In the quest for enhanced operational efficiency and extended lifespan, optimizing water pump technology has emerged as a vital focal point within various industries. According to a report by the U.S. Department of Energy, inefficient pumping systems can account for up to 20% of a facility's total energy consumption, highlighting the critical need for improvement. The adoption of advanced water pump technology not only aids in reducing energy costs but also significantly lowers carbon emissions, aligning with global sustainability goals. Furthermore, the Hydraulic Institute emphasizes that implementing best practices in water pump maintenance and operation can increase longevity by up to 25%, ultimately leading to reduced downtime and repair expenses. This article explores effective strategies for optimizing water pump technology, ensuring that both efficiency and durability are achieved, thereby benefiting industrial operations and the environment alike.

When selecting the right water pump for your system needs, it is essential to consider various factors that directly impact efficiency and performance. First, assess the specific requirements of your application, including the desired flow rate and head pressure. Understanding these parameters allows you to choose a pump that matches your operational demands, ensuring optimal performance without unnecessary energy wastage.

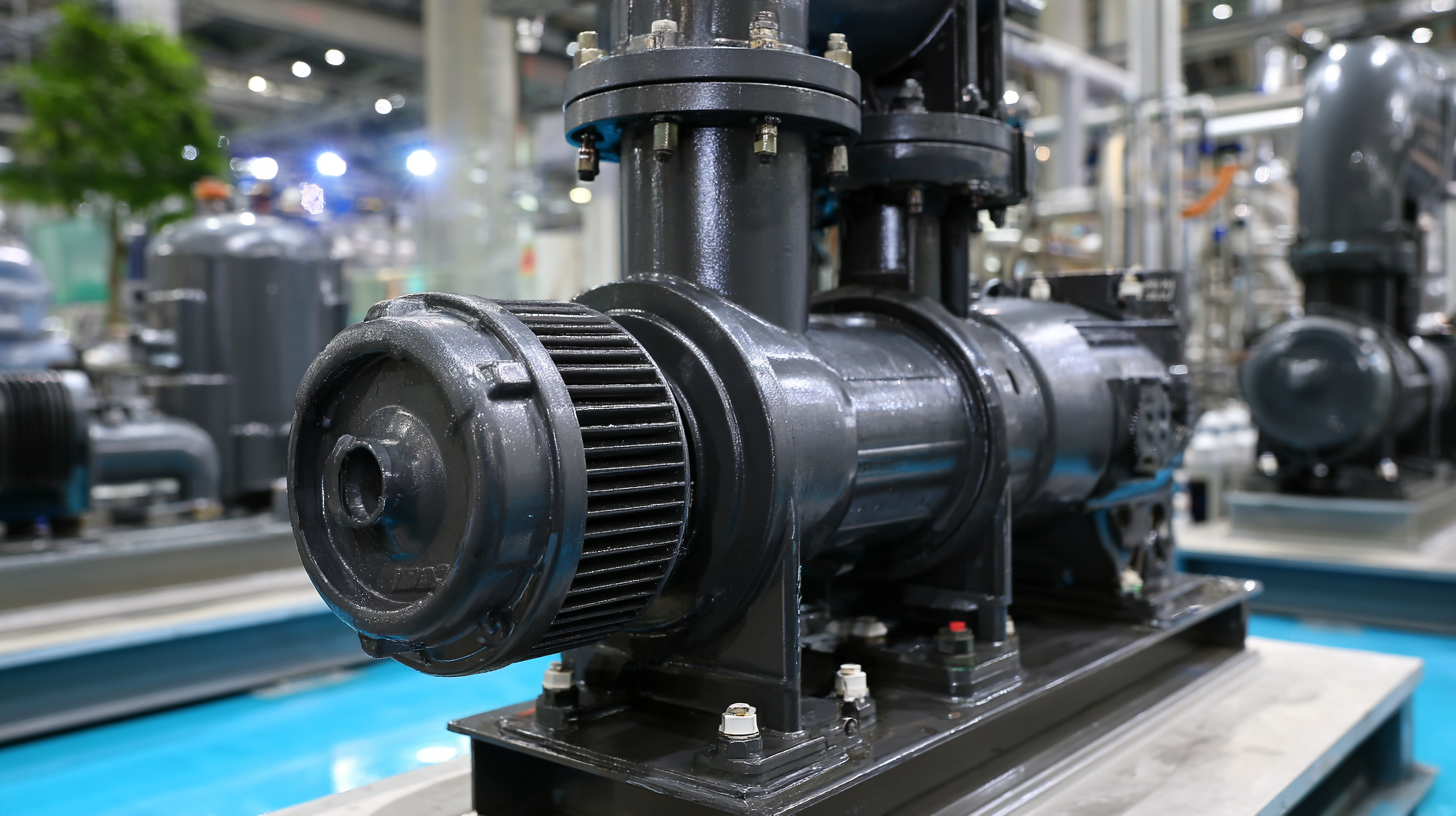

Additionally, consider the pump type best suited for your environment. Centrifugal pumps are ideal for high-flow, low-pressure applications, while positive displacement pumps excel in scenarios requiring precise flow control. Beyond the pump type, factor in the material construction based on the fluid being pumped, as well as the operating temperature and pressure. Compatibility with your system's infrastructure and maintenance requirements should also guide your selection, as these elements significantly affect the pump's longevity and reliability.

When evaluating the efficiency of water pumps, it's crucial to focus on key performance indicators (KPIs) that provide insight into their operational effectiveness. Some vital KPIs include flow rate, energy consumption, and pump head. The flow rate, measured in gallons per minute (GPM), indicates how much water is delivered over a period. Monitoring energy consumption helps in understanding the cost-effectiveness of the pump operation, while pump head signifies the energy available to overcome system resistance.

Tips for optimizing water pump technology include regularly monitoring these KPIs using digital gauges and flow meters. Implementing a routine maintenance schedule not only extends the lifespan of the pump but also ensures that the system operates at peak efficiency. Additionally, consider the use of variable frequency drives (VFDs) to adjust the pump speed according to the demand, which can significantly reduce energy consumption.

Investing in proper training for personnel handling water pump systems is another essential aspect. Knowledgeable staff can spot inefficiencies early, troubleshoot effectively, and make adjustments that maintain optimal performance. Combining these strategies will lead to improved pump longevity and operational efficiency.

Optimizing the pump system parameters is crucial for reducing energy consumption and enhancing the overall efficiency of water pump technology. By applying principles similar to those seen in the coal-fired power generation sector, where comprehensive design revisions lead to significant fuel consumption reductions, water pump systems can also achieve substantial energy savings. Analyzing existing designs to identify shortcomings will allow for fine-tuning of operational settings, such as flow rates and pressure levels, ensuring pumps operate at their optimal capacity.

Incorporating intelligent technologies and sensor systems can further elevate the efficiency of water pumps. As demonstrated in recent advancements in HVAC systems, smart technology enables real-time monitoring and adjustments, optimizing energy use without sacrificing comfort. This approach can be adapted to water pumping systems, allowing users to streamline operations and reduce wastage effectively. Ultimately, a system-wide perspective that transcends individual components is essential for achieving lasting improvements in efficiency and longevity of water pumps.

Regular maintenance is essential for extending the lifespan of water pumps, which are crucial for various applications in industries, agriculture, and households. One effective strategy is to establish a routine inspection schedule that includes checking the pump's components, such as seals, bearings, and impellers. Visual inspections can help identify any signs of wear or damage early, allowing for timely repairs and preventing larger, more costly failures down the line.

In addition to inspections, ensuring that the pump operates within its designed range is vital for longevity. Overloading a pump can lead to overheating and accelerated wear. Regularly monitoring performance metrics such as flow rates and pressure can help operators determine if the pump is functioning optimally. Furthermore, lubricant levels should be consistently checked and maintained to reduce friction and improve efficiency. Implementing these regular maintenance strategies not only enhances the water pump's efficiency but also significantly extends its operational life.

Innovations in water pump technology have significantly transformed the efficiency of hydraulic systems across various industries. Advanced materials, such as composite and corrosion-resistant alloys, are being utilized to enhance durability and reduce maintenance needs. Moreover, the integration of smart sensors allows for real-time monitoring of pump performance, enabling predictive maintenance that minimizes downtime and further optimizes operations.

Another key advancement is the development of variable frequency drives (VFDs), which facilitate precise control over pump speeds in response to fluctuating demands. This not only conserves energy but also extends the lifespan of the pump by reducing wear and tear caused by sudden changes in operational conditions. The implementation of energy-efficient designs and eco-friendly refrigerants are additional innovations that contribute to sustainable water pump systems, ensuring they meet contemporary environmental standards while delivering enhanced operational efficiency.

| Parameter | Value | Impact on Efficiency | Maintenance Frequency | Expected Lifespan |

|---|---|---|---|---|

| Pump Type | Centrifugal | High efficiency under specific flow rates | Monthly | 15 years |

| Pump Material | Stainless Steel | Corrosion resistance increases lifespan | Quarterly | 20 years |

| Motor Type | Variable Frequency Drive (VFD) | Improves adaptability and efficiency | Semi-Annual | 25 years |

| Seal Type | Mechanical Seal | Reduces leakage and wear | Annual | 10 years |

| Energy Source | Solar Power | Reduces operational costs significantly | Bi-Annual | 30 years |

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.