integrity over time.

| Tip | Material Compatibility | Impact on Longevity | Recommended Materials |

|---|---|---|---|

| 1. Understand the Fluid Characteristics | Compatibility with chemicals, temperature, and viscosity | Improves lifespan by reducing wear | Stainless Steel, PTFE |

| 2. Consider Operating Temperature | Material resistance to heat and cold | Prevents thermal expansion issues | Aluminum, Cast Iron |

| 3. Assess Pressure Requirements | Material strength under pressure | Minimizes the risk of ruptures | Bronze, Ductile Iron |

| 4. Evaluate Abrasiveness of the Fluid | Resistance to wear from solid particles | Enhances durability and pump life | Hardened Steel, Composite Materials |

| 5. Determine Environmental Factors | Corrosion resistance for external conditions | Prevents premature deterioration | Epoxy Coatings, Stainless Steel |

| 6. Analyze Pump Design and Orientation | Impact of gravity on material choice | Ensures proper functioning and longevity | Sanitary Designs, Vertical vs. Horizontal |

| 7. Review Maintenance Requirements | Impact of materials on ease of upkeep | Longer intervals between service | Sealed Systems, Low-Friction Materials |

| 8. Investigate Noise Levels | Material impact on vibration and sound | Quiets operation, reduces wear | Rubber Mounts, Composite Casings |

| 9. Consider Installation Space | Size and geometry based on material | Facilitates effective cooling and access | Compact Models, Custom Designs |

| 10. Seek Expert Advice | Insights on compatible materials and designs | Optimizes pump selection for longevity | Consulting with Engineers |

When selecting the right gear pumps for your applications, maintenance and support play a crucial role in ensuring optimal performance. Regular maintenance schedules not only extend the lifespan of gear pumps but also enhance their efficiency. According to a report by the Hydraulic Institute, proper maintenance can reduce the likelihood of pump failure by up to 70%. Establishing a routine that includes checking for leaks, ensuring adequate lubrication, and monitoring performance metrics can lead to significant cost savings over time.

Tip: Select gear pumps that come with comprehensive support from manufacturers. This includes access to technical expertise and readily available spare parts. Research indicates that organizations utilizing gear pump systems with strong manufacturer support experience a 30% higher operational efficiency. Investing in gear pumps designed for easy maintenance can simplify these processes, further reducing downtime and repair costs.

Additionally, consider the training of personnel involved in maintenance. Equipping your team with the right skills can make a significant difference in how effectively repairs and preventive measures are implemented. Studies show that companies that prioritize operator training see improved performance and reduced incidents of pump failures by nearly 40%. Ultimately, prioritizing maintenance and support will not only enhance the performance of your gear pumps but also contribute to the overall efficiency of your operations.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.