Selecting the appropriate water pump for water applications is critical for ensuring efficiency, reliability, and sustainability in both industrial and residential settings. According to a recent report by the International Pump Manufacturers Association, the global market for water pumps is expected to reach $600 billion by 2025, driven by the increasing demand for water infrastructure and irrigation systems. The right pump not only enhances operational efficiency but also contributes to significant cost savings over time.

Industry expert Dr. Emily Thornton, a leading authority in hydraulic engineering, states, "Choosing the right water pump for water applications is not just about capacity; it’s about matching technology with the specific needs of your system." Her insights highlight the complexity of the decision-making process, which involves understanding various pump types, performance metrics, and application suitability. By leveraging the correct information, users can navigate this intricate landscape to find the optimal solution for their unique water handling needs. Therefore, equipping oneself with essential knowledge is paramount for making informed choices in the selection of a water pump for water applications.

When selecting the right water pump for your specific applications, several key considerations come into play to ensure optimal performance and efficiency. Understanding your water requirements is paramount; factors such as flow rate and total dynamic head (TDH) need to be carefully assessed. This involves calculating the volume of water needed and the height to which it must be pumped, as these elements will determine the type and size of pump suitable for your needs.

Additionally, energy efficiency should not be overlooked, especially in light of the rapidly growing household water pump market, projected to reach $26.9 billion by 2032, reflecting a compound annual growth rate (CAGR) of 4.8% from a value of $18.58 billion in 2024. Choosing a pump that operates efficiently can lead to significant savings in electricity costs over time. Lastly, consider the durability and material of the pump, as these will affect the longevity and maintenance needs of your system, ensuring your investment is sound for years to come.

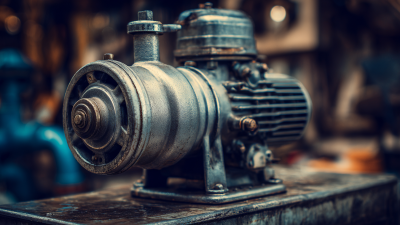

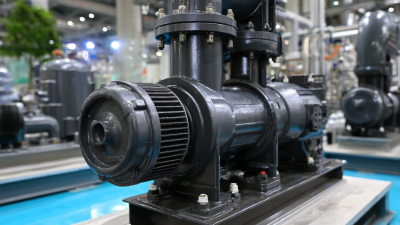

When selecting the right water pump, it's essential to understand the various types available and their specific applications. Centrifugal pumps, for example, are widely used for irrigation and water transfer due to their efficiency at moving large volumes of water. Their impeller design allows them to create a high flow rate, making them ideal for tasks requiring rapid circulation.

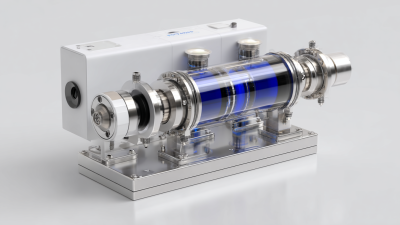

On the other hand, submersible pumps are designed to operate underwater, making them perfect for draining flooded basements or wells. These pumps are sealed to prevent water from entering the motor, ensuring durability in wet conditions. Additionally, positive displacement pumps can be advantageous for applications that require high pressure and low flow, such as chemical dosing or transferring viscous fluids. Understanding these distinctions will enable users to make informed decisions based on their specific water application needs.

When selecting a water pump for various applications, evaluating performance specifications is crucial for achieving optimal efficiency. Key specifications to consider include flow rate, head pressure, and power consumption. The flow rate indicates how much water the pump can move over a given period, which is essential for meeting the demands of your specific application. Conversely, head pressure measures the pump's ability to lift water vertically, which is vital for installations where water needs to be moved to higher elevations.

Another important aspect is the pump's efficiency rating. Look for models that offer high hydraulic efficiency to minimize energy consumption and operational costs. Additionally, understanding the pump's service factor can help in evaluating its longevity and reliability under varying operational demands. By carefully assessing these performance specifications, one can ensure that the chosen water pump operates efficiently while meeting the requirements of the application, ultimately leading to improved performance and cost savings over time.

When it comes to the longevity of water pumps, understanding the influencing factors is crucial. One key element is the operating environment. According to the Hydraulic Institute, environmental factors such as temperature, humidity, and the presence of corrosive substances can significantly impact pump lifespan. For instance, pumps used in aggressive chemical environments can deteriorate faster, with a reported reduction in lifespan by up to 50% if not correctly specified for such applications.

Another critical factor is maintenance. The American Society of Mechanical Engineers indicated that regular maintenance can extend the life of a water pump by as much as 60%. Simple tasks like checking seals, bearings, and impellers can prevent early failures. Additionally, using high-quality materials and components — as highlighted in a report by the European Pump Manufacturers Association — can also ensure that pumps withstand operational stresses over time, ultimately enhancing reliability and performance.

| Tip Number | Tip | Description | Influencing Factor | Impact on Longevity |

|---|---|---|---|---|

| 1 | Choose the Right Size | Select a pump that matches your specific water needs. | Flow Rate & Head Pressure | Improper sizing can lead to overheating and wear. |

| 2 | Consider the Pump Type | Different applications require different pump types (submersible, centrifugal, etc.). | Application Type | Using the wrong type can shorten the lifespan. |

| 3 | Evaluate Material Compatibility | Ensure that the pump materials are compatible with the fluids handled. | Corrosion Resistance | Corrosive fluids can cause significant damage. |

| 4 | Check for Energy Efficiency | Select pumps that reduce energy consumption. | Power Consumption | Efficient pumps often have longer operational life. |

| 5 | Regular Maintenance | Perform routine checks and maintenance to ensure efficiency. | Maintenance Schedule | Proper maintenance extends the pump's lifespan dramatically. |

When it comes to choosing the right water pump for various water applications, understanding the balance between cost and quality is crucial. Recent industry reports indicate that the global water pump market is projected to reach approximately $80.4 billion by 2027, growing at a CAGR of around 5.6%. This growth is driven by the increasing demand for efficient water management solutions across sectors such as agriculture, construction, and municipal water supply. Therefore, making an informed investment decision is essential to align with this market trend while ensuring that the selected pump meets specific operational requirements without inflating costs unnecessarily.

Cost considerations go beyond the initial purchase price of a water pump. Research suggests that operational costs, maintenance, and energy consumption make up a significant portion of the total cost of ownership over the pump's lifespan. A study shows that energy costs alone can account for up to 60% of these expenses, emphasizing the need for high-quality, energy-efficient pumps. By prioritizing quality, users can minimize long-term expenses while maximizing the efficiency and reliability of their water pumping systems. Ultimately, investing in quality water pumps can lead to substantial savings and improved operational outcomes in the long run.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.