In today's environmentally conscious society, the efficient use of resources is more crucial than ever, particularly when it comes to water management. Choosing the right equipment to optimize water usage can lead to significant cost savings and sustainability. As John Smith, a renowned expert in water pump technology, aptly states, “Selecting the right water pump for water applications not only maximizes efficiency but also minimizes energy consumption and operational costs.” This assertion highlights the importance of making informed decisions when it comes to water pumps.

Understanding the key factors in selecting a water pump for water applications—such as flow rate, power source, and specific use case—can greatly enhance water efficiency and reduce expenses. With the right knowledge and guidance, consumers can navigate the complexities of the water pump market, ensuring that they invest in systems that serve both their needs and the environment. In this article, we will explore essential tips for choosing the best water pump for water, empowering you to make choices that benefit both your budget and the planet.

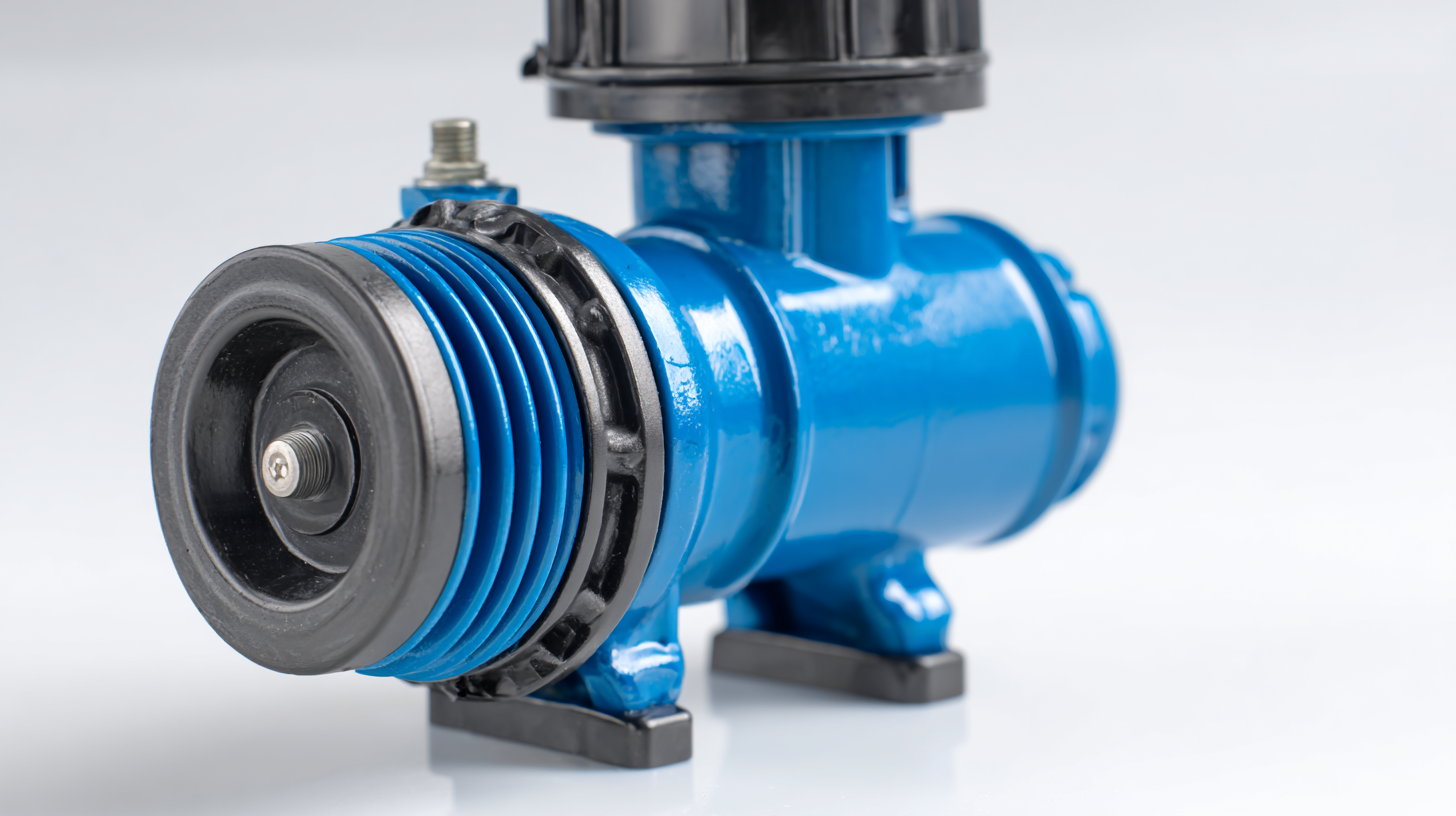

When selecting the right water pump, it’s crucial to understand the various types available and their efficiency levels. Centrifugal pumps are among the most common types and are known for their high efficiency, often achieving over 85% efficiency in properly designed systems. According to the U.S. Department of Energy, optimizing pump efficiency can result in energy savings of up to 50% in some cases, which is significant for both residential and commercial applications.

Submersible pumps, on the other hand, are designed for specific conditions, such as draining water from deep wells, and can have varied efficiency ratings based on their design and use case. Reports from the Hydraulic Institute indicate that improving the pump system can lead to an additional 20% energy savings beyond the pump's inherent efficiency. Understanding these differences is essential for making an informed decision, as the wrong choice can lead to increased operational costs and reduced water efficiency, impacting both the environment and your budget.

| Pump Type | Efficiency Level (%) | Best Use Case | Initial Cost ($) | Operating Cost (Annual) ($) |

|---|---|---|---|---|

| Centrifugal Pump | 70-85 | General Water Transfer | 500 | 150 |

| Submersible Pump | 80-90 | Deep Well Applications | 800 | 120 |

| Positive Displacement Pump | 85-95 | Viscous Fluids | 1000 | 200 |

| Jet Pump | 60-70 | Shallow Wells | 300 | 180 |

| Solar Water Pump | 75-85 | Remote Area Applications | 1200 | 0 (No fuel costs) |

When selecting a water pump, assessing your water needs is crucial for optimal performance and efficiency. According to the U.S. Department of Energy, irrigation is responsible for approximately 70% of freshwater withdrawals in agriculture, highlighting the significance of choosing the right pump to manage this resource efficiently. Understanding your specific water requirements—whether for residential use, agricultural irrigation, or industrial processes—will help you determine the flow rate and pressure needed, ultimately leading to more effective water usage and cost savings.

Moreover, industry reports suggest that selecting a pump with the appropriate capacity can reduce energy consumption by up to 30%. For instance, a study from the Water Research Foundation emphasizes the importance of sizing pumps correctly; an oversized pump not only wastes energy but may also lead to premature equipment failure and increased maintenance costs. By carefully analyzing your water consumption patterns and growth projections, you can make informed decisions and invest in pumps that not only meet your current needs but also adapt to future demands while maximizing efficiency and operational savings.

This chart illustrates the efficiency of various types of water pumps based on their flow rate and power consumption. The data showcases how choosing the right pump can lead to optimal water efficiency and cost savings.

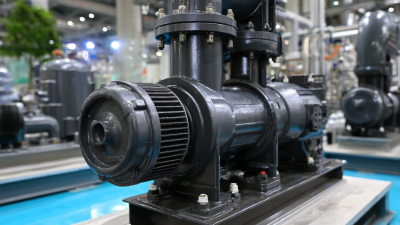

When selecting a water pump, evaluating the size and power is critical for maximizing cost savings and ensuring water efficiency. An undersized pump may struggle to meet demand, leading to increased runtime and higher energy bills. Conversely, an oversized pump can lead to short cycling, which not only wastes energy but also decreases the lifespan of the equipment. According to a report by the U.S. Department of Energy, pumps can account for nearly 20% of the total electricity consumption in industrial facilities. Therefore, a proper assessment of the pump's requirements based on your specific application is essential.

To determine the optimal pump size, one should consider the flow rate and head requirements. The Hydraulic Institute recommends conducting a thorough analysis of the system’s needs, including friction losses and required pressure at the discharge point. This will help in selecting a pump that operates efficiently within its best efficiency point (BEP). Using a pump that matches the operational parameters not only reduces energy consumption but also enhances performance reliability. A well-sized pump can lead to reductions in operational costs by as much as 30%, making it a vital aspect of any water management strategy.

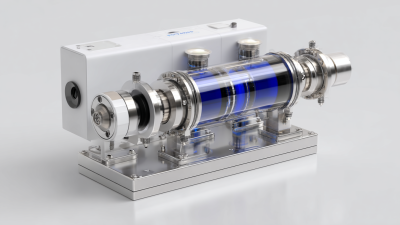

When selecting an energy-efficient water pump, it's crucial to understand the key features that enhance both water efficiency and cost savings. One of the most important factors is the pump's efficiency rating, often indicated by its Energy Efficiency Index (EEI). According to a 2022 report by the International Energy Agency, the proper selection of water pumps can cut energy consumption by up to 30%, resulting in significant savings over time.

Another essential feature to consider is the pump's adaptability to varying flow rates and pressure demands. Many modern pumps come equipped with variable frequency drives (VFDs) that adjust motor speed to match system requirements. This ensures that the pump operates at optimal efficiency, reducing energy waste. A tip for homeowners and businesses alike is to choose pumps with smart controls that monitor usage patterns, further enhancing operational efficiency.

Another essential feature to consider is the pump's adaptability to varying flow rates and pressure demands. Many modern pumps come equipped with variable frequency drives (VFDs) that adjust motor speed to match system requirements. This ensures that the pump operates at optimal efficiency, reducing energy waste. A tip for homeowners and businesses alike is to choose pumps with smart controls that monitor usage patterns, further enhancing operational efficiency.

Lastly, pay attention to the material and construction of the pump. High-quality materials not only improve durability but also contribute to energy savings by minimizing friction losses. The U.S. Department of Energy highlights that pumps constructed with corrosion-resistant materials can sustain higher efficiency levels over time. Investing in a quality pump can lead to reduced maintenance costs and extended service life, making it a smart choice for both environmental sustainability and budget management.

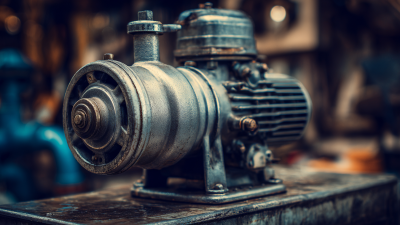

When selecting a water pump, understanding its maintenance is crucial for enhancing longevity and performance. Regular inspections are essential; check for leaks, wear, and noise levels. Addressing these issues promptly can prevent costly breakdowns and extend the pump's lifespan. A well-maintained pump not only functions better but also conserves energy, further contributing to cost savings.

Another important maintenance tip is to clean the pump's strainer and impeller regularly. This prevents debris build-up that can hinder performance. Ensure that the pump's mechanical seals are in good condition to avoid water loss and inefficiencies. Additionally, don’t forget to service the motor; lubricating bearings and checking electrical components can prevent unexpected failures and enhance the overall efficiency of your system.

Further, consider the environment in which the pump operates. Shielding it from extreme weather conditions can protect its components and minimize wear and tear. By implementing these maintenance strategies, you can ensure optimal performance, maximize water efficiency, and achieve significant cost savings over time.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.