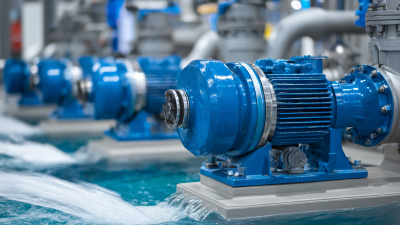

Choosing the right quality pumps is essential for various applications. Whether for industrial use or residential tasks, pumps play a critical role. However, not all pumps are created equal. The market is flooded with options, making it daunting to find the best choice.

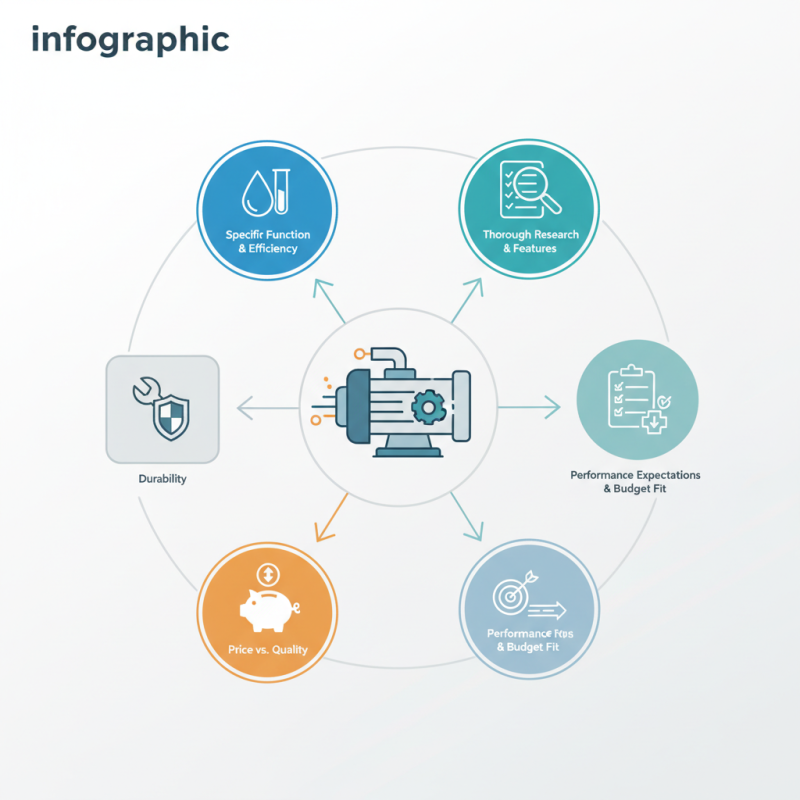

When selecting quality pumps, consider their specific function and efficiency. Are you using them for water transfer or chemical processing? The intended use greatly influences your decision. Durability is another key aspect; you want pumps that will last. Look for materials that withstand wear and tear.

Price can be misleading. A higher price does not always mean better quality. Perform thorough research to understand the features and specifications that suit your needs. Remember, a pump should not only fit your budget but also meet performance expectations. The goal is to find quality pumps that truly deliver for you.

When choosing a pump, understanding its type is crucial. There are several categories, each designed for specific applications. Centrifugal pumps are popular in water supply systems. They move fluid using a rotating impeller. This design helps achieve high flow rates. However, they may struggle with viscous fluids.

Positive displacement pumps operate differently. They trap fluid and force it through the discharge. These pumps are ideal for handling thick liquids, like slurries or oils. Keep in mind that they can create high pressure. This aspect needs careful consideration in your design.

Submersible pumps operate underwater. They prevent cavitation, making them efficient for draining and sewage applications. Despite their advantages, maintenance can be tricky. Ensure you have easy access for repairs. Selecting the right pump means assessing your specific needs. Each type has strengths and weaknesses that affect performance.

When choosing the right pump, understanding specifications is crucial. Flow rate indicates how much fluid can be moved in a specific time. Higher flow rates are necessary for larger applications, while smaller settings may require varied flow dynamics. It’s beneficial to assess your actual needs before making a decision. Ignoring this aspect can lead to inefficiencies and frustration.

Pressure is another key component. It defines the force at which the fluid is delivered. A pump with inadequate pressure may not meet the operational requirements. It’s important to analyze the system’s overall design and the purpose of the pump. Many overlook this, leading to unexpected downtime.

Efficiency plays a vital role in overall performance. An efficient pump saves energy and resources. Yet, efficiency ratings can sometimes be misleading. Always cross-check data and consider real-world applications. Inadequate information may result in choosing a pump that underperforms in critical situations. A careful evaluation is essential to avoid regrets later on.

When selecting pumps for corrosive or abrasive fluids, material choice is crucial. Different fluids react differently with various materials. Stainless steel, for example, is often resistant to corrosion, making it a common choice. However, it might not be the best for all applications. Some fluids can still cause damage over time. This aspect requires careful consideration.

Another tip is to think about compatibility. Rubber and certain plastics may offer excellent resistance to specific fluids. Yet, they might degrade unexpectedly. Testing the compatibility of materials before purchase is smart. Users often overlook this detail.

Don't forget about pump maintenance. Regular checks can reveal wear and tear. If you notice corrosion, that might signal a material mismatch. Addressing issues early is better than delayed reactions. Ignoring them can lead to costly downtime and repairs.

| Tip No. | Tip Description | Material Consideration | Best Applications |

|---|---|---|---|

| 1 | Evaluate the fluid characteristics. | Corrosive fluids may require stainless steel or specialized coatings. | Chemical processing, wastewater treatment. |

| 2 | Understand the viscosity of your fluids. | Heavy fluids may need positive displacement pumps. | Oil and gas, food processing. |

| 3 | Consider the pump's operating pressure. | Higher pressures require robust materials like duplex stainless steel. | Petrochemical, mining industries. |

| 4 | Assess the potential for abrasiveness. | Use hard alloy or ceramic materials for high-abrasion environments. | Mineral processing, dredging. |

| 5 | Check compatibility with existing systems. | Ensure materials are suitable for temperature and chemical exposure. | Manufacturing, HVAC systems. |

When assessing pump reliability, maintenance requirements are crucial. Regular checks prevent unexpected failures and extend the pump's lifespan. Inspect seals and bearings frequently. This helps identify wear before it leads to bigger issues. A proactive approach saves time and money in the long run.

Consider the materials used in the pump construction. Different environments may cause corrosion or abrasion. Choosing the right materials can minimize maintenance work. Avoiding costly repairs keeps operations smooth. Monitor the pump’s performance closely. Even minor changes can indicate potential problems. Address these early for optimal functionality.

A well-maintained pump can last years. Yet, not all pumps will perform equally over their lifetime. Some may require frequent servicing due to design flaws. Recognize the signs of declining performance, such as unusual noises or vibrations. Ignoring these can lead to system failure. Regular attention can help prevent such scenarios.

Choosing the right pump involves more than just cost. Many industries are facing budget constraints but cannot compromise on quality. According to a recent industry report, around 30% of operational costs stem from inefficient pump systems. Investing in quality pumps can significantly reduce maintenance expenses and downtime.

Balancing cost and performance is crucial in pump selection. A study found that quality pumps can enhance efficiency by up to 25%. This is vital for processes that depend on precise flow rates. However, cheaper options may lure buyers with attractive price tags, leading to higher long-term expenses. It’s essential to evaluate the total cost of ownership, including installation, maintenance, and energy expenses.

Quality pumps should also meet specific performance standards. Data indicates that over 40% of pump failures are due to improper selection. Assessing the application requirements and environmental conditions is key. Understand your operational needs clearly. This awareness helps avoid choices that might save money upfront but lead to complications.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.