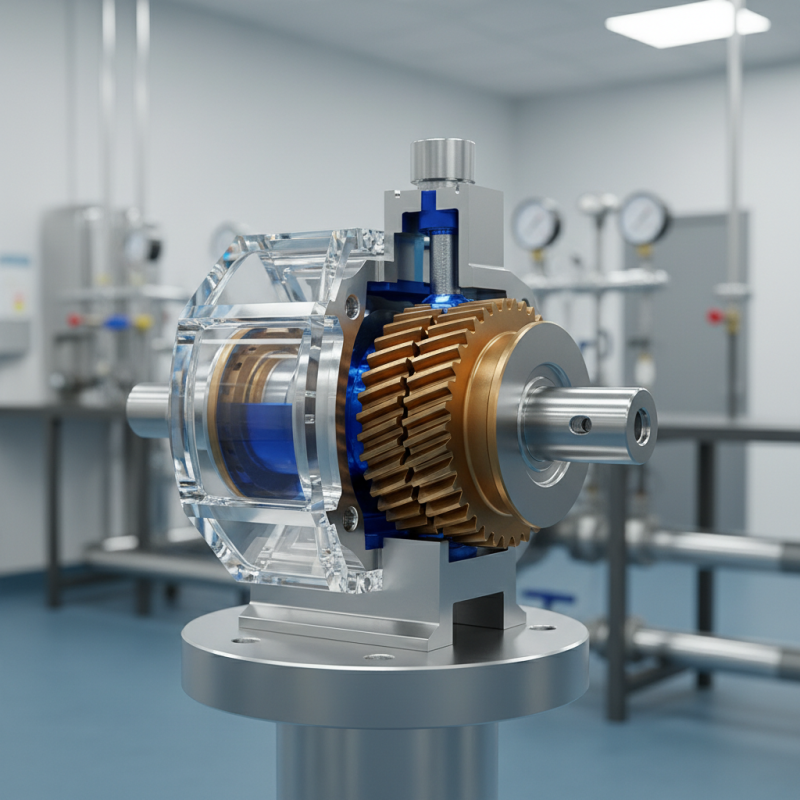

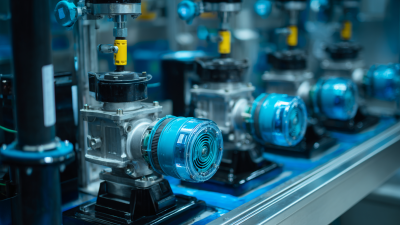

In the realm of fluid dynamics, gear pumps are vital components in numerous industries. As John Smith, a renowned expert in hydraulic systems, stated, "gear pumps are the engine behind many crucial operations." Their reliable performance contributes to effective machinery and ensures operational efficiency.

Gear pumps are essential for tasks requiring precise fluid transfer. They stand out for their durability and ability to handle high viscosities. These pumps can function in extreme conditions, maintaining performance even under pressure. However, not all applications benefit from gear pumps. Some scenarios may demand precision that gear pumps struggle to achieve.

The versatility of gear pumps is noteworthy. They excel in sectors such as automotive, construction, and manufacturing. Yet, a critical examination reveals limitations. Not every setup requires a gear pump. In some cases, alternatives can offer enhanced performance. Recognizing these nuances is crucial for selecting the right pump. This balance highlights both the strengths and weaknesses in the use of gear pumps.

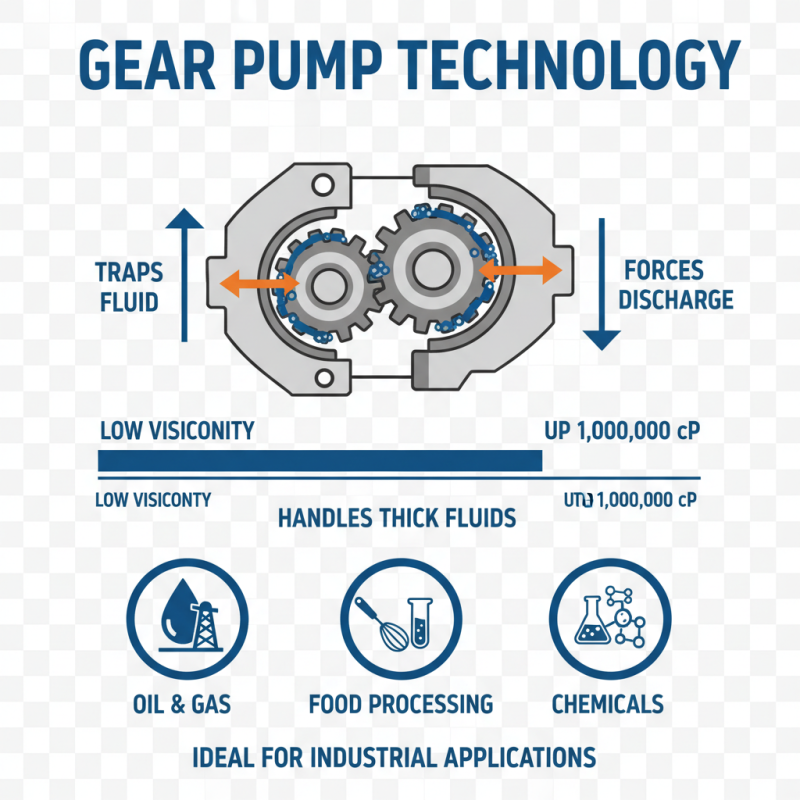

Gear pumps are essential in various industrial applications. They work by trapping fluid in the spaces between gear teeth and then forcing it through the discharge port. This process seems simple, yet it is effective in handling thick fluids. According to a recent industry report, gear pumps can efficiently transfer fluids with viscosities up to 1,000,000 centipoise. This makes them ideal for applications in oil, food processing, and chemical industries.

The functionality of gear pumps relies on their design. They typically have fewer moving parts, which results in lower maintenance needs. However, this does not mean they are without flaws. Some operators face challenges in ensuring a consistent flow rate and preventing leaks. Studies show that nearly 20% of gear pump failures stem from improper installation or maintenance. It's crucial to monitor wear and perform regular checks to uphold efficiency.

Despite their benefits, gear pumps do face limitations. They are not suited for handling solids or abrasive materials, which can damage the gears. Users must evaluate the fluid characteristics thoroughly before application. Overall, gear pumps offer distinct advantages, but understanding their operational limits is vital for optimal performance.

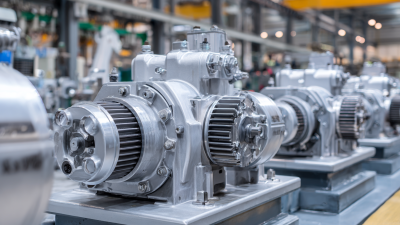

Gear pumps offer significant advantages across multiple industries. Their ability to provide a consistent flow makes them ideal for hydraulic systems. These pumps excel in situations that demand reliability and precision. The simplicity of their design allows for seamless operation in various settings. Industries such as automotive, manufacturing, and oil and gas heavily rely on gear pumps.

One of the key benefits is their efficiency in handling viscous fluids. They can manage thick liquids like oils, making them a preferred choice in lubrication systems. Their performance in high-pressure environments is commendable. However, these pumps can be sensitive to contamination. Regular maintenance is critical to avoid potential breakdowns. Additionally, not all gear pumps perform equally in every scenario. It requires careful consideration for optimal application.

Gear pumps play a crucial role in various industrial settings. They are known for their efficiency in transferring fluids. Their primary applications span across industries like oil and gas, food processing, and pharmaceuticals. According to a recent market report, the global gear pump market is expected to reach over $3 billion by 2025, reflecting a growing demand.

In the oil and gas sector, gear pumps handle viscous fluids effectively. They are often used to transfer crude oil, which can be challenging due to its thick consistency. Similarly, in food processing, gear pumps ensure precise flow rates during production. They help avoid contamination, as their design minimizes gaps where fluid can accumulate.

Tip: Always consider the viscosity of your fluid before selecting a pump. Understanding the fluid's characteristics can optimize performance. Additionally, regularly inspect your gear pump for wear. Neglecting maintenance can lead to inefficient operation.

In pharmaceuticals, gear pumps must meet strict hygiene standards. They reliably transfer ingredients without risking contamination. However, improper installation can lead to costly downtime. Reflect on your system’s design and ensure pumps are properly fitted and maintained.

Tip: Document all maintenance activities. This data can show trends and potential issues. It helps in proactive maintenance planning, ensuring reliability in critical applications.

| Benefit/Application | Description | Common Industries |

|---|---|---|

| High Efficiency | Gear pumps provide continuous, smooth flow with minimal pulsation. | Chemical, Food & Beverage |

| Self-Priming | Ability to draw fluid into the pump without needing external priming. | Water Treatment, Pharmaceutical |

| Durability | Designed for long-term operation with minimal maintenance. | Mining, Oil & Gas |

| Versatile Handling | Effectively handles various liquids, including viscous fluids. | Printing, Textile |

| Compact Design | Space-saving design suitable for limited installation areas. | Automotive, HVAC |

| Low Noise Levels | Operates quietly, making them suitable for sensitive environments. | Food Processing, Hospitals |

| Accurate Flow Rate | Provides precise flow control, essential for metering applications. | Pharmaceutical, Chemical |

| Cost-Effective | Offers a lower total cost of ownership due to durability and efficiency. | Manufacturing, Construction |

| Simplicity of Operation | Easy to use with minimal training required for operators. | Agriculture, Marine |

| Wide Range of Applications | Utilized in various sectors for transferring fluids in different conditions. | Energy, Construction, Water Treatment |

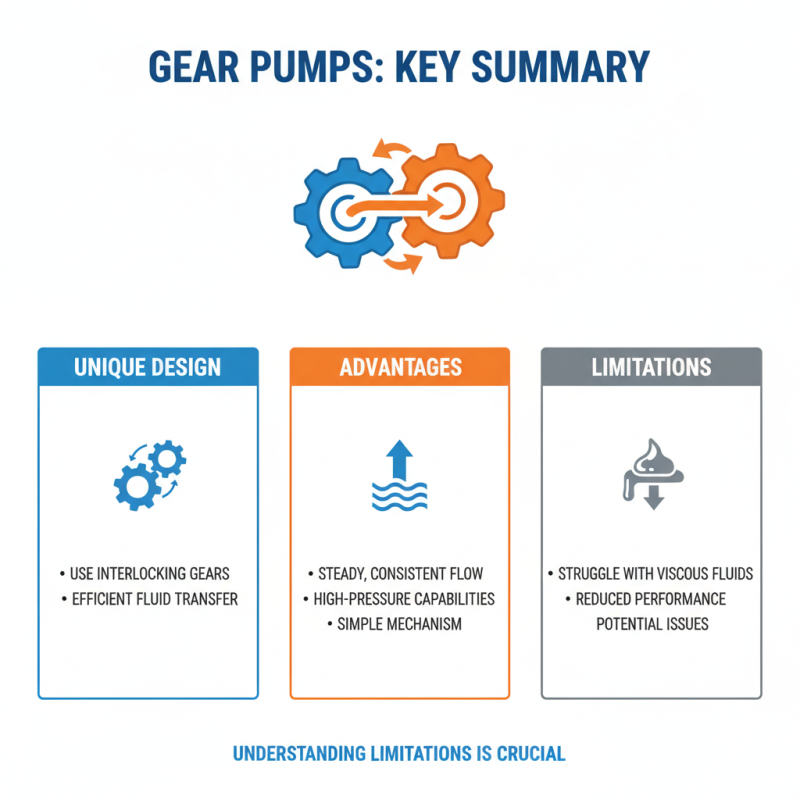

Gear pumps are unique in their design, which sets them apart from other pump types. They use gears to move fluids efficiently. This simple mechanism offers advantages like steady flow and high pressure. However, gear pumps can struggle with viscous materials. Their performance may drop, causing potential issues. Understanding these limitations is crucial for users.

In comparison, diaphragm pumps are notable for their ability to handle various fluids, including corrosive ones. They provide a pulsating flow, which might not be ideal for all applications. Centrifugal pumps offer a different approach, relying on rotational energy. While they excel in moving large volumes, they lack the consistent pressure of gear pumps. Each pump type has its strengths and weaknesses. Knowing these can guide proper selection for specific tasks.

Proper maintenance of gear pumps is crucial for optimized performance. Regular inspections help identify wear and tear. Check the seals and bearings often. They may need replacing over time. Dust and particles can accumulate, leading to inefficiency. Cleaning the pump regularly is essential. Use appropriate solvents for safe cleaning.

Lubrication plays a significant role in pump life. Always use recommended lubricants. Over-lubrication can be just as harmful as under-lubrication. Monitor the oil levels closely. If the pump operates in extreme temperatures, adjustments might be necessary. Don’t overlook the impact of temperature on pump materials.

Additionally, consider the operating environment. High humidity or corrosive atmospheres can affect performance. Avoiding abrupt starts and stops can also extend the unit’s lifespan. Reflect on any unusual noises during operation; they could indicate issues. Address these concerns promptly to prevent larger problems down the line.

This bar chart illustrates the top 10 benefits of gear pumps, showcasing their performance advantages and applications across various industries.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.