A solution pump plays a vital role in various industries. Its main function is to move liquids efficiently. Understanding how this equipment works can greatly enhance productivity.

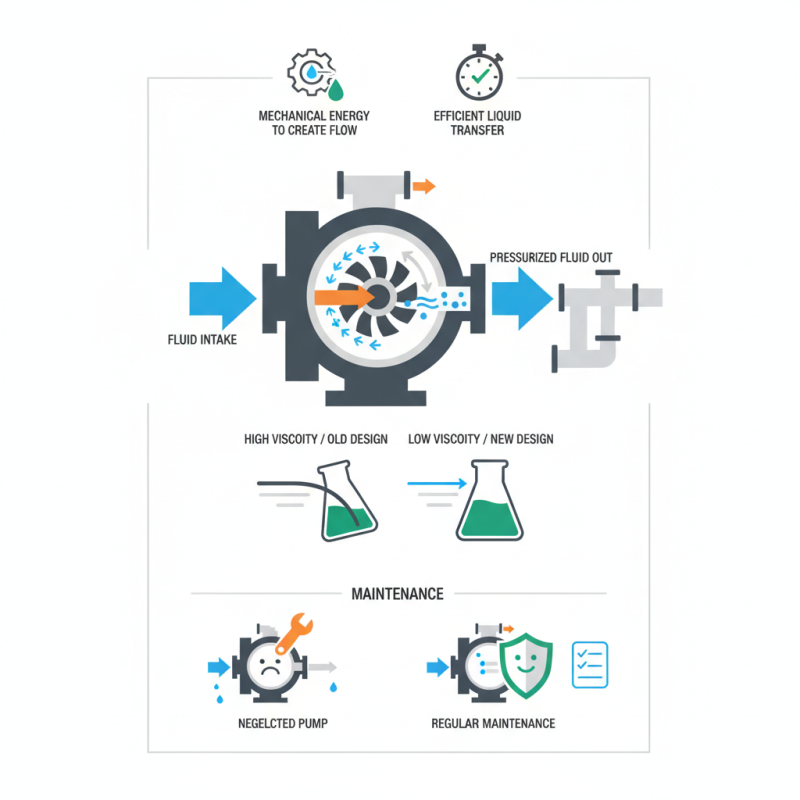

The solution pump operates by using mechanical energy to create flow. It draws in fluid and pushes it through pipes. This action streamlines the process, making it more effective than manual pumping. However, not all pumps perform equally. Factors such as fluid viscosity and pump design can impact efficiency.

In many cases, users may overlook maintenance. A neglected solution pump can lead to issues like reduced flow rates. Regular checks can prevent these problems. It's crucial to consider these details for optimal operation. Recognizing the importance of care and attention can make a significant difference in the performance of a solution pump.

A solution pump is a critical component in various industrial processes. It is designed to move liquids that contain dissolved solids or chemicals. Commonly used in fields like agriculture and chemical manufacturing, these pumps ensure efficient fluid transfer.

In the agricultural sector, solution pumps are essential for fertilizers and pesticides. According to a 2022 report by the Agricultural Engineering Society, approximately 70% of farmers utilize solution pumps to optimize their irrigation systems. This enhances crop yield and reduces water use, proving the pump's efficiency. However, improper maintenance can lead to clogs, seriously affecting performance.

The chemical industry also relies heavily on solution pumps for mixing and transporting chemicals. As noted in a recent market analysis by Chemical Processing Journal, demand for these pumps is projected to grow by 5% annually through 2028. Yet, the technology is not without flaws. Issues like corrosion and wear often arise, necessitating regular inspections to avoid costly downtimes. Understanding the challenges of solution pumps helps industries improve their operations and reduce risks.

| Parameter | Description |

|---|---|

| Type of Pump | Diaphragm Pump |

| Common Uses | Chemical processing, water treatment, agriculture |

| Flow Rate | Up to 200 GPM |

| Pressure Range | 10 to 100 PSI |

| Materials Used | Stainless steel, polypropylene, PTFE |

| Power Source | Electric motor or pneumatic actuator |

| Operation Method | Positive displacement |

| Maintenance Frequency | Every 6 months |

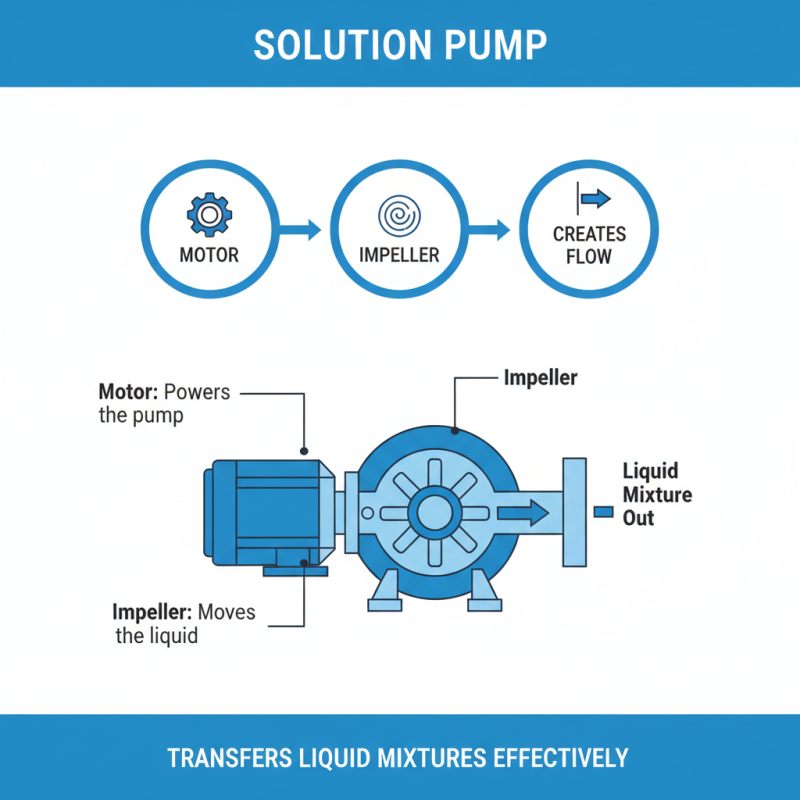

A solution pump is essential for transferring liquid mixtures effectively. Its main components work together to ensure smooth operation. At the core, you have the motor, which powers the pump. This motor drives the impeller. The impeller is crucial for creating flow by moving the liquid through the system.

Hoses and fittings connect the pump to the liquid source and discharge point. These components are designed to withstand pressure and prevent leaks. They must be durable to handle various substances. Filters often accompany solution pumps. They protect the pump from debris and clogs.

Commonly, the pump housing contains the internal parts. This sturdy casing keeps everything secure. Maintenance plays a significant role in the longevity of the solution pump. Regular checks can prevent breakdowns. The user must carefully monitor the performance. Over time, wear and tear can affect efficiency. Each component should be regularly assessed to ensure optimal function.

A solution pump is essential for various applications. Its operation relies on mechanical principles. Typically, it features a motor that drives a rotor. This rotor creates suction and pressure to move the solution. The design allows for efficient fluid transfer.

When considering installation, ensure the pump is properly aligned. Misalignment could lead to wear and tear. Proper maintenance is also critical. Regular checks can prevent unexpected failures. Even a small oversight can disrupt operations.

Tips: Keep an eye on the seals. They are vital for preventing leaks. Monitor the vibrations; unusual sounds can indicate problems. Always have a backup plan ready.

The mechanics of a solution pump may seem straightforward. However, it requires careful planning. Every component plays a role. Neglecting one could lead to inefficiencies. Investigate each part. Understand its function. This knowledge enhances overall performance.

Solution pumps play a vital role in many industries. They are used to transport various types of liquids, including chemicals and fertilizers. In agriculture, solution pumps help in irrigation systems. Farmers rely on these pumps to ensure that crops receive the right nutrients. The effectiveness of these pumps directly influences yield quality.

In the chemical industry, solution pumps handle corrosive substances. These pumps must be chosen carefully. Engineers need to consider factors such as pressure and viscosity. A poorly selected pump can lead to equipment failure. This affects production timelines and costs.

Water treatment facilities also depend on solution pumps. They are necessary for mixing different treatment chemicals. A consistent flow is crucial for maintaining water quality. However, maintenance of these pumps is sometimes overlooked. Neglected pumps can result in contamination. This highlights a need for regular checks and proactive management.

Solution pumps play a vital role in fluid management across various industries. They efficiently handle different types of fluids, making processes smoother and safer. According to a recent report, the global pump market is expected to reach $74 billion by 2026, driven mainly by the need for better fluid management solutions. Solution pumps can reduce downtime, but they require regular maintenance to function optimally.

One of the significant benefits of using solution pumps is their ability to manage viscous fluids. This feature is crucial in industries like chemical manufacturing, where fluid viscosity varies widely. A study revealed that companies using solution pumps report a 30% increase in efficiency. However, improper installation or lack of operator training can lead to failures or inefficiencies.

Furthermore, solution pumps contribute to sustainability efforts. By optimizing flow rates and minimizing leaks, they lead to reduced waste. The Environmental Protection Agency highlights that efficient fluid management is key to reducing operational costs. While solution pumps offer many advantages, it’s essential to remember that they are not a one-size-fits-all solution; careful consideration of the specific application is necessary.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.