Choosing water and pumps for various applications is crucial. The right selection can enhance efficiency and save costs. Your choices impact irrigation, industrial processes, and even household tasks.

In this guide, we will explore essential tips for selecting water and pumps. Finding the appropriate type involves understanding flow rates, pressure requirements, and energy consumption. Consider your specific needs, and remember that not every solution fits all situations.

While the selection process may seem straightforward, nuances exist. Some factors could lead to inefficiencies. This guide helps you reflect on common mistakes as you navigate the complexities of water and pumps. Let's dive into the details to make better choices.

Choosing the right water pump requires understanding your specific needs. Different pumps serve various purposes. For instance, submersible pumps are ideal for deep wells. They work underwater, drawing up water efficiently.

Tip: Assess your source depth before selecting a pump. Know where your water is coming from. This will save you headaches later. Did you consider the flow rate? It's essential for ensuring you have enough water when needed.

Another important factor is the pump's material. Some materials resist corrosion better. This is critical in certain environments. Think about the long-term costs and potential repairs. A cheaper pump might seem appealing but could lead to increased maintenance.

Tip: Always check the warranty. A solid warranty indicates a manufacturer’s confidence in their product. Don't overlook usability, too. A complex installation can become a major pain. Simpler setups help you avoid frustration down the line.

Choosing the right water pump involves several critical factors. One of the most important aspects is sizing. An undersized pump can lead to inefficiencies. It may struggle to deliver adequate water flow. This can cause frustration and additional costs over time. An oversized pump can also be a problem. It often results in unnecessary energy consumption and wear.

Consider the specific requirements of your project. Evaluate the total dynamic head, which includes the height the water needs to rise and any friction losses in pipes. These details matter. Calculate the flow rate needed for your application. This will help pinpoint the right size. Sometimes, people overlook the system’s operating conditions. Different temperatures and fluid types can impact performance.

It’s important to reflect on your long-term needs. Will your water consumption change? This can affect your choice. Avoid rushing the selection process just for expediency. Understand your requirements thoroughly. Mistakes here can lead to bigger issues later. Balance efficiency and performance in your decision. A thoughtful approach can save time and costs in the end.

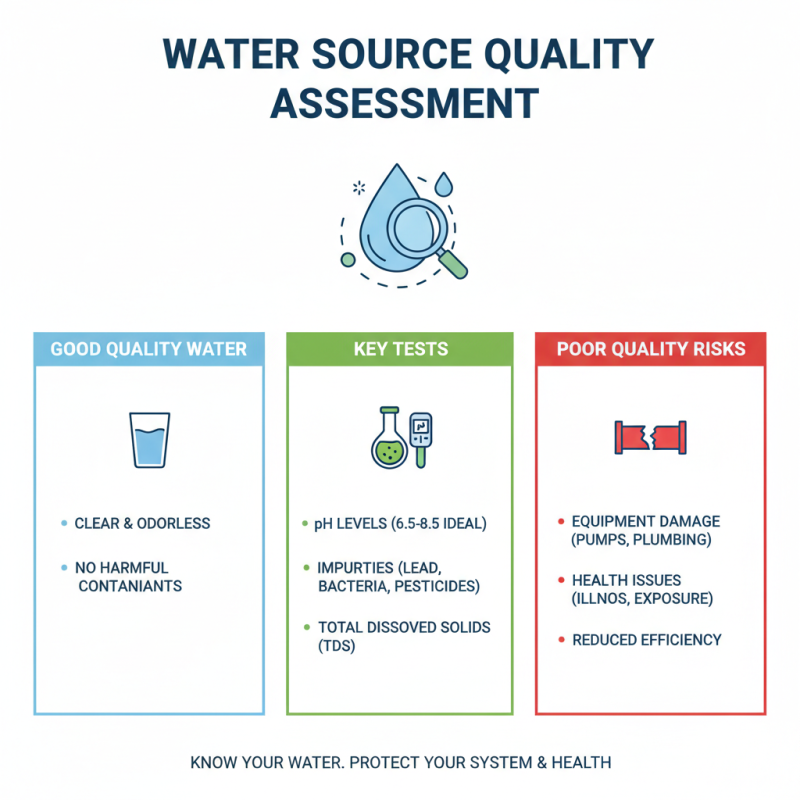

When assessing your water source, focus on its quality. Good quality water is clear and odorless. It should not contain harmful contaminants. Testing for pH levels and impurities can reveal a lot. Poor water quality can damage pumps and plumbing systems. It's vital to know what you're working with.

Understanding the local water source is equally important. Is it from a well or municipal supply? Each source has its own challenges. Wells may face issues like bacteria or mineral buildup. Municipal supplies can fluctuate in quality. You'll need to adapt your system accordingly. Observing changes in water clarity or taste can signal issues.

Don’t overlook maintenance. Even the best water can become problematic if neglect occurs. Regular checks can prevent unexpected breakdowns. Think about how often you test and inspect. Reflecting on past experiences can guide improvements. Choosing the right water source is not just about convenience; it’s about ensuring long-term performance.

When evaluating energy efficiency in pump selection, consider how energy costs impact overall operations. Pumps consume a lot of power. Choosing the right one can lead to significant savings. Look for pumps with high-efficiency ratings. They often have better performance and lower operational costs.

Selecting the right pump involves more than just specs. You need to assess the system’s actual needs. Oversized pumps waste energy; undersized ones put extra strain on the system. It's a balancing act. Testing different configurations can help find the sweet spot. Ensure the pump matches the specific requirements of your application.

One essential tip is to examine total lifecycle costs. Don't just consider the purchase price. Think about maintenance, energy, and repair costs over time. A cheaper pump may not always be the best choice. Evaluate how efficient it will be in real-world conditions. It’s important to reflect on past experiences and adjust your criteria accordingly.

Water pumps are essential for many systems, but maintenance is often overlooked. Regular checks can prevent costly repairs. Clean filters regularly to ensure efficiency. Clogged filters make pumps work harder and strain the system. This can lead to premature failure.

Lubrication is crucial for longevity. Use the right type of oil for your pump. Too much or too little can cause damage. Keep an eye on the seals. They can wear out, leading to leaks. Small leaks might seem insignificant but can cause big issues over time.

Ensure proper installation. Misalignment can lead to increased wear and tear. Hire a professional if needed. Routine inspections are necessary to catch small problems before they escalate. It's easy to overlook these details, but they can save both time and money in the long run. Regular maintenance creates a more efficient system. Consider developing a schedule to ensure nothing is neglected.

| Tip Number | Tip | Description | Frequency of Maintenance |

|---|---|---|---|

| 1 | Evaluate Water Quality | Test for pH, minerals, and contaminants to choose appropriate pump material. | Annually |

| 2 | Choose the Right Size | Select a pump that matches your water flow needs and system design. | Before Installation |

| 3 | Energy Efficiency | Opt for pumps with high energy ratings to save on energy costs. | Every 6 Months |

| 4 | Regular Inspections | Check for leaks, vibrations, or noise issues that indicate a problem. | Monthly |

| 5 | Install Filtration Systems | Protect pump and plumbing from debris and contaminants. | Before Pump Installation |

| 6 | Proper Ventilation | Ensure the pump is in a well-ventilated area to avoid overheating. | Ongoing |

| 7 | Use Appropriate Voltage | Select pumps that match your electrical system specifications. | Before Installation |

| 8 | Monitor Pump Performance | Keep track of discharge rate and efficiency over time. | Weekly |

| 9 | Schedule Professional Maintenance | Hire experts for annual or biannual check-ups and servicing. | Annually |

| 10 | Keep Documentation | Maintain records of inspections, maintenance, and repairs for future reference. | Ongoing |

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.