In the realm of fluid transfer systems, maximizing the efficiency of gear pumps is critical for operational success, particularly in industries such as oil and gas, chemical manufacturing, and food processing. According to a report by the Hydraulic Institute, up to 30% of pump efficiency loss can be attributed to inadequate maintenance and the absence of vital gear pump spare parts. This underscores the necessity for operators to not only understand the functionality of their gear pumps but also to be equipped with the essential spare parts that ensure optimal performance. Proper selection and timely replacement of components, such as gears, seals, and bearings, can significantly reduce downtime and enhance productivity. By focusing on these critical gear pump spare parts, operators can effectively safeguard their investment and maintain seamless operations in an increasingly competitive market.

To achieve optimal gear pump performance, it's essential to identify and maintain key spare parts that directly influence efficiency. According to a report by the Hydraulic Institute, up to 30% of gear pump failures are attributed to wear on critical components such as gears and bearings. Regularly replacing these parts can significantly enhance pump reliability and avoid costly downtimes. The right maintenance strategy should include a thorough inventory of these spare parts, ensuring they are readily available when needed.

Another vital aspect to consider is the quality of replacement parts. A study published in the Journal of Fluid Power Systems highlighted that using genuine or high-quality aftermarket components can improve overall pump performance by as much as 25%. Key spare parts like shaft seals, O-rings, and filters play a pivotal role in preventing leaks and contaminants from disrupting the hydraulic circuit. Additionally, monitoring and replacing these components as part of a proactive maintenance schedule can lead to longer service intervals and lower operational costs. By focusing on these essential spare parts, operators can maximize gear pump efficiency and ensure sustained performance.

This bar chart illustrates the impact of essential spare parts on gear pump efficiency. Each component plays a crucial role in maintaining optimal performance and reducing downtime.

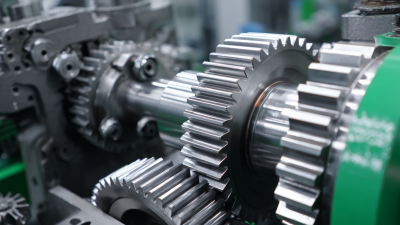

Seals and gaskets play a crucial role in maximizing the efficiency of gear pumps. These components are vital for preventing leaks, maintaining pressure, and ensuring optimal fluid transfer. A well-functioning seal not only protects against operational inefficiencies but also extends the lifespan of the pump by reducing wear and tear. Recent studies emphasize the importance of advanced sealing technology, which has shown promising results in enhancing energy performance and minimizing losses in high-speed pumps.

Furthermore, as the industry evolves, the demand for high-performance sealing solutions grows. Innovations in gasket design, such as those aimed at improving vacuum seal performance, are essential for meeting the rigorous demands of modern applications. By investing in quality seals and gaskets, operators can ensure their pumps function effectively, reduce maintenance costs, and increase overall system reliability. Ultimately, understanding the specific requirements of seals and gaskets can significantly enhance the performance of gear pumps, leading to greater operational efficiency.

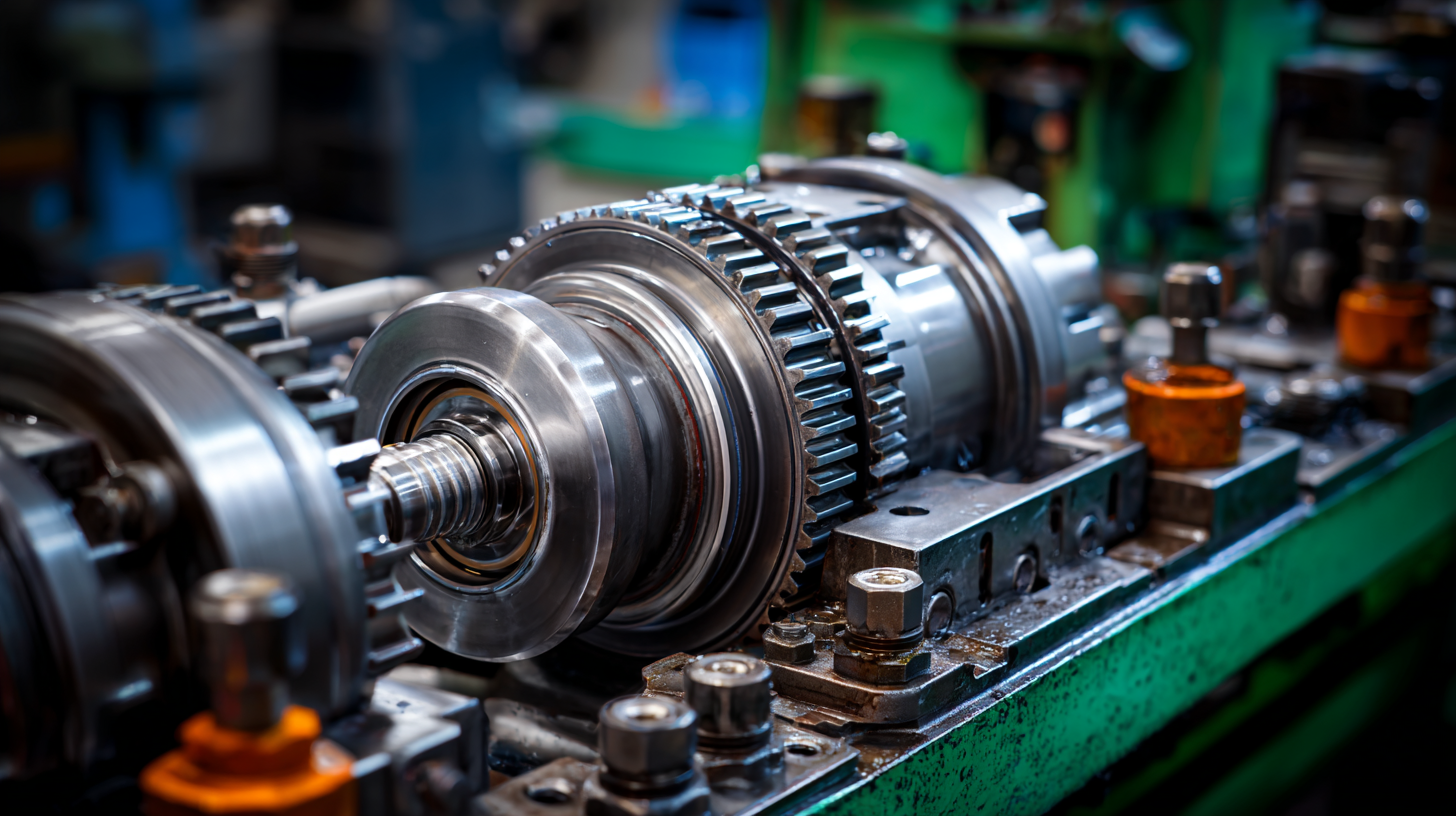

Bearings play a crucial role in the longevity and efficiency of gear pumps, serving as the backbone of rotating machinery. According to a report by the International Journal of Engineering Research and Applications, nearly 40% of pump failures can be traced back to bearings. This statistic underscores the importance of regular bearing inspection and replacement strategies to mitigate downtime and extend equipment life. Operators should prioritize high-quality bearings, as substandard components can lead to increased friction, heat generation, and ultimately, premature failure.

Moreover, the selection of the right type of bearing is essential to ensure optimal performance. Research from the Society of Tribologists and Lubrication Engineers indicates that the use of ceramic bearings can enhance durability and reduce maintenance frequency by up to 50% compared to traditional steel bearings. This improvement is particularly beneficial in applications facing extreme conditions, where wear and tear are accelerated. As operators aim to maximize gear pump efficiency, investing in quality bearings is a strategic necessity that contributes not only to longevity but also to overall operational effectiveness.

Filters play a crucial role in maximizing the efficiency of gear pumps, which are widely used in various industrial applications. According to a report by the Hydraulic Institute, up to 80% of pump failures can be attributed to contamination. The presence of particulates in the fluid can lead to increased wear on gear components, resulting in reduced performance and shorter lifespan. Implementing high-quality filters can significantly reduce the occurrence of these contaminants, thus enhancing the operational efficiency of gear pumps.

Effective filtration not only protects the pump but also optimizes its flow and pressure characteristics. A study published in the Journal of Fluid Mechanics reveals that a well-maintained filtration system can improve flow rates by as much as 15%. This is especially vital in demanding applications such as hydraulic systems, where maintaining optimal fluid cleanliness is essential for reliable operation. By routinely monitoring and replacing filters, operators can ensure that their gear pumps are running at peak efficiency, ultimately leading to reduced operational costs and improved machinery longevity.

| Spare Part | Description | Impact on Efficiency | Recommended Maintenance Frequency |

|---|---|---|---|

| Filters | Removes contaminants from the fluid | Prevents wear and tear, ensuring smooth operation | Every 3 months |

| Seals | Prevent leakage of fluid | Maintains pressure and efficiency in operation | Every 6 months |

| Gaskets | Ensure proper sealing between components | Reduces risk of contamination, enhancing performance | Annually |

| Pump Shaft | Connects the motor to the pump | Ensures consistent flow rate and power transfer | Every 2 years |

| Pressure Relief Valve | Prevents over-pressurization of the system | Protects equipment, enhancing longevity and performance | Every 6 months |

To ensure optimal performance and longevity of gear pumps, regular maintenance is imperative. A study by the American Society of Mechanical Engineers (ASME) indicates that improper maintenance is responsible for approximately 30% of all pump failures in industrial operations. By adhering to a structured maintenance schedule, operators can significantly increase the lifespan of their gear pumps and mitigate inefficient operation.

**Tip 1:** Regularly check and replace the lubrication oil in your gear pump. Contaminated oil can lead to excessive wear and premature failure, risking a potential repair cost increase of up to 50%, as highlighted in a report by Hydraulic Institute.

**Tip 2:** Conduct routine inspections for leaks and wear in seals and gaskets. A small leak can escalate into significant issues, potentially doubling energy consumption and cutting efficiency in half.

Incorporating these maintenance strategies not only extends the lifespan of gear pumps but also optimizes overall efficiency. Properly maintained equipment operates at peak performance, contributing to lower operational costs and minimized downtime, which is crucial in today's competitive market.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.