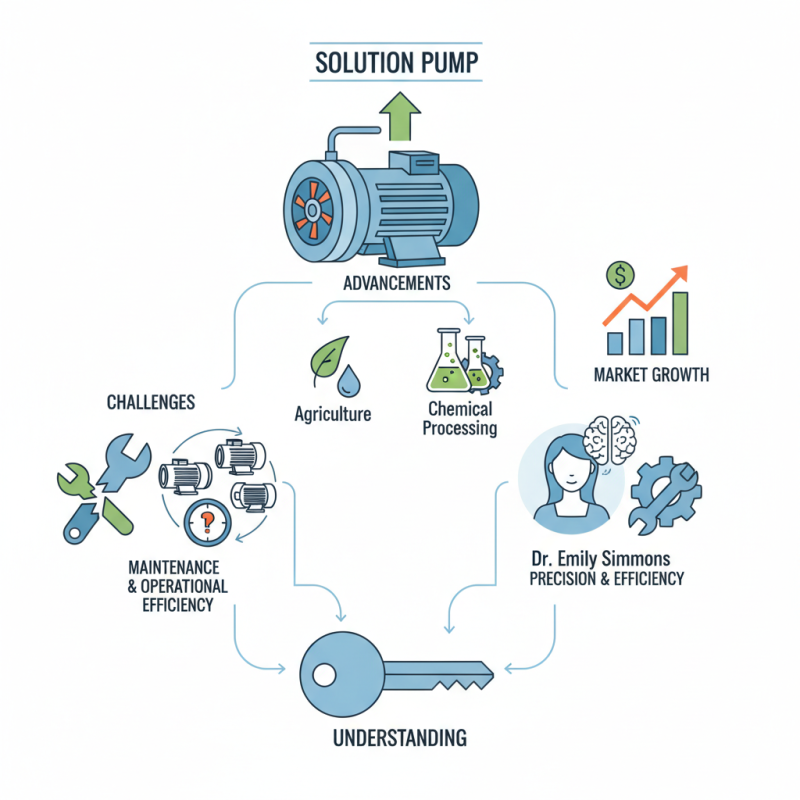

In recent years, the solution pump industry has seen significant advancements, driven by the growing demand for efficient fluid management. According to a report by MarketsandMarkets, the solution pump market is projected to reach $X billion by 2025, highlighting its increasing importance in various sectors. Engineers rely on these devices for precise fluid delivery in applications such as agriculture and chemical processing.

Dr. Emily Simmons, a renowned expert in fluid dynamics, states, "The solution pump is essential for achieving accuracy in fluid applications." Her work underscores the critical role that solution pumps play in ensuring efficiency and reliability in numerous industries. Despite their advancements, challenges remain. Many businesses still struggle with pump maintenance and operational efficiency. Addressing these issues is vital for future growth.

Moreover, the diversity of solution pump designs can complicate selection processes. Companies often face confusion when aligning specific pump types with their operational needs. Understanding the intricacies of solution pumps is key to overcoming these hurdles.

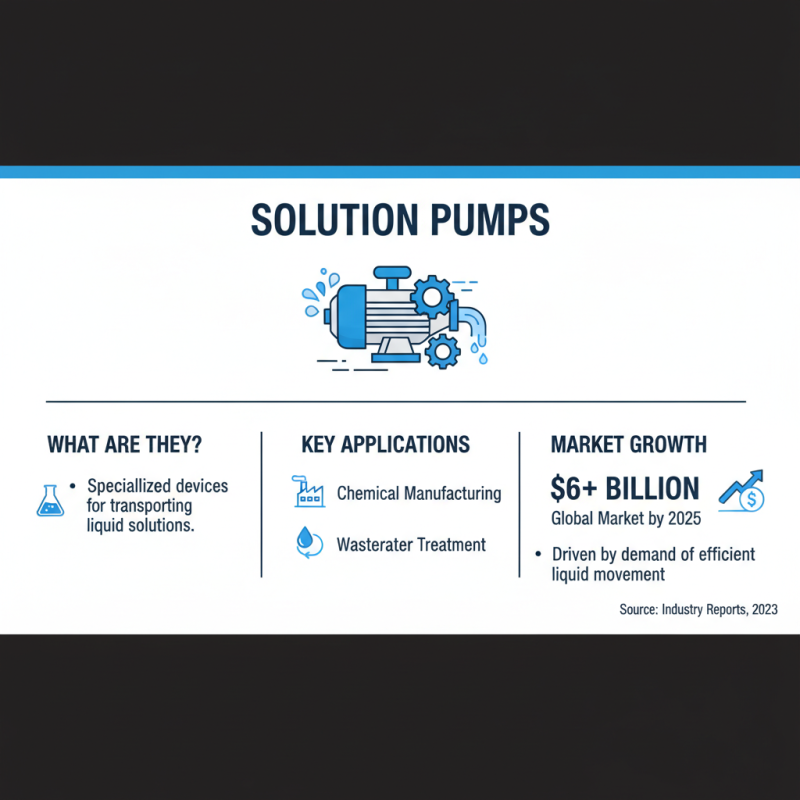

A solution pump is a specialized device designed to transport liquid solutions, particularly in industrial processes. These pumps play a crucial role in various applications, including chemical manufacturing and wastewater treatment. According to industry reports, the global market for solution pumps is expected to reach over $6 billion by 2025, driven by increasing demand for efficient liquid movement.

The operation of a solution pump involves several key components. It typically uses a motor to drive an impeller or diaphragm, creating a vacuum that draws fluid into the pump. This process can be highly efficient, but not without potential issues. For instance, cavitation can occur if the pump operates below its required flow rate. This can lead to decreased performance and equipment damage.

Maintenance is another important aspect of solution pump functionality. Regular checks can prevent breakdowns and enhance efficiency. However, many facilities struggle to implement effective maintenance schedules. This neglect can lead to costly repairs down the line. Reliable data indicates that companies often lose up to 20% of their operational efficiency due to poor equipment maintenance practices.

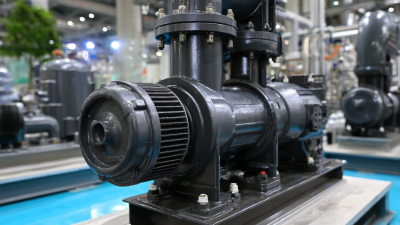

A solution pump is a crucial piece of equipment in various industrial applications. Understanding its components helps us appreciate its functionality. At its core, a solution pump comprises several key parts: the motor, impeller, and housing. Each component plays a role in moving liquid materials efficiently.

The motor powers the entire system. Its energy is transformed into mechanical motion. This motion drives the impeller, a fan-like structure that propels the liquid. As the impeller spins, it creates a vacuum that draws the solution in. The housing surrounds the impeller, directing the flow of liquid while maintaining pressure. This design is essential for effective operation.

However, not every solution pump is flawless. Wear and tear can affect performance. Issues may arise from improper installation or maintenance. It's important to regularly check seals and connections. Neglect can lead to leaks or reduced efficiency. Reflecting on these aspects can guide improvements in design and usage.

A solution pump plays a crucial role in various industrial applications. It's designed to transport fluids efficiently. Understanding how a solution pump operates helps businesses optimize performance.

The core operation involves a series of mechanisms that draw in the fluid. Once the fluid enters the pump, it is pressurized and directed through the outlet. According to industry reports, solution pumps can achieve flow rates ranging from a few gallons to several thousand gallons per minute. This versatility is essential for different operational needs.

Tips for maintaining a solution pump include regular inspections to catch wear and tear early. Monitor pressure levels closely. Sudden changes might signify issues needing immediate attention. Additionally, ensure the fluid’s viscosity matches the pump’s specifications. Operating outside these parameters can lead to inefficiencies and damage.

While solution pumps are efficient, they aren’t without challenges. Users often overlook the importance of cavitation, which can severely impact performance. If air gets trapped, it creates bubbles, reducing pumping capability. Regularly checking for potential cavitation problems is vital for sustained efficiency.

Solution pumps play a vital role in various industries. Their ability to handle viscous fluids makes them essential in chemical processing. According to a recent market report, the solution pump market is expected to grow at a compound annual growth rate (CAGR) of 4.2% from 2021 to 2026. This growth reflects increased demand for effective fluid management in industrial applications.

In the agricultural sector, solution pumps facilitate precise nutrient delivery. By ensuring accurate mixing of fertilizers and water, these pumps contribute to better crop yields. For example, in hydroponics, solution pumps maintain optimal nutrient levels, which directly impacts plant health. A study showed that proper nutrient management can increase productivity by up to 30%. However, selecting the right pump can be daunting due to varying specifications and requirements.

In water treatment facilities, solution pumps help manage chemical dosing. They ensure consistent and accurate addition of chemicals for disinfection processes. Miscalculations or pump failures can lead to unacceptable water quality. According to industry reports, nearly 20% of water treatment facilities report challenges with chemical injection. Addressing these issues is crucial for maintaining compliance and environmental standards.

This bar chart illustrates the common applications of solution pumps across various industries, showcasing the number of installations in each sector. Agriculture leads with the highest number of installations, followed by the chemical industry, highlighting the diverse use of solution pumps in different fields.

Solution pumps play a crucial role in various industrial applications. They are designed to move liquid solutions efficiently. However, their advantages and limitations can significantly impact their effectiveness.

One major advantage of solution pumps is their ability to handle thick, viscous fluids. This capability makes them ideal for industries like mining or chemical processing. They can also maintain a consistent flow rate, which is essential for precise operations. However, these pumps can be expensive to maintain. Their mechanical components may require frequent replacements, leading to increased operational costs.

Another limitation is their susceptibility to clogging. Particles in the solution can accumulate, causing blockages. This issue can halt production, resulting in costly downtime. Additionally, solution pumps may not perform well with varying pressures. Fluctuations can affect their efficiency and lead to inconsistent results. While solution pumps offer advantages, their drawbacks should not be underestimated. Frequent assessments and improvements are necessary to ensure optimal performance.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.