Gear pumps are essential components in various industrial applications, renowned for their reliability and efficiency in transferring fluids. According to the Hydraulic Institute, gear pumps account for approximately 20% of the global pump market, illustrating their significant role in sectors such as oil and gas, pharmaceuticals, and food processing. Their ability to handle diverse fluids, including viscous materials, makes them indispensable in manufacturing processes where precision and consistency are critical. Furthermore, a report by McKinsey highlights that the demand for gear pumps is expected to grow by 5% annually due to increasing automation and the need for efficient fluid management systems across industries. This underscores the importance of understanding their applications and benefits, as harnessing the power of gear pumps can lead to enhanced operational efficiency and cost savings.

Gear pumps are essential components in various industrial applications, renowned for their reliability and efficiency in transferring fluids. According to the Hydraulic Institute, gear pumps account for approximately 20% of the global pump market, illustrating their significant role in sectors such as oil and gas, pharmaceuticals, and food processing. Their ability to handle diverse fluids, including viscous materials, makes them indispensable in manufacturing processes where precision and consistency are critical. Furthermore, a report by McKinsey highlights that the demand for gear pumps is expected to grow by 5% annually due to increasing automation and the need for efficient fluid management systems across industries. This underscores the importance of understanding their applications and benefits, as harnessing the power of gear pumps can lead to enhanced operational efficiency and cost savings.

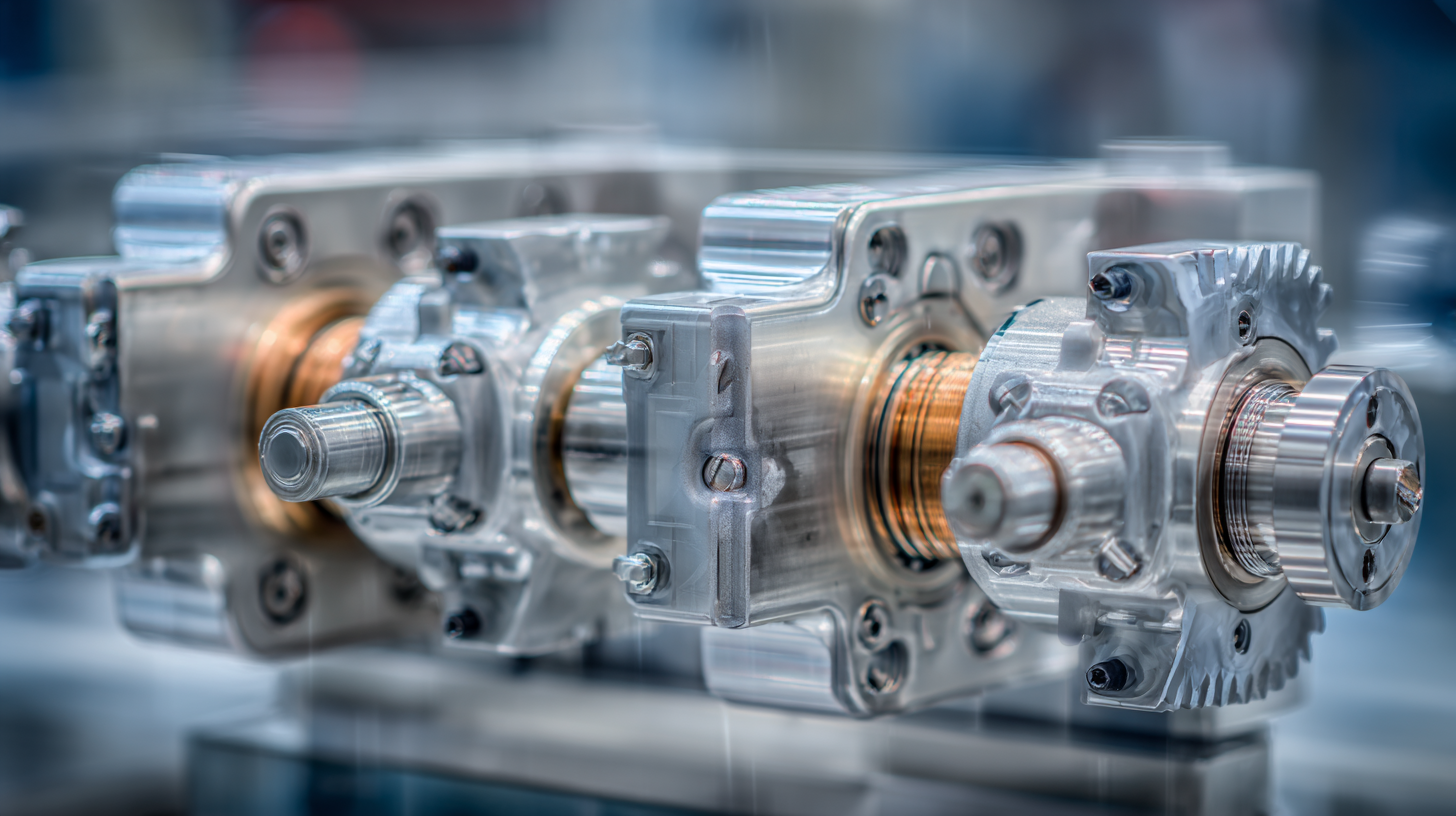

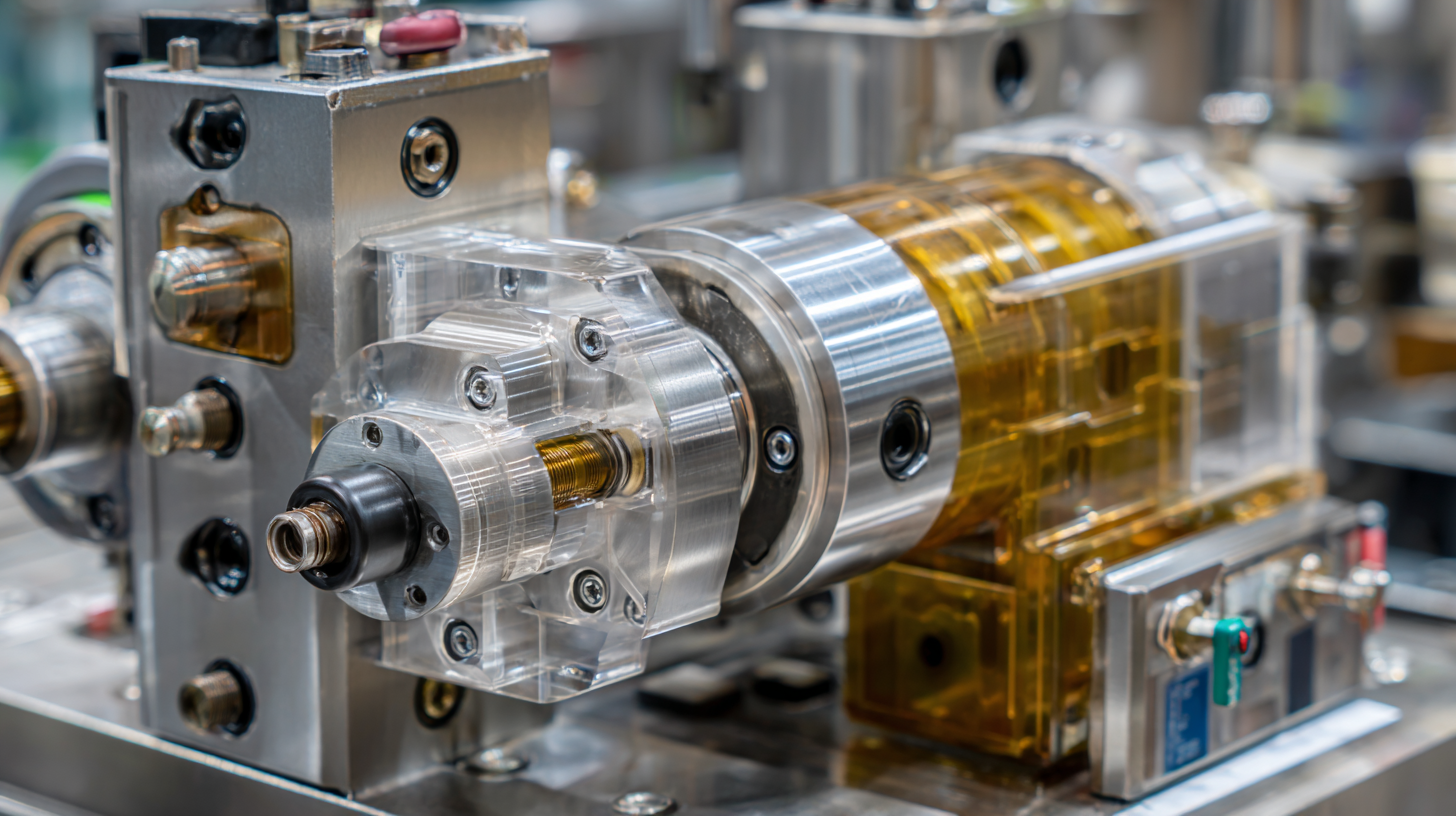

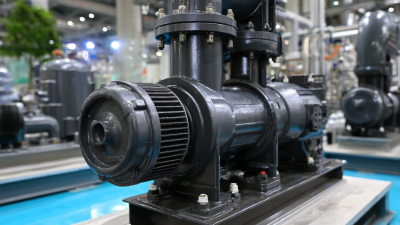

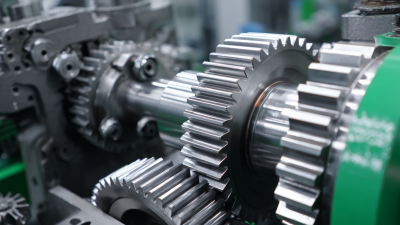

Gear pumps are a popular choice for fluid transfer in various industries due to their efficiency and reliability. The two primary types of gear pumps are external gear pumps and internal gear pumps. External gear pumps consist of two gears that mesh together, creating a low-pressure inlet and high-pressure outlet during operation. This design allows for a consistent flow rate, making them ideal for applications requiring steady liquid transfer, such as in hydraulic systems and oil transport.

Gear pumps are a popular choice for fluid transfer in various industries due to their efficiency and reliability. The two primary types of gear pumps are external gear pumps and internal gear pumps. External gear pumps consist of two gears that mesh together, creating a low-pressure inlet and high-pressure outlet during operation. This design allows for a consistent flow rate, making them ideal for applications requiring steady liquid transfer, such as in hydraulic systems and oil transport.

On the other hand, internal gear pumps feature an inner gear that rotates within an outer gear, creating cavities that trap and move fluid. This design is particularly advantageous for pumping viscous fluids, as the pumping action produces less turbulence, minimizing the risk of cavitation. Internal gear pumps are commonly used in applications that involve lubricating oils or chemical processing, providing effective handling of a wide variety of liquids. Understanding these common gear pump designs is crucial for selecting the right pump for specific industrial needs, ultimately enhancing system performance and productivity.

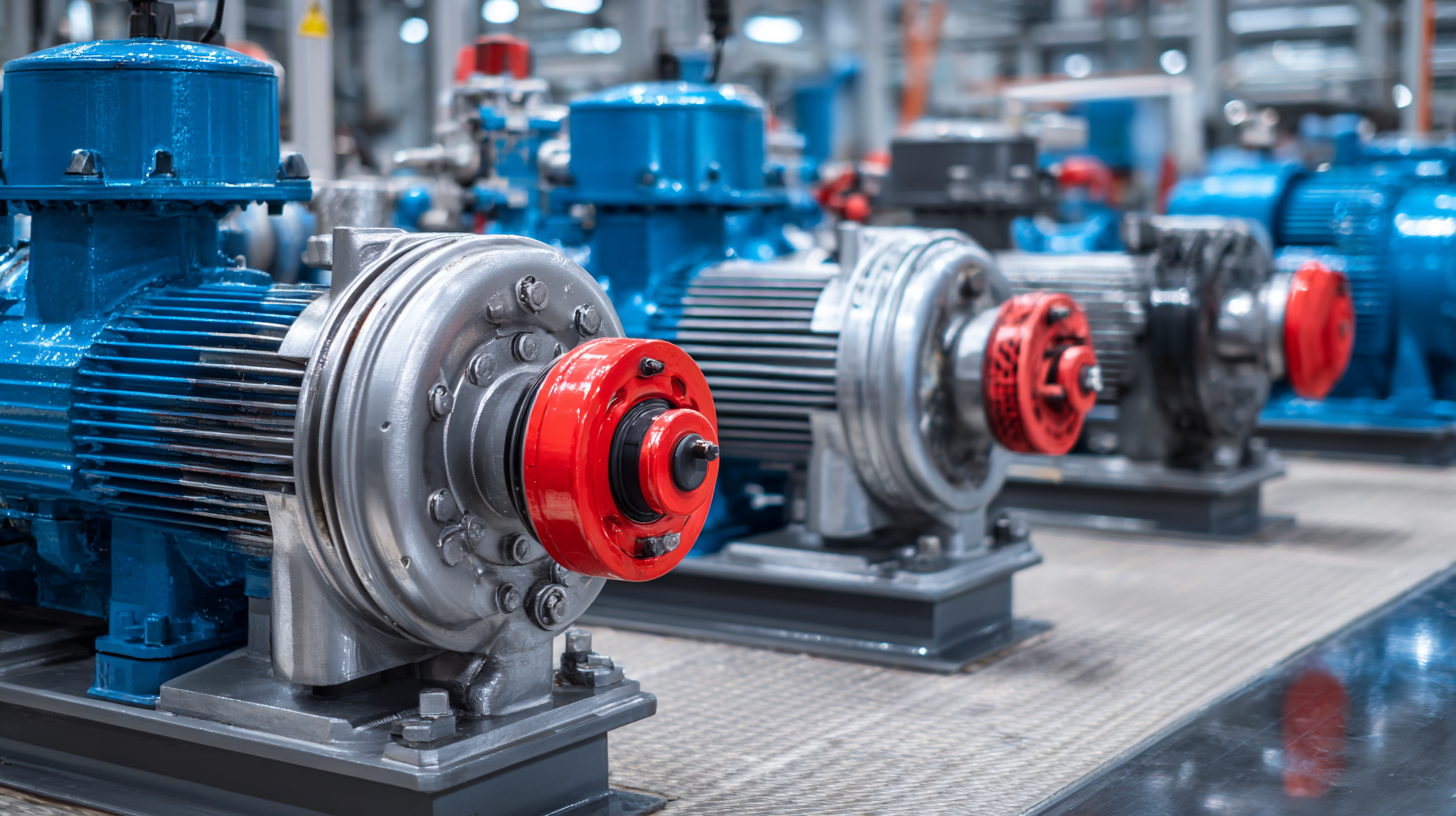

Gear pumps, renowned for their efficiency and reliability, find essential applications across a myriad of industries. In the automotive sector, for instance, gear pumps play a pivotal role in hydraulic systems, where they deliver precise amounts of fluid under high pressure. According to a report by Research and Markets, the global gear pump market is projected to grow at a CAGR of 4.3% from 2021 to 2026, reflecting its critical function in advancing automotive technologies.

In the oil and gas industry, gear pumps facilitate the transfer of viscous materials, ensuring smooth operations in exploration and production processes. The Energy Information Administration (EIA) notes that the demand for gear pumps in this sector is likely to rise due to increasing oil extraction activities, which require robust and consistent pumping solutions.

Tip: When selecting a gear pump for your specific needs, consider factors such as the viscosity of the fluid, desired flow rates, and the operating environment to maximize efficiency and lifespan.

In the food and beverage industry, hygienic gear pumps are essential for the transfer of liquids like oils, syrups, and dairy products. According to a study by Markets and Markets, the global food pump market is expected to reach $1.23 billion by 2026, driven by stringent regulations and the need for sanitary processing methods.

Tip: Always choose gear pumps that comply with industry standards and certifications to ensure safety and quality in food processing applications.

Gear pumps are widely recognized for their efficiency, reliability, and versatility, making them a staple in various industries. One of the primary benefits of gear pumps is their ability to handle high-viscosity fluids with minimal energy loss. This efficiency translates into reduced operational costs and enhanced throughput, as gear pumps can maintain consistent flow rates even under challenging conditions.

In addition to their efficiency, gear pumps are renowned for their reliability. Designed with fewer moving parts, these pumps require less maintenance and are less prone to wear and tear over time. This reliability is crucial in industries where downtime can lead to significant financial losses. Moreover, the versatility of gear pumps allows them to be adapted for numerous applications, from chemical processing to food and beverage production, further enhancing their value across different sectors. By choosing gear pumps, businesses can ensure optimal performance while minimizing risk and maximizing productivity.

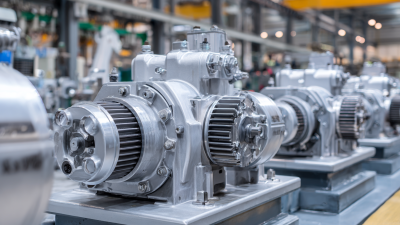

Gear pumps have emerged as a pivotal component in hydraulic systems, providing robust solutions for various industries. When comparing gear pumps to other pump types, such as centrifugal or diaphragm pumps, their advantages become evident. Gear pumps offer consistent flow rates and high pressure output, making them particularly suitable for applications requiring precise fluid control. Moreover, their simple design leads to lower maintenance costs, as they have fewer moving parts compared to other pump types.

Gear pumps have emerged as a pivotal component in hydraulic systems, providing robust solutions for various industries. When comparing gear pumps to other pump types, such as centrifugal or diaphragm pumps, their advantages become evident. Gear pumps offer consistent flow rates and high pressure output, making them particularly suitable for applications requiring precise fluid control. Moreover, their simple design leads to lower maintenance costs, as they have fewer moving parts compared to other pump types.

According to industry forecasts, the industrial pump market is projected to grow to $46.4 billion by 2024, with a compound annual growth rate of 5.3% from 2025 to 2034. This growth is driven by increasing demands from end-user industries and advancements in pump technology. Gear pumps play a crucial role in this landscape by providing reliable performance in hydraulic applications, ensuring enhanced efficiency across manufacturing processes.

Tip: When selecting a pump for your specific application, consider the operational environment. Gear pumps perform exceptionally well in high-viscosity fluids, making them ideal for industries like oil and gas, while other types may be better suited for lower viscosity applications. Always conduct a thorough analysis of your fluid characteristics and desired outcomes before making a decision.

Gear pumps are integral to various industries, offering reliable performance in fluid transfer applications. However, to maximize the efficiency and lifespan of these pumps, specific maintenance practices must be adhered to. Regular inspection and timely replacement of worn components can significantly enhance the operational reliability of gear pumps. According to market trends, the global internal gear pump market is expected to grow from USD 575 million in 2025 to USD 868 million by 2035, indicating a robust demand for efficient pumping solutions.

**Tips:** Ensure that oil levels are consistently monitored and changed according to the manufacturer's recommendations. This simple attention to oil maintenance can prevent excess wear and tear, allowing gear pumps to operate at peak performance.

Furthermore, keeping the gear pump and surrounding machinery clean is crucial. Contaminants can lead to premature wear and system failures. Regularly scheduled maintenance, coupled with a proactive approach to cleaning, can lead to improved reliability and cost savings.

**Tips:** Implement a routine cleaning schedule to prevent build-up of deposits that can hinder pump performance. This practice is essential for maintaining optimal functionality and ensuring longevity in your gear pump systems.

| Application | Industry | Benefits | Maintenance Practices |

|---|---|---|---|

| Fuel Transfer | Oil & Gas | High efficiency, Reliability | Regular lubrication, Seal checks |

| Chemical Processing | Chemical Industry | Corrosion resistance, Precise flow control | Regular inspections, Cleanliness checks |

| Hydraulic Systems | Manufacturing | Consistent pressure, Minimal pulsation | Fluid level monitoring, Filter replacement |

| Water Treatment | Water Management | Reliable flow rates, Low maintenance | Systematic testing, Equipment calibration |

| Food Processing | Food & Beverage | Hygienic operation, Gentle handling of products | Frequent cleaning, Inspection for wear |

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.