In the realm of hydraulic engineering, the efficiency and innovation of pump to pump water systems stand at the forefront of modern water management solutions. As global water demand continues to rise, driven by population growth and urbanization, the need for effective pumping systems has never been more critical. According to a report by the International Water Association (IWA), optimized pump systems can increase energy efficiency by up to 30%, significantly reducing operational costs and environmental impact.

Moreover, innovations such as variable speed drives and advanced control algorithms are transforming the landscape of water distribution, ensuring that these systems are not only efficient but also adaptable to fluctuating demands. This paper delves into the science behind pump to pump water systems, exploring efficiency metrics and the latest advancements in hydraulics that promise to enhance system performance and sustainability in the face of increasing global water challenges.

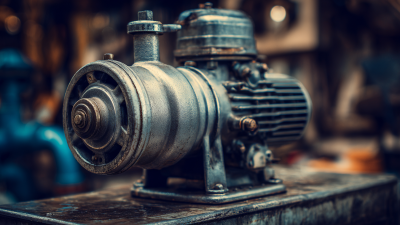

Pump to pump water systems play a crucial role in modern hydraulic applications, ensuring efficient water transfer across various sectors. These systems consist of interconnected pumps that work collaboratively to maintain the desired flow and pressure, optimizing performance. According to the Hydraulic Institute’s report, improving pump system efficiency can yield energy savings of up to 30%, highlighting the significance of understanding system basics such as pump sizing, selection, and layout.

When designing a pump to pump system, it’s essential to consider factors like flow rate and head that match the specific application requirements. Implementing variable frequency drives (VFDs) can enhance the system's adaptability, allowing pumps to adjust their speed based on demand and significantly reducing energy consumption.

**Tip 1:** Regular maintenance and monitoring can prevent system inefficiencies and prolong pump life.

**Tip 2:** Utilize advanced simulation tools during the design phase to predict system performance and identify potential issues before installation.

By grasping these foundational concepts, stakeholders can make informed decisions that lead to innovative solutions in hydraulic systems.

| Parameter | Value | Units |

|---|---|---|

| Flow Rate | 500 | L/min |

| Total Dynamic Head | 30 | m |

| Pump Efficiency | 85 | % |

| Power Consumption | 3.5 | kW |

| Water Temperature | 20 | °C |

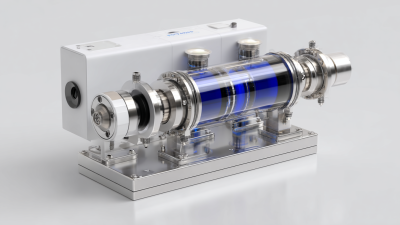

Key efficiency metrics are essential for evaluating the performance of pump to pump water systems. One crucial metric is the hydraulic efficiency, which measures the ratio of the useful work output by the pump to the energy input. This parameter helps assess how effectively a pump converts electrical energy into hydraulic energy, minimizing energy losses attributable to friction and turbulence in the system. A higher hydraulic efficiency indicates a more effective pump operation, leading to reduced operational costs and lower carbon footprints.

Another important metric is the overall system efficiency, which encompasses all components of the water delivery system, including pumps, pipes, and any auxiliary equipment. It provides a comprehensive picture of energy usage, helping engineers and operators identify opportunities for enhancements. Monitoring parameters such as flow rate, pressure, and power consumption allows for better analysis and optimization of system performance. Recent innovations in sensor technology and data analytics have further refined the ability to assess these metrics in real time, leading to smarter, more efficient water management solutions in hydraulic systems.

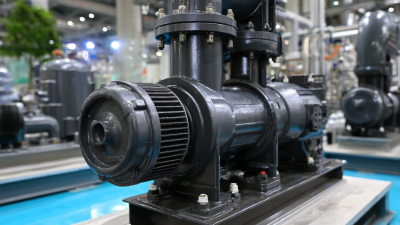

Innovative technologies in pump systems are steering a significant transformation in the hydraulics industry. According to a report by McKinsey, the global pump market is projected to grow to $73 billion by 2025, driven largely by advancements in smart technologies and digitalization. These innovations not only enhance operational efficiency but also reduce energy consumption and maintenance costs. For instance, the integration of IoT-enabled sensors allows for real-time monitoring and predictive maintenance, which can lead to a 20-30% decrease in downtime.

In addition, emerging technologies such as variable frequency drives (VFDs) are increasingly being adopted to optimize pump performance. A study by the American National Standards Institute (ANSI) indicates that implementing VFDs can improve energy efficiency by up to 50% in certain applications. Moreover, advanced materials and design methodologies are facilitating the development of lighter and more durable pumps, which further bolster performance while minimizing environmental impact. As these innovative solutions continue to reshape pump systems, the hydraulics sector is poised for a future marked by enhanced sustainability and efficiency.

In the realm of pump to pump water systems, optimizing integration is critical for enhancing efficiency and reducing operational costs. According to the Hydraulic Institute’s latest efficiency benchmark report, systems that adopt rigorous integration practices can achieve up to 25% energy savings compared to traditional setups. Key best practices include precise alignment of pumps to minimize hydraulic losses and incorporating variable frequency drives (VFDs) that allow for real-time adjustments based on demand. This adaptability not only ensures optimal performance but also contributes to a longer lifespan for the pump systems.

Moreover, recent advancements in control technologies have revolutionized pump integration. Utilizing smart sensors and IoT connectivity, operators can monitor performance metrics continuously, enabling predictive maintenance and reducing unexpected downtimes. A study by the American Society of Mechanical Engineers indicates that facilities leveraging these technologies have seen a 30% reduction in maintenance costs. Implementing such best practices not only fuels operational efficiency but also aligns with sustainability goals by minimizing energy consumption and reducing the carbon footprint of water management systems.

The future of pump system hydraulics is on the brink of significant transformation, driven by advancements in technology and increasing demand for efficient water management solutions. As the global market for intelligent and smart pumps is projected to reach $1.72 billion by 2025, with a compound annual growth rate (CAGR) of 7.5% until 2034, the focus on performance metrics and innovative designs is more critical than ever.

Tips: When considering upgrades to pump systems, it’s essential to analyze the energy consumption metrics of existing pumps. This can lead to substantial cost savings and enhance overall system efficiency.

Moreover, trends in the domestic booster pump market are also noteworthy, with forecasts indicating a substantial increase from $341.1 million in 2024 to $712.4 million by 2032, reflecting a CAGR of 9.64%. As innovations in hydraulics continue to evolve, the integration of renewable energy sources, such as solar-powered pumps, is also gaining traction, expected to grow from $15 million in 2022 to $42 million by 2030.

Tips: Investing in energy-efficient technologies can not only help in meeting regulatory standards but also position businesses favorably within a competitive marketplace.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.