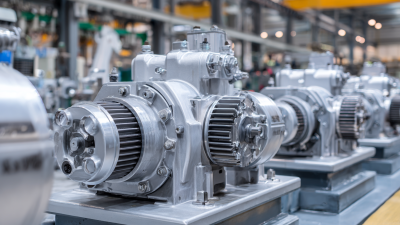

Choosing the right oil for gear is crucial for ensuring optimal performance and longevity of mechanical systems. According to a report by the National Lubricating Grease Institute, proper lubrication can reduce friction and wear by up to 60%, significantly prolonging equipment life. The viscosity, additives, and overall formulation of the oil for gear play vital roles in maintaining efficiency under various operating conditions. Additionally, the American Society of Mechanical Engineers highlights that using the appropriate lubricant can lead to energy savings of approximately 3-5%, thereby enhancing operational cost-effectiveness. As industries evolve and tasks become more demanding, understanding the intricacies of gear oil selection is imperative for engineers and maintenance professionals alike, making it an essential consideration in machinery design and upkeep.

When selecting the best oil for gear applications, understanding the distinction between synthetic and mineral oils is essential for enhancing performance and longevity. Synthetic oils are engineered for superior performance under extreme conditions, often providing better lubrication, thermal stability, and oxidation resistance compared to their mineral counterparts. This makes them a preferred choice for high-performance machinery and demanding environments.

When selecting the best oil for gear applications, understanding the distinction between synthetic and mineral oils is essential for enhancing performance and longevity. Synthetic oils are engineered for superior performance under extreme conditions, often providing better lubrication, thermal stability, and oxidation resistance compared to their mineral counterparts. This makes them a preferred choice for high-performance machinery and demanding environments.

Tips: When considering gear oil, assess the operating conditions of your equipment. If running at high temperatures or under heavy loads, synthetic oils may offer the reliability required. Additionally, check compatibility with your gear materials, as modern synthetic oils are designed to work well with various seal materials.

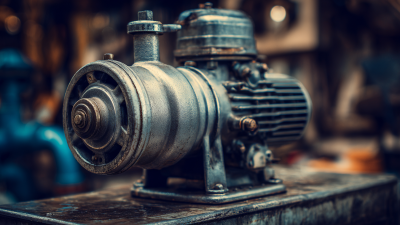

On the other hand, mineral oils, derived from refining crude oil, can be more cost-effective for standard applications. They deliver satisfactory performance for many conventional machinery setups. However, regular maintenance and oil changes should be emphasized, as they may not withstand harsh conditions as effectively as synthetic oils.

Tips: If your machinery operates under normal loads and temperatures, mineral oils may suffice. Always follow manufacturer recommendations for oil types to ensure optimal performance and longevity of your equipment.

When selecting the best oil for gear applications, understanding key properties such as viscosity, additives, and stability is crucial. Viscosity, or the thickness of the oil, directly impacts how well it can lubricate the moving parts within the gear system. A lower viscosity oil provides easier flow, ideal for cold conditions or high-speed operations, while higher viscosity oils are better suited for high-temperature environments where thicker lubrication is necessary to prevent wear and tear.

Additives are another essential component that enhances gear oil performance. These additives can improve oxidation stability, reduce foaming, and provide anti-wear properties. When choosing gear oil, look for formulations that contain EP (Extreme Pressure) additives, which ensure optimal protection under heavy loads and prevent metal-to-metal contact. Additionally, stability is important for maintaining the oil’s effectiveness over time. A stable gear oil will resist breakdown and maintain its properties even under extreme conditions, thus extending the lifespan of both the oil and the equipment it lubricates.

The quality of gear oil plays a crucial role in the overall performance and longevity of mechanical systems. High-quality gear oils reduce friction and wear, which can lead to better efficiency and a prolonged lifespan for your equipment. According to a report by the American Society of Mechanical Engineers (ASME), using synthetic gear oils can increase operational hours by up to 50% compared to conventional oils. This is particularly vital in high-load scenarios where the demand on gear systems can be significantly higher.

Tips: When selecting gear oil, always look for specifications that meet or exceed your equipment's requirements. Check for certifications such as API or ISO, as these can indicate a higher level of oil performance and protection.

Furthermore, contaminated or degraded gear oil can negatively impact performance, leading to premature failure. A study by the Society of Tribologists and Lubrication Engineers (STLE) indicates that regularly changing gear oil can reduce repair costs by up to 30%. Implementing routine maintenance and using high-quality oils can prevent minor issues from escalating, ensuring your machinery operates optimally.

Tips: Consider implementing a schedule for regular oil analysis to monitor the condition of your gear oil. This proactive approach allows for early detection of contaminants and ensures that you're always using the right oil for your needs.

When it comes to selecting the appropriate oil for your gear system, understanding API (American Petroleum Institute) and GL (Gear Lubricant) ratings is crucial for maximizing performance and longevity. The API performance classification indicates the quality and suitability of the oil for specific applications, while GL ratings specifically assess the oil's ability to protect gears under various load conditions. According to the American Gear Manufacturers Association, using the correct oil can reduce wear by up to 50% and extend the lifespan of transmission components considerably.

For instance, GL-4 oils offer adequate protection for gears operating under moderate loads and speeds, but for high-performance applications, GL-5 ratings are recommended due to their enhanced protection against extreme pressure and shock loads. A report from the Society of Tribologists and Lubrication Engineers highlights that using oil with the correct GL rating can lead to an increase in gear efficiency by 10-15%. Therefore, knowing the unique specifications of your gear system, along with API and GL ratings, will ensure optimal functionality and durability of your gears.

| Oil Type | API Rating | GL Rating | Viscosity | Temperature Range (°F) | Recommended Use |

|---|---|---|---|---|---|

| Synthetic Gear Oil | API GL-5 | GL-5 | 75W-90 | -40 to 140 | Heavy-duty applications |

| Conventional Gear Oil | API GL-4 | GL-4 | 80W-90 | -10 to 120 | Light-duty applications |

| High-Performance Gear Oil | API GL-5 | GL-5 | 75W-140 | -40 to 150 | Racing and heavy loads |

| Multi-Purpose Gear Oil | API GL-4 | GL-4 | 75W-85 | -30 to 130 | General use in various vehicles |

Changing your gear oil at the right intervals is crucial for maximizing the performance and lifespan of your machinery. Regular maintenance ensures that the gears are well-lubricated, reducing friction and wear. Typically, it's advisable to check your gear oil every 1,000 to 3,000 miles, though specific recommendations may vary based on the manufacturer's guidelines and the type of gear system in use. Factors such as operating conditions, load, and the type of oil used can also influence the optimal change schedule.

To determine when to change your gear oil, keep an eye out for any signs of degradation. If you notice a burnt smell, discoloration, or the presence of metal shavings in the oil, it’s time for a change. Additionally, consider documenting your oil changes to track performance trends over time. Regularly monitoring the condition of your gear oil not only enhances efficiency but also prevents potential mechanical failures, ensuring that your equipment operates smoothly for years to come.

This chart illustrates the performance scores of different types of gear oils: Synthetic Oil, Conventional Oil, and High Mileage Oil. Synthetic oil offers the best performance, making it ideal for high-demand applications.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.