When it comes to plumbing and water distribution, choosing the right service water pump is critical. James Parker, an expert in the field, once said, "Selecting a service water pump can make or break your efficiency." His words resonate with many who face the challenge of finding the ideal pump for specific needs.

Service water pumps come in a variety of types and sizes, each designed for different applications. Understanding the complexities can be daunting. Each choice impacts utility, energy consumption, and overall performance. Sometimes, people overlook details, which leads to inefficiency. The right choice can elevate your system's reliability significantly.

As we delve into the top 10 service water pumps, it’s essential to consider various factors. Think about flow rate, pressure requirements, and energy efficiency. Often, users find themselves overwhelmed by options. Reflect on your situation carefully. A perfect fit is out there, ready to enhance your system.

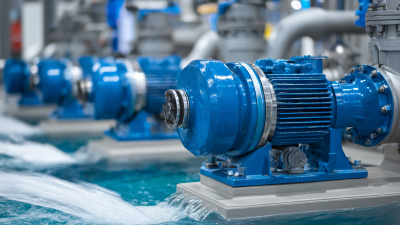

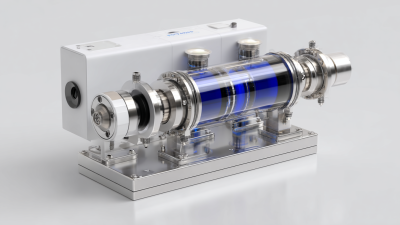

Service water pumps are crucial for various applications across industries. These pumps are designed to transfer water efficiently for systems requiring consistent flow. Each type of pump has specific features that cater to different needs. For instance, centrifugal pumps are often chosen for their ability to handle large volumes.

In many sectors, data shows that improper pump selection can lead to inefficiencies. The U.S. Department of Energy reports that up to 20% of energy costs come from inefficient pump operations. This highlights the need for careful consideration. Users often overlook the impact of pump design on their utility bills. Adjusting settings and pump types can drastically change performance.

Moreover, the lifespan of service water pumps varies significantly. Some may last only a few years if not maintained properly. Regular inspections and repairs can increase durability. Neglecting this aspect can result in unplanned downtimes. Studies indicate that scheduled maintenance can extend pump life by up to 30%. Choosing the right pump type is not just about flow rates but also about sustainability. Evaluating application requirements is essential for optimal performance.

When selecting a service water pump, several key features must be considered. Flow rate is crucial. It's measured in gallons per minute (GPM). For residential use, a flow rate between 5 to 15 GPM is typical. However, for commercial applications, pumps may need to deliver 20 GPM or more. This data can vary widely depending on specific needs.

Another important feature is the pump's head pressure. This refers to the height the pump can raise water. Many reports suggest that a good head pressure for most household needs ranges from 20 to 60 feet. Yet, higher is not always better. Pumps with excessive specifications can lead to increased energy costs.

Durability matters too. Many industry studies highlight that materials like stainless steel and thermoplastic offer better longevity. However, these materials can also drive up initial costs. It raises the question of investing more upfront for a potentially longer lifespan. Choosing the right pump can be a balancing act of cost, efficiency, and specific requirements.

When selecting a service water pump, performance and reliability are key factors. Different pumps handle various capacities and pressures. Some may excel in quiet operation, while others provide higher efficiency. Evaluating these aspects plays a vital role in meeting your specific needs.

Consider how the pump will be used. Will it serve a small residential area or a large commercial site? Not all pumps hold up under heavy usage. An effective pump should withstand constant wear without frequent breakdowns. Check the specifications carefully to avoid disappointment.

Installation processes vary as well. Some pumps are straightforward to set up, while others require professional installation. It's easy to make mistakes, especially if you're unfamiliar with pump mechanics. Understanding the installation requirements beforehand can save time and money. Investing in the right pump today can prevent issues down the line.

Maintaining your water pump is crucial for its longevity. Regular checks can save you from costly repairs. Begin with visual inspections. Look for leaks or corrosion around connections. Even small issues can escalate if ignored. Clean out any debris that may have accumulated in the intake area. This simple step enhances efficiency.

Check the oil level periodically. A low oil level can cause overheating. If the pump emits strange sounds, it might indicate wear. Addressing these concerns early prevents bigger failures later. Furthermore, keep the pump area clear. Overgrown vegetation can trap heat, leading to more significant problems.

Don’t forget to schedule professional maintenance. Experts can detect issues that may not be visible to you. Neglecting regular servicing might lead to unexpected breakdowns. Sometimes, it’s easy to overlook signs of wear. Ensure that seals and gaskets are in good condition. They play a vital role in avoiding leaks. Regular maintenance leads to optimal performance and peace of mind.

| Pump Model | Power Source | Flow Rate (GPM) | Max Head (Feet) | Efficiency (%) | Weight (lbs) | Maintenance Tips |

|---|---|---|---|---|---|---|

| Model A | Electric | 25 | 30 | 80 | 50 | Regularly check seals and bearings. |

| Model B | Gasoline | 30 | 25 | 70 | 60 | Clean fuel filter regularly. |

| Model C | Diesel | 20 | 35 | 75 | 70 | Inspect hoses for wear. |

| Model D | Electric | 40 | 40 | 85 | 45 | Change oil according to schedule. |

| Model E | Gasoline | 55 | 50 | 90 | 80 | Store in a dry place to avoid rust. |

| Model F | Electric | 15 | 20 | 65 | 30 | Inspect the power cord frequently. |

| Model G | Gasoline | 10 | 15 | 60 | 25 | Run periodically to prevent clogs. |

| Model H | Diesel | 35 | 45 | 83 | 75 | Keep an eye on temperature gauge. |

| Model I | Electric | 45 | 50 | 88 | 40 | Lubricate motor bearings regularly. |

| Model J | Gasoline | 20 | 30 | 77 | 65 | Check for leaks after use. |

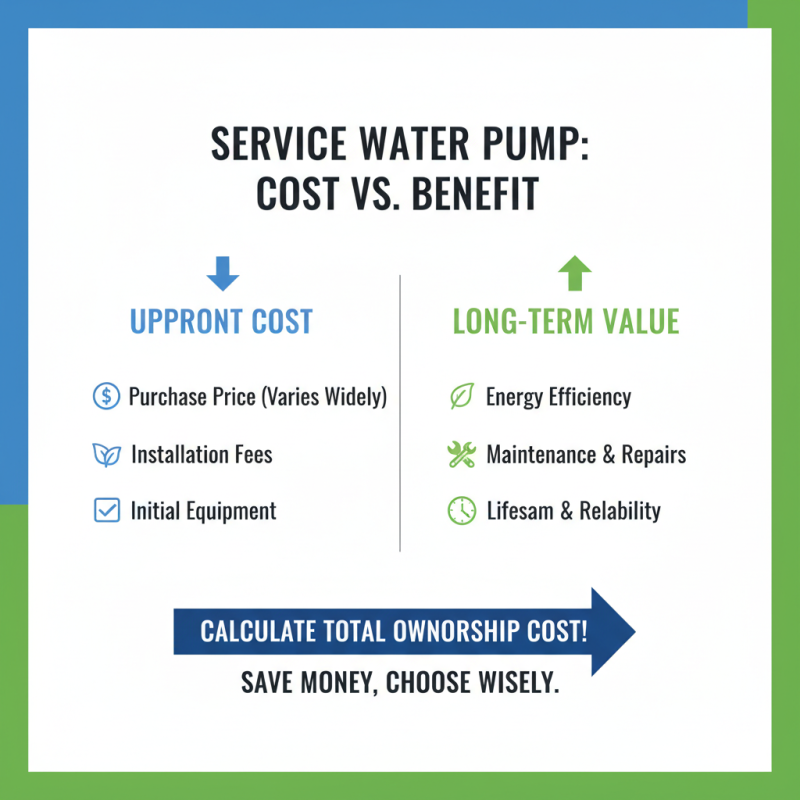

Choosing the right service water pump involves evaluating costs and benefits carefully. Many pumps vary significantly in price. Some might seem economical upfront but incur high maintenance costs later. Calculate these long-term expenses before making a decision.

Consider the features you really need. Some pumps offer advanced options that might not be necessary for your application. Is the extra money worth it? Sometimes, a simpler model is more effective. Investigate energy efficiency as well. It can impact your overall costs.

Reflect on your specific requirements. Do you need high pressure or flow rate? Think about how often the pump will be used. Short-term savings may lead to future regrets. Balancing cost with functionality is crucial for the best choice.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.