Understanding pump spare parts is essential for effective maintenance and operation. Pumps play a crucial role in various industries. When they fail, the right spare parts can make a significant difference.

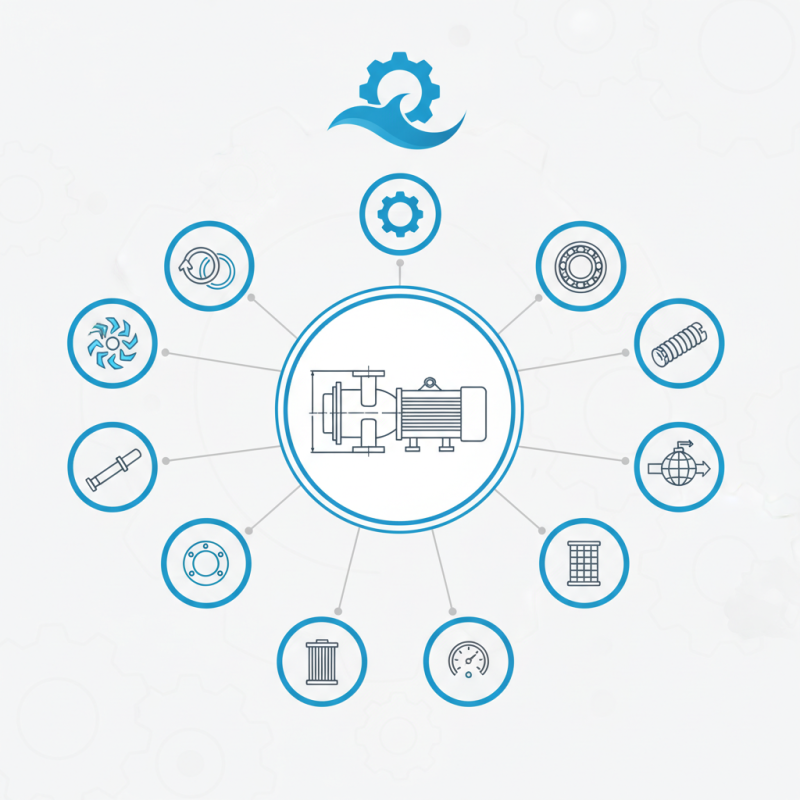

In this guide, we'll explore the top ten pump spare parts every operator should know. Familiarity with these components can help reduce downtime. Choosing the correct spare parts often feels overwhelming. Each component has a specific role in ensuring optimal pump performance.

We’ll dig into items like impellers, seals, and bearings. Each part is vital yet can easily be overlooked. Knowing their functions can prevent costly repairs. Neglecting to consider the right spare parts may lead to inefficiencies. Ultimately, understanding these essentials can enhance reliability and longevity in pump operations.

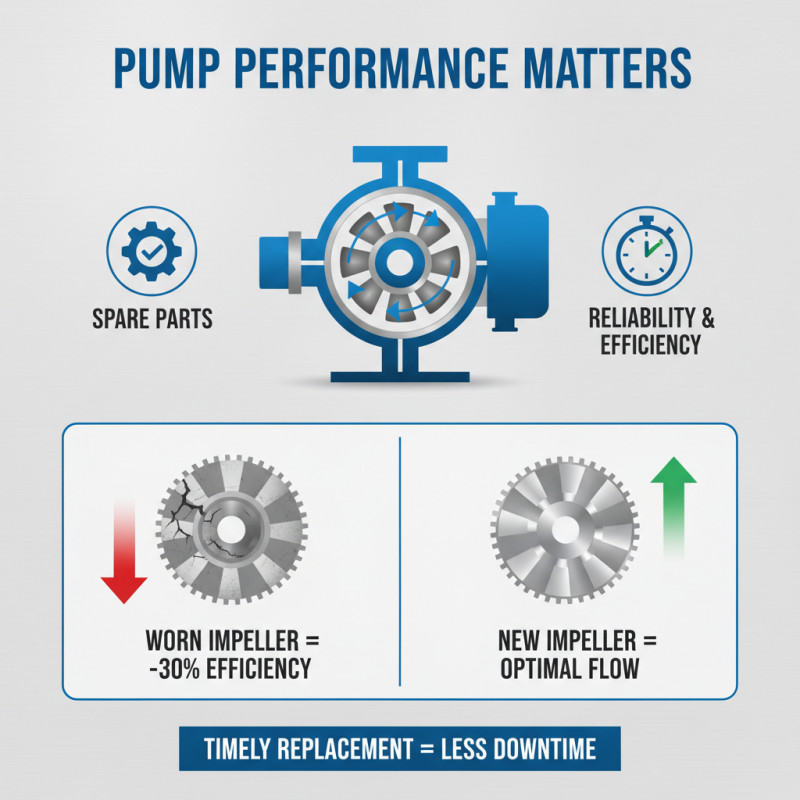

When it comes to pump performance, spare parts play a critical role in ensuring efficiency and reliability. One essential component is the impeller. It directly influences fluid movement and affects pump efficiency. Industry reports show that a worn-out impeller can decrease performance by as much as 30%. Regular monitoring and timely replacement can prevent unnecessary downtime.

Another vital part is the mechanical seal. It prevents leakage and protects internal components. A faulty seal can lead to significant fluid loss and increased energy costs. According to market analysis, over 40% of pump failures are linked to seal issues. Maintaining this small yet crucial component is key to operational success.

An often-overlooked item is the bearing. It supports rotating shafts and reduces friction. Bearings can fail unexpectedly, leading to catastrophic results. They require routine checks for wear and tear. Research indicates that proper lubrication can extend bearing life by up to 50%. Ensuring these parts are in top condition can make a significant difference in pump performance.

Understanding pump spare parts is essential for maintaining operational efficiency. Each component plays a specific role. For instance, an impeller converts rotational energy into kinetic energy. A study shows that over 54% of pump failures are linked to impeller wear. Regular monitoring can prevent significant downtime.

Seals are another vital component. They prevent leaks and ensure fluid containment. According to a recent reliability report, proper sealing can enhance pump life by up to 40%. However, seals can wear out quickly due to thermal stress and pressure changes. Neglecting their condition can lead to operational inefficiencies.

Bearings support the rotor and reduce friction. If bearings fail, it can lead to catastrophic failure. Data indicates that more than 30% of maintenance costs come from bearing replacements. Regular inspections and grease application can mitigate these issues. It’s crucial to stay aware of each spare part's condition to avoid costly repairs.

| Spare Part | Functionality | Common Materials | Maintenance Tips |

|---|---|---|---|

| Impeller | Transfers the energy from the motor to the fluid. | Cast Iron, Stainless Steel, Bronze | Regularly inspect for wear and tear. |

| Seals | Prevents fluid leakage around the shaft. | Rubber, PTFE | Check for cracks and replace as necessary. |

| Pump Housing | Holds all internal components of the pump. | Cast Iron, Aluminum | Ensure there are no external damages or corrosion. |

| Suction Strainer | Prevents debris from entering the pump. | Stainless Steel, Plastic | Clean regularly to avoid clogs. |

| Bearings | Supports rotational movement of the pump shaft. | Steel, Ceramic | Lubricate according to manufacturer specifications. |

| Mechanical Seal | Provides a leak-proof seal between the rotating and stationary parts. | Carbon, Ceramic, Elastomer | Inspect for wear and replace when leaks are noticed. |

| O-Rings | Seals connections to prevent leaks. | Rubber, Nitrile | Check and replace during regular maintenance. |

| Discharge Head | Directs fluid out of the pump. | Cast Iron, Steel | Inspect for corrosion and replace if damaged. |

| Gaskets | Seals joints to prevent leaks. | Rubber, Cork | Check for wear and replace as needed. |

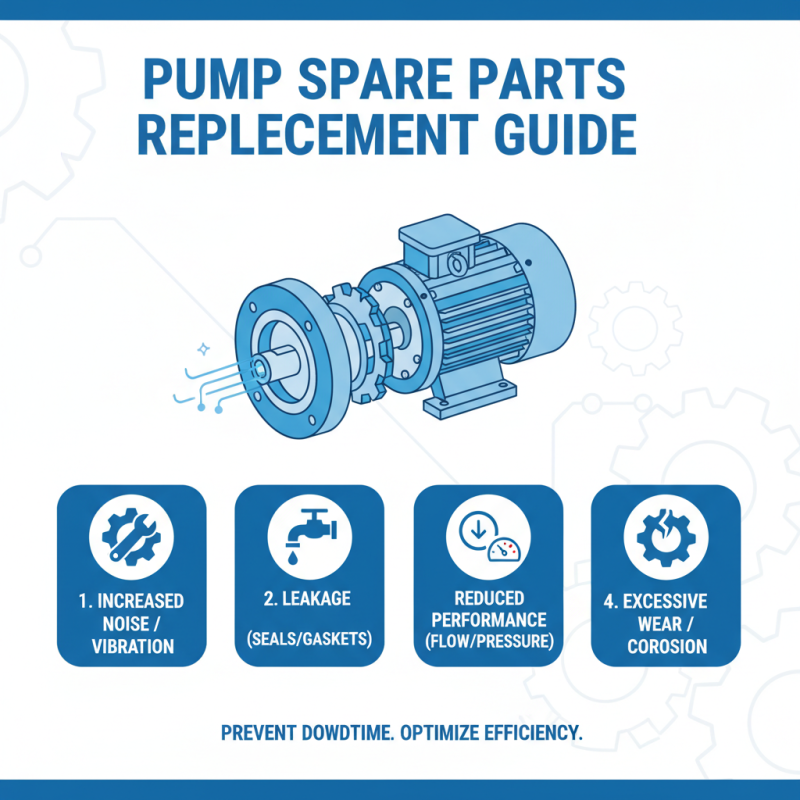

Pumps are essential components in many industries. Recognizing when to replace spare parts can prevent costly downtime. Common signs indicating the need for spare parts replacement are crucial for efficient operations.

Leaks often signal worn seals or gaskets. A study shows that 25% of pump failures stem from seal-related issues. Unusual noises can indicate bearing wear or cavitation. According to industry reports, nearly 30% of mechanical failures arise from these problems. If the pump vibrates excessively, this can lead to further damage.

Monitoring energy consumption is also vital. A drop in efficiency may suggest malfunctioning impellers or wear on components. Reports indicate that inefficiencies can increase operational costs by nearly 15%. Ignoring these signs can escalate maintenance issues and lead to potential system failures. Always be vigilant; regular inspections may help catch problems early.

When choosing spare parts for your pump, quality is paramount. Look for parts made from durable materials. This can significantly prolong the life of your pump. Consider the working environment too. For instance, harsh conditions may require specialized components. Research and gather information about the material composition of the parts.

Compatibility is also essential. Make sure the spare parts fit well with your existing pump model. It’s common to overlook this factor. Problems can arise from improper fitting. Another tip is to focus on suppliers with a good reputation. Customer reviews can provide insight into their reliability. Always ask for specifications and certifications.

Remember, opting for cheaper parts could lead to more expenses later. Case studies show that many have had to replace their pumps sooner than expected. It's an easy trap to fall into. Trust your instincts when assessing quality, and don't rush the buying process. Take your time to make informed decisions.

Maintaining pump components is crucial. Regular checks can prevent major failures. Start by inspecting seals and gaskets. If they show signs of wear, replace them immediately. This small step can save money in the long run.

Lubrication is another vital practice. Ensure that all moving parts are well-greased. Over time, grease can dry up or become contaminated. Periodically check for smooth movement. If things are too stiff, the pump might not perform well. It’s easy to overlook these details.

Monitor vibration levels during operation. Unusual vibrations can indicate problems. If a pump vibrates excessively, investigate further. Sometimes, a simple alignment can fix the issue. Other times, it might signal a need for more extensive repairs. Ignoring these signs can lead to more significant damage and downtime. Regular maintenance and quick fixes create a way to extend the life of your pump components.

This chart illustrates the importance of various spare parts in pump maintenance. Regularly monitoring and replacing these components can significantly extend the life of your pump system.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.